What Is a Metal Core PCB (MCPCB)?

A Metal Core Printed Circuit Board (MCPCB) uses a metal substrate—typically aluminum, copper, or iron alloy—as the core layer instead of standard FR4 dielectric material.

Thanks to the high thermal conductivity of metal substrates, MCPCBs can efficiently dissipate heat generated by high-power electronic components, making them essential for:

-

High-power LED lighting

-

Power electronics

-

RF & microwave systems

-

Automotive and industrial electronics

At KKPCB, we manufacture aluminum, copper, and iron-alloy MCPCBs tailored to different thermal, mechanical, and cost requirements.

Why Metal Core PCBs Are Used for Thermal Management

Traditional FR4 PCBs have limited thermal conductivity (~0.3 W/mK).

Metal core PCBs dramatically improve heat dissipation:

| Material | Thermal Conductivity |

|---|---|

| FR4 | ~0.3 W/mK |

| Aluminum Core | ~130 W/mK |

| Copper Core | ~400 W/mK |

| Iron Alloy Core | Up to ~65 W/mK |

This allows MCPCBs to:

-

Reduce junction temperature

-

Improve reliability

-

Extend product lifespan

-

Support higher power density designs

Aluminum Core PCB (Aluminum MCPCB)

Typical Material Properties

-

Thermal Conductivity: ~130 W/mK

-

CTE: ~23 ppm/°C

-

Density: 2.7 g/cm³

-

Specific Heat: 0.9 J/g°C

-

Common Alloys: 5052, 6061, 2024

Key Advantages

-

Excellent heat dissipation for most applications

-

Low material and processing cost

-

Lightweight

-

Mature and stable PCB manufacturing process

-

Easy machining and stamping

-

Fully recyclable

Typical Thickness

-

0.5 – 6.0 mm

-

Most common: 1.0 – 2.0 mm

Typical Applications

-

LED lighting modules

-

Power supplies

-

Motor drivers

-

Solar inverters

-

Automotive electronics

KKPCB Recommendation

Aluminum MCPCBs offer the best balance of performance, manufacturability, and cost for most commercial and industrial designs.

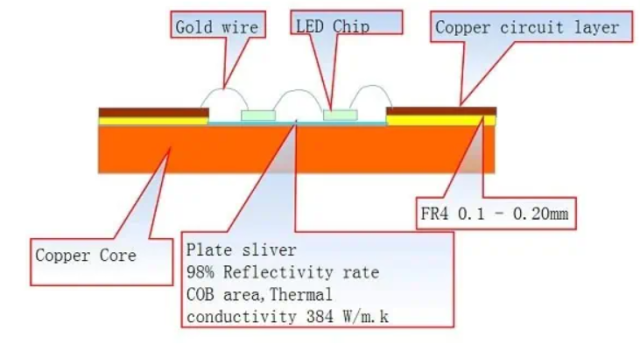

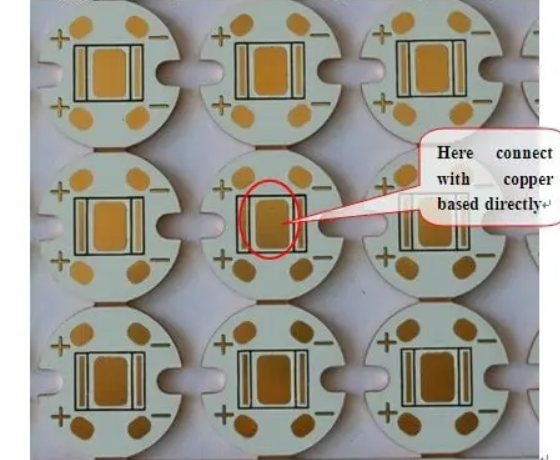

Copper Core PCB (Copper MCPCB)

Material Characteristics

-

Thermal Conductivity: ~400 W/mK

-

CTE: ~17 ppm/°C

-

Density: 8.9 g/cm³

-

Specific Heat: 0.39 J/g°C

Key Advantages

-

Exceptional heat dissipation performance

-

Ideal for extreme thermal conditions

-

Compatible with standard FR4 PCB processes

-

Excellent electrical conductivity

-

High-temperature soldering capability

-

Recyclable

Typical Thickness

-

0.25 – 4.0 mm

-

Common range: 0.5 – 2.0 mm

Typical Applications

-

High-power LED arrays

-

RF power amplifiers

-

Power modules

-

GaN / GaAs devices

-

High-density computing systems

Limitations

-

Significantly higher cost than aluminum

-

Increased weight

-

Requires nickel plating for solderability

KKPCB Insight

Copper MCPCBs are recommended only when maximum thermal performance is mission-critical.

