What Is a PCB Prototype Order?

A PCB prototype order refers to the fabrication (and optional assembly) of small-quantity printed circuit boards used to verify circuit design, functionality, and manufacturability before entering mass production. PCB prototype orders are a critical step in product development, R&D, and engineering validation.

Compared with volume production, PCB prototype manufacturing focuses on speed, flexibility, and engineering support, allowing design issues to be identified and corrected early.

Why PCB Prototype Orders Are Important

Placing a PCB prototype order helps engineers:

-

Validate circuit design and layout

-

Test electrical performance and functionality

-

Identify potential manufacturing issues early

-

Reduce overall development risk and cost

-

Accelerate time-to-market

A successful PCB prototype order provides confidence before committing to large-scale production.

PCB Prototype Order Process

A standard PCB prototype order process typically includes:

-

File submission

Gerber files, drill files, stack-up details, and special requirements. -

Engineering review (DFM/DFA)

Checks manufacturability and assembly feasibility. -

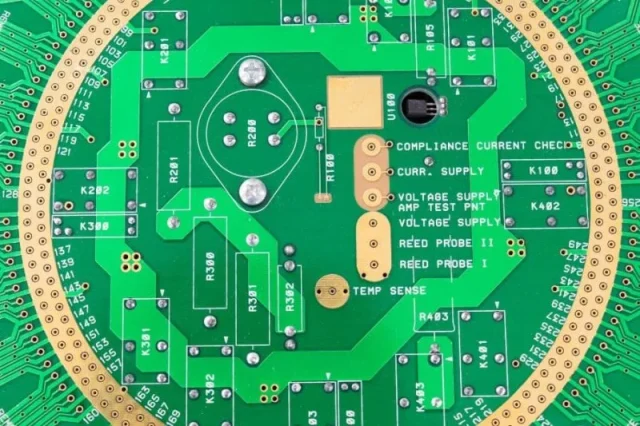

PCB prototype fabrication

Includes imaging, etching, drilling, lamination, and surface finishing. -

PCB assembly (optional)

SMT, THT, or mixed assembly for functional testing. -

Inspection and testing

AOI, electrical testing, and functional verification. -

Delivery

Secure packaging and fast shipment.

Clear communication during the PCB prototype order process ensures smooth execution.

Key Manufacturing Considerations for PCB Prototype Orders

To achieve reliable results, PCB prototype orders require attention to:

-

Material selection

FR-4, high-Tg laminates, Rogers, or hybrid materials depending on application. -

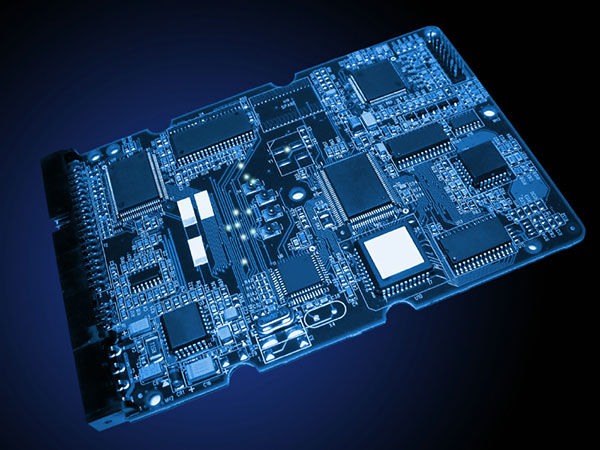

Layer count and stack-up

Single-layer, multilayer, HDI, rigid-flex, or high-frequency PCBs. -

Trace width, spacing, and impedance control

-

Surface finish options

ENIG, OSP, immersion silver, HASL, or hard gold. -

Tolerance and quality requirements

Experienced manufacturers provide engineering support to optimize prototype quality.

Lead Time Options for PCB Prototype Orders

PCB prototype orders offer flexible lead times:

-

Standard prototype lead time

Suitable for normal development schedules. -

Quick-turn PCB prototype orders

Ideal for urgent R&D or design verification. -

Small batch production

Bridges the gap between prototype and mass production.

Selecting the right lead time balances speed, cost, and technical requirements.

Applications of PCB Prototype Orders

PCB prototype orders are widely used in:

-

New product development and R&D

-

Functional and logic testing

-

RF and high-speed circuit validation

-

Medical and automotive electronics prototyping

-

Industrial control and IoT device development

They are essential across nearly all electronics industries.

Conclusion

A PCB prototype order is a crucial step in transforming a circuit design into a reliable, manufacturable product. With fast turnaround, flexible quantities, and strong engineering support, PCB prototype manufacturing enables engineers to test, refine, and optimize designs efficiently.

Choosing a reliable PCB prototype supplier ensures high-quality prototypes, reduced development risk, and a smoother transition to mass production.