In automated test environments, PCB fabrication alone is not enough. The performance of an ATE system heavily depends on the quality of ATE PCB Assembly, where component placement accuracy, solder integrity, and process control directly affect test stability and yield.

A professionally executed ATE PCB assembly ensures that the test board performs consistently across long test cycles and repeated device insertions.

What Is ATE PCB Assembly?

ATE PCB Assembly refers to the complete PCBA process for test boards used in Automated Test Equipment, including:

-

SMT and through-hole component assembly

-

High-pin-count connector installation

-

Mechanical reinforcement and inspection

These assemblies must meet stricter reliability standards than standard production PCBA.

Why ATE PCB Assembly Requires Special Expertise

ATE PCBs operate in demanding conditions:

-

Continuous electrical stress

-

Repeated mechanical loading

-

Long test durations

Improper assembly can lead to intermittent failures, false test results, and reduced test yield.

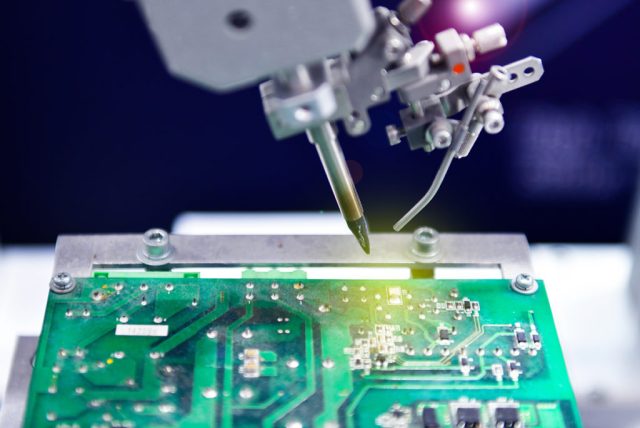

Component Placement Accuracy and Alignment

High-density ATE boards require:

-

Precise placement of fine-pitch ICs

-

Accurate alignment of sockets and connectors

-

Controlled coplanarity for test interfaces

Placement accuracy directly impacts signal quality and mechanical reliability.

Soldering Quality and Joint Reliability

Reliable solder joints are critical for ATE PCB assembly. Key considerations include:

-

Optimized reflow profiles

-

Robust solder fillet formation

-

Reinforced joints for high-stress components

High-quality soldering ensures long-term electrical stability.

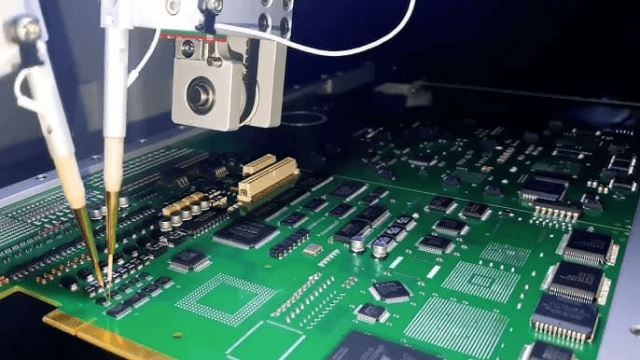

Handling High Pin Count and High-Speed Components

ATE PCB assemblies often include:

-

High pin count connectors

-

High-speed interface ICs

-

Power-hungry devices

Assembly processes must support dense layouts without introducing shorts or opens.

Mechanical Reinforcement and Structural Stability

ATE PCBs frequently experience mechanical stress. Assembly enhancements include:

-

Underfill or staking for large components

-

Reinforced mounting points

-

Controlled board flatness during assembly

These measures extend board life and test consistency.

Inspection, Testing, and Quality Control

Professional ATE PCB assembly includes:

-

AOI and X-ray inspection

-

Electrical continuity testing

-

Functional verification when required

Strict inspection prevents latent defects from entering test systems.

Typical Applications of ATE PCB Assembly

ATE PCB assembly services are widely used in:

-

Semiconductor functional and parametric testing

-

Production screening and reliability testing

-

Device characterization platforms

-

Advanced test development systems

Each application demands consistent and repeatable assembly quality.

Choosing an ATE PCB Assembly Partner

When selecting an ATE PCB assembly manufacturer, consider:

-

Experience with test and semiconductor PCBA

-

Capability for high pin count and fine-pitch assembly

-

Strong process control and traceability

-

Turnkey support from PCB fabrication to assembly

A reliable partner minimizes downtime and improves test efficiency.

Conclusion

ATE PCB Assembly is a critical factor in the success of automated test systems. Through precise component placement, robust soldering, and strict quality control, professional ATE PCB assembly ensures stable performance throughout the testing lifecycle.

Working with an experienced ATE PCB assembly supplier guarantees reliable operation from prototype validation to high-volume test deployment.