1. Why Thermal Conductivity of Metals Matters in PCB Applications

Metals are widely used in electronic devices and printed circuit boards (PCBs) due to their excellent electrical and thermal properties. However, not all metals conduct heat equally.

-

High thermal conductivity metals rapidly transfer heat and are ideal for heat dissipation

-

Low thermal conductivity metals restrict heat flow and act as thermal barriers or structural materials

In modern PCB design—especially for high-power, high-frequency PCB, and compact electronics—understanding the thermal conductivity of metals is essential for achieving reliable thermal management.

2. What Is Thermal Conductivity?

Thermal conductivity (k) is a fundamental material property that measures a material’s ability to transfer heat.

It is typically expressed in W/m·K (watts per meter per Kelvin).

In PCB and electronic system design, thermal conductivity directly affects:

-

Heat spreading efficiency

-

Component junction temperature

-

Long-term reliability

-

System power density limits

For most pure metals, thermal conductivity remains relatively stable over a wide temperature range.

For alloys, thermal conductivity may increase or decrease depending on composition and temperature.

3. Why Metals Conduct Heat So Well

Metals exhibit excellent thermal conductivity primarily due to the presence of free electrons.

Heat Transfer Mechanisms in Metals

-

Electronic conduction (dominant mechanism in solid metals)

-

Lattice vibration (phonon conduction)

-

Molecular collision conduction (in liquid or gaseous states)

The free movement of electrons enables metals to conduct heat far more efficiently than insulating materials such as polymers or ceramics.

This is why copper and aluminum are widely used in PCBs, heat sinks, and thermal interfaces.

4. Thermal Conductivity of Common Metals Used in PCBs

4.1 Copper – The Benchmark for Thermal Performance

-

Thermal conductivity: ~398 W/m·K

-

Typical applications:

-

Copper-clad laminates

-

Thick copper PCBs

-

Power planes and heat spreaders

-

Copper offers the highest thermal conductivity among commonly used PCB metals, making it ideal for high-current and high-power designs.

4.2 Aluminum – Lightweight and Cost-Effective

-

Pure aluminum thermal conductivity: ~235 W/m·K

-

Aluminum alloys: lower than pure aluminum

Aluminum is widely used in:

-

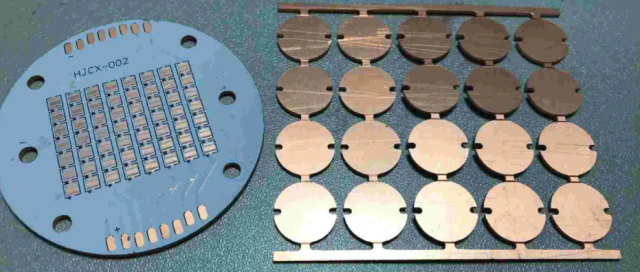

Metal core PCBs (MCPCB)

-

LED substrates

-

Heat sinks and enclosures

Its balance of thermal conductivity, weight, and cost makes aluminum a popular choice in electronic cooling solutions.

4.3 Carbon Steel

-

Thermal conductivity: ~45 W/m·K

Carbon steel offers much lower thermal conductivity than copper or aluminum.

It is primarily used for structural strength, not heat dissipation.

4.4 Stainless Steel – Very Low Thermal Conductivity

-

Thermal conductivity: ~15 W/m·K

Stainless steel has one of the lowest thermal conductivity values among common metals.

It is rarely used for heat dissipation in PCBs but is valuable for:

-

Structural components

-

Corrosion-resistant enclosures

-

Applications requiring thermal insulation

4.5 Bronze (Copper Alloy)

-

Thermal conductivity: ~50–120 W/m·K (composition-dependent)

Bronze provides moderate thermal conductivity and good mechanical stability.

Its performance depends heavily on copper content.

5. Metals with Low Thermal Conductivity: When Insulation Is an Advantage

Not all PCB-related applications require high heat transfer.

Low thermal conductivity metals are valuable when heat isolation and stability are required.

Typical Low Thermal Conductivity Metals

-

Stainless steel (~15 W/m·K)

-

Carbon steel (~45 W/m·K)

-

Certain bronze alloys

Advantages

-

Reduced heat transfer

-

Improved thermal stability

-

Better energy efficiency in structural designs

-

Safer operation near heat sources

In electronics, these metals are often used for frames, shields, housings, and mechanical supports, rather than thermal paths.

6. High vs Low Thermal Conductivity in PCB Design

| Application Requirement | Preferred Metal Type |

|---|---|

| Heat dissipation | Copper, Aluminum |

| Power electronics | Thick copper PCB, Metal core PCB |

| Structural strength | Steel, Stainless steel |

| Thermal isolation | Low thermal conductivity metals |

| LED & power modules | Aluminum or copper |

At KKPCB, material selection is always driven by thermal simulation, power density, and reliability requirements.

7. Applications Requiring High Thermal Conductivity Metals

Heat Exchangers

-

Automotive radiators

-

Power electronics cooling

-

Aerospace thermal systems

Radiators & Heat Sinks

-

CPU and GPU cooling

-

High-power LEDs

-

Power transistors

PCB Thermal Solutions

-

Metal core PCBs

-

Thick copper PCBs

-

Embedded copper blocks

-

Copper heat spreaders

8. Key Takeaway for PCB Engineers

-

High thermal conductivity metals (copper, aluminum) are essential for efficient PCB heat dissipation

-

Low thermal conductivity metals (steel, stainless steel) serve as thermal barriers and structural materials

-

Proper metal selection directly impacts PCB reliability, performance, and lifespan

9. KKPCB Thermal Management Capabilities

KKPCB provides:

-

Thick copper PCB manufacturing

-

Metal core PCB fabrication

-

High thermal conductivity PCB solutions

-

Material selection and DFM support

We help engineers balance thermal performance, manufacturability, and cost.

Contact KKPCB

Looking for high thermal conductivity PCB materials or metal-based PCB solutions?

Contact KKPCB today for expert engineering support and fast quotation.