In the global electronics market, procurement decisions do more than affect cost—they shape product performance, development speed, and supply chain stability. Choosing a PCB supplier direct—a manufacturer that sells directly to customers without intermediaries—offers strategic advantages that extend beyond price alone.

A factory-direct PCB supplier enhances engineering collaboration, accelerates time to market, and ensures long-term quality and supply reliability.

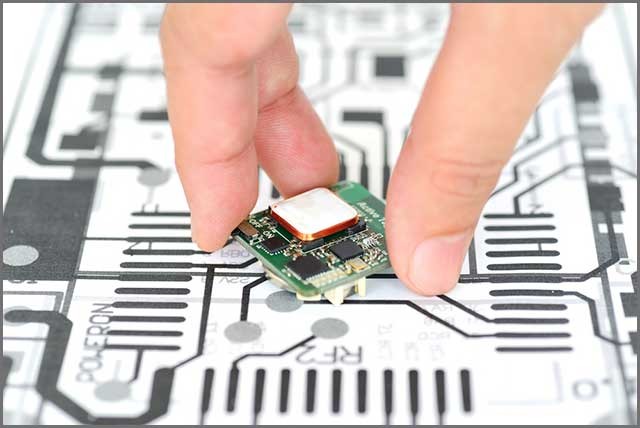

What Does PCB Supplier Direct Actually Mean?

A PCB supplier direct is a printed circuit board manufacturer that engages directly with customers throughout the PCB lifecycle—from design review and prototyping to volume production and quality assurance.

Unlike traditional distribution or trading channels, a PCB supplier direct:

-

Communicates design intent directly with engineers

-

Provides first-hand production insights

-

Avoids layered markups and opaque pricing

-

Controls fabrication quality from raw materials to shipment

This direct model puts technical clarity and performance ahead of middle-man profit.

Why Factory-Direct Matters for PCB Performance

A PCB supplier direct brings engineering expertise into the sourcing process. This improves PCB manufacturability and performance by:

1. Early DFM and Technical Feedback

Engineers at the factory analyze:

-

Stackup feasibility

-

Impedance and high-frequency performance

-

Material and tolerance trade-offs

This feedback reduces revision cycles and avoids costly redesigns.

2. Material and Process Transparency

Direct interaction ensures you choose the right materials (FR-4, Rogers, PTFE, etc.) for:

-

RF / high frequency performance

-

Controlled impedance needs

-

Thermal and mechanical stability

Factory direct suppliers explain how material choices affect cost and performance in real terms.

Cost Optimization Through Direct Supplier Relationships

A PCB price from a distributor often includes:

-

Agent or broker markups

-

Layered supply chain fees

-

Opaque cost components

A PCB supplier direct model eliminates these layers, delivering:

-

Transparent factory pricing

-

Custom cost breakdowns

-

Volume based pricing predictability

-

Engineering-driven value tradeoffs

This is especially important for complex boards like high frequency, multilayer, or controlled impedance PCBs where material and process choices significantly impact price.

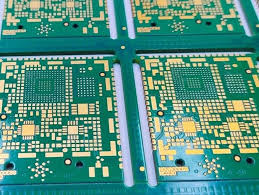

Quality Control and Accountability With PCB Supplier Direct

Quality assurance matters most when performance margins are tight—such as:

-

High speed digital traces

-

RF signal paths

-

Automotive / aerospace applications

A PCB supplier direct provides:

-

In-house AOI, X-ray, and electrical testing

-

Statistical process control (SPC)

-

Detailed traceability and compliance

-

Direct escalation pathways

If issues arise, responsibility stays within the manufacturer rather than bouncing between vendors and brokers.

Supply Stability and Long-Term Support

Working with a PCB supplier direct partner yields:

-

Predictable lead times

-

Better handling of priority orders

-

Flexible small batch / prototype runs

-

Scalable mass production planning

Factory-direct relationships help manage:

-

Seasonal material shortages

-

Tooling changeovers

-

Production bottlenecks

-

Forecast changes

This is crucial where delivery reliability is a competitive advantage.

Real Applications That Benefit from PCB Supplier Direct

A factory-direct model is especially valuable for:

-

High Frequency & RF PCBs

-

Controlled Impedance Designs

-

Multilayer and HDI Boards

-

Automotive Radar & ADAS Modules

-

Advanced IoT, 5G, mmWave Products

-

Aerospace & Military Electronics

These applications demand performance predictability, traceability, and process transparency—all hallmarks of a direct supplier relationship.

How to Choose the Right PCB Supplier Direct Partner

When evaluating a PCB supplier direct, look for:

- Direct engineering support

- Clear manufacturing cost breakdown

- Proven quality control systems

- Prototyping + scalable volume production

- Material and process expertise

- Traceable supply chain and compliance documentation

A strong partner improves risk management and strengthens product competitiveness.

Conclusion

Choosing a PCB supplier direct is not just a purchasing strategy—it’s a manufacturing partnership that enhances technical collaboration, cost clarity, quality control, and supply chain resilience.

Today’s competitive environments demand more than low bids: they demand predictable performance, engineering alignment, and scalable capability. Working directly with a PCB supplier allows development teams to innovate faster, ship reliably, and build products that truly perform.