Accurate PCB quotation is never a guessing game. For OEMs, hardware startups and EMS partners working under compressed timelines, incomplete design files often lead to delays, cost deviations and unnecessary engineering iterations. Providing a complete engineering package—Gerber, layer stack-up, material specifications and fabrication notes—enables manufacturers to evaluate your design precisely and deliver consistent, reliable pricing for both prototypes and mass production.

1. Gerber Files Define the Physical Blueprint

Gerber data is the primary reference for PCB manufacturing. It outlines copper layers, solder mask, silkscreen, drill files and board outlines. When these files are complete and error-free, CAM engineers can immediately verify:

• trace widths and spacing

• copper distribution and impedance-critical areas

• drill density and via structures

• manufacturability risks such as acid traps, isolated copper or insufficient clearances

A complete Gerber package shortens front-end engineering time and avoids repeated clarification emails that slow down quotation.

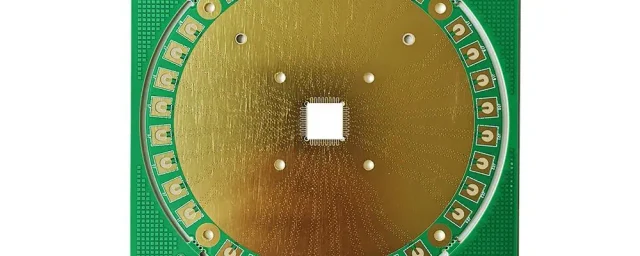

2. Layer Stack-Up Determines Cost, Performance and Manufacturability

The stack-up influences dielectric thickness, impedance accuracy, EMI behavior and thermal dissipation. For HDI, RF, high-current or hybrid material boards, stack-up information is essential for quoting:

• number of layers

• prepreg and core thickness

• blind/buried via structure

• sequential lamination cycles

• controlled impedance targets

Without this data, any quotation is only a rough estimate. With it, pricing becomes predictable and aligned with performance requirements.

3. Material Selection Defines Cost Structure and Electrical Behavior

Material type affects everything from RF loss to thermal expansion to reliability during reflow. Manufacturers need clear material information such as:

• FR-4 grade and Tg rating

• high-frequency materials (e.g., RO4350B, PTFE, hydrocarbon laminates)

• copper weight per layer

• thermal conductivity requirements

• UL rating or flammability class

A precise material list ensures that the manufacturer selects the correct suppliers and provides accurate pricing based on real availability and lead times.

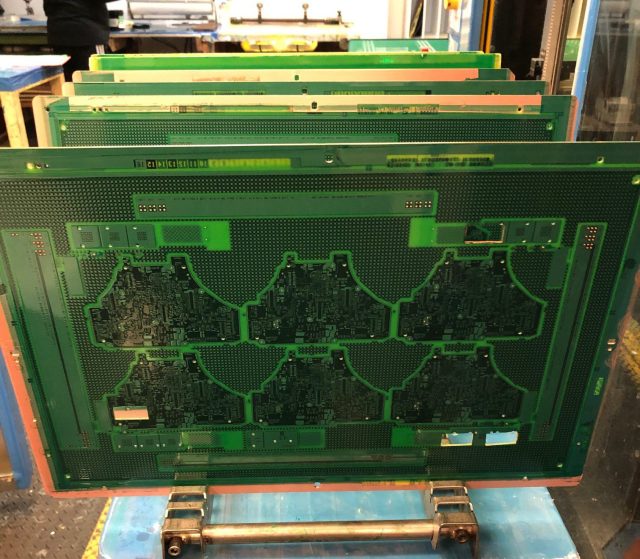

4. Full Engineering Specifications Avoid Unnecessary Variations

Even the best Gerbers can’t represent every detail. Engineering notes help finalize the quotation by clarifying:

• controlled impedance tolerance

• surface finish (ENIG, immersion silver, OSP, hard gold)

• solder mask requirements

• via fill/plug/cap types

• panelization, fiducials and tooling holes

• specific reliability requirements (IPC-6012 class, automotive AEC-Q standards, etc.)

Providing full specifications ensures consistency between prototype and mass production, reducing DFM risks.

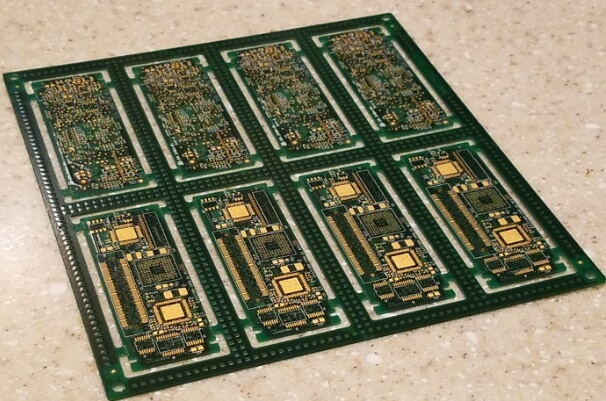

5. Complete Documentation Accelerates Production from Day One

When manufacturers receive a complete engineering package, the quotation becomes not only faster but also more aligned with real manufacturing capability. It minimizes revisions during prototype build and guarantees the same parameters can be scaled directly into volume production. This approach shortens your time-to-market, stabilizes electrical performance, and reduces unit cost variation across batches.