A PCB quotation is only as accurate as the data you provide. For prototype runs, pilot batches, or mass production, the most efficient way to shorten the quoting cycle and avoid repeated confirmation is to submit complete engineering files at the beginning. At KKPCB, our engineering team evaluates every project based on the actual design data—ensuring precise pricing, correct material selection, realistic lead times, and manufacturability verification before production.

Why Complete Files Matter for Accurate PCB Quotation

PCB pricing depends on real specifications, not assumptions. Even small details—copper weight, stack-up, surface finish, impedance control, or tolerances—can shift the entire cost structure. When customers send incomplete data, quotation engineers must request additional information several times, delaying the process and risking misunderstandings.

Submitting all manufacturing files upfront allows the engineering team to:

-

Confirm the correct layer count and board dimensions

-

Identify controlled-impedance traces and required materials

-

Validate minimum drill sizes, hole counts, and via structures

-

Evaluate special processes (HDI, blind/buried vias, heavy copper, RF materials, etc.)

-

Calculate the exact fabrication cost and reliable delivery time

The more complete the data, the faster the quotation.

Essential Documents for a Fast and Accurate PCB Quote

To avoid delays, include the following engineering data:

1. Gerber Files

These define copper patterns, solder mask, silkscreen, drill data, board outline, and mechanical details. Gerber is the foundation of any PCB quotation.

2. BOM (Bill of Materials)

If assembly is required, the BOM allows us to check component availability, confirm sourcing methods, and provide PCB + PCBA combined pricing.

3. Layer Count & Stack-up Requirements

High-frequency, high-density, or power-heavy designs depend on material choice and layer structure. Including your preferred stack-up (or allowing KKPCB to propose one) ensures accurate cost and lead-time evaluation.

4. Manufacturing Requirements

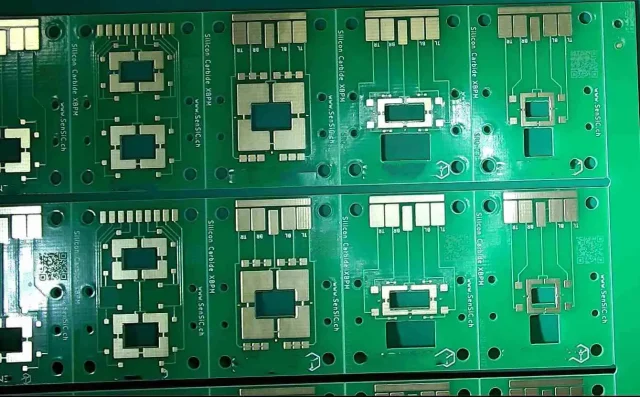

Such as copper weight, surface finish (ENIG, HASL, Immersion Silver), material type (FR4, Rogers, PTFE, Megtron, Ceramics), impedance control, via technology, controlled tolerances, and any environmental or reliability requirements.

Providing this information makes the quotation process extremely efficient.

How KKPCB Ensures a Precise and Transparent Quotation

Once we receive your Gerber, BOM, stack-up, and requirements:

-

Engineering verifies manufacturability (DFM)

-

Material and process engineers check RF, thermal, and mechanical constraints

-

Production planners calculate the most realistic lead time

-

Cost engineers generate exact costing without hidden adjustments

-

The final quotation includes detailed pricing for multiple quantities if needed

This approach eliminates pricing uncertainty and helps your R&D, purchasing, and production teams make fast decisions.

Efficient Quotation for Prototypes and Mass Production

Whether you are ordering 2-layer FR4 prototypes, high-layer server backplanes, mmWave RF boards, or automotive-grade HDI, the same rule applies—complete engineering data produces a faster, more precise quotation. KKPCB’s system is designed to support both rapid prototyping and scalable mass production with consistent quality and clear communication.