Iron Alloy Core PCB (Ferroalloy MCPCB)

Iron alloy cores (nickel-iron, cobalt-iron, etc.) provide a mid-range solution between aluminum and copper.

Typical Properties

-

Thermal Conductivity: Up to 65 W/mK

-

CTE: 10–15 ppm/°C

-

Density: 7–8 g/cm³

-

Specific Heat: 0.44–0.46 J/g°C

Advantages

-

Higher thermal conductivity than aluminum

-

Lower cost than copper

-

Thin core with high mechanical strength

-

Compatible with FR4 manufacturing processes

Typical Thickness

-

0.1 – 3.0 mm

-

Common: 0.2 – 0.5 mm

Applications

-

LED lighting

-

Industrial electronics

-

Telecommunications equipment

-

Automotive modules

KKPCB Viewpoint

Iron alloy MCPCBs are ideal when cost and weight are constrained, but better thermal performance than aluminum is required.

Comparison Table: Metal Core PCB Materials

| Parameter | Aluminum | Copper | Iron Alloy |

|---|---|---|---|

| Thermal Conductivity | ~130 W/mK | ~400 W/mK | ≤65 W/mK |

| Cost | Low | High | Medium |

| Density | Low | High | Medium |

| Common Thickness | 1–3 mm | 0.5–2 mm | 0.1–0.5 mm |

| Best Use Case | Cost-driven thermal PCBs | Extreme heat dissipation | Balanced cost & strength |

Metal Core PCB Manufacturing Process (KKPCB Capability)

-

Metal Core Preparation

Cutting, punching, surface treatment -

Dielectric Layer Lamination

High-thermal-conductivity insulating films -

Circuit Formation

Photolithography, plating, etching -

Component Assembly

SMT soldering, silver sintering, TLP bonding -

Mechanical Integration

MCPCB as structural or heat-spreading element

Advantages & Limitations Summary

Aluminum MCPCB

✔ Cost-effective

✔ Lightweight

✖ Lower thermal performance than copper

Copper MCPCB

✔ Best thermal conductivity

✖ High cost and weight

Iron Alloy MCPCB

✔ Balanced performance

✖ Limited material options

Applications of Metal Core PCBs

-

High-power LED lighting

-

Power converters & inverters

-

Motor drivers

-

RF & microwave amplifiers

-

Servers & data centers

-

Aerospace & defense electronics

FAQ

Q1: How do I choose the right MCPCB thickness?

-

Thicker cores support higher power

-

Thinner cores reduce weight

-

Balance stiffness, cost, and layout requirements

Q2: What are common MCPCB manufacturing challenges?

-

CTE mismatch delamination

-

Dielectric voids

-

Precision drilling

-

Warpage after lamination

Q3: Do metal cores need electrical insulation?

Yes.

A dielectric layer is mandatory to prevent short circuits and enable signal routing.

Q4: Are there alternatives to metal core PCBs?

-

Thick copper FR4 PCBs

-

Thermal vias

-

Heat sinks & heat pipes

-

Liquid cooling plates

-

IMS (Insulated Metal Substrate) PCBs

Choosing the Right Metal Core PCB

At KKPCB, we help customers select the optimal MCPCB material based on:

-

Thermal requirements

-

Mechanical constraints

-

Frequency performance

-

Weight

-

Cost targets

Quick Selection Guide:

-

Aluminum Core PCB → Best overall value

-

Copper Core PCB → Maximum heat dissipation

-

Iron Alloy PCB → Balanced performance & cost

Contact KKPCB for professional MCPCB design & manufacturing support.