Aerospace navigation sensors operate in a realm where the margin for error is essentially zero. Whether guiding autonomous aircraft, stabilizing flight control modules, or supporting satellite-assisted positioning, these sensors rely on high-frequency PCB platforms engineered for absolute electrical stability. Achieving high-Q resonance and ultra-consistent impedance is not just a design preference—it is the foundation of navigation accuracy in harsh, vibration-prone flight environments.

High-Q Resonance: The Heartbeat of RF Sensing

In high-frequency aerospace sensors, the “Q-factor” determines how efficiently resonant circuits store and release energy. A high-Q response results in sharper signal discrimination, better sensitivity, and greater immunity to RF clutter.

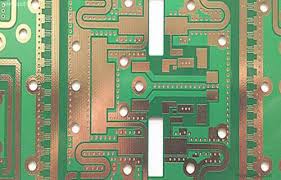

To reach this level of performance, PCB materials must contribute negligible dielectric loss. Low-Df laminates such as Rogers RO3000 series, RO4835, or PTFE-ceramic composites offer the clean signal pathways required to maintain resonance stability across extreme thermal swings at altitude.

Ultra-Stable Impedance for Navigation Precision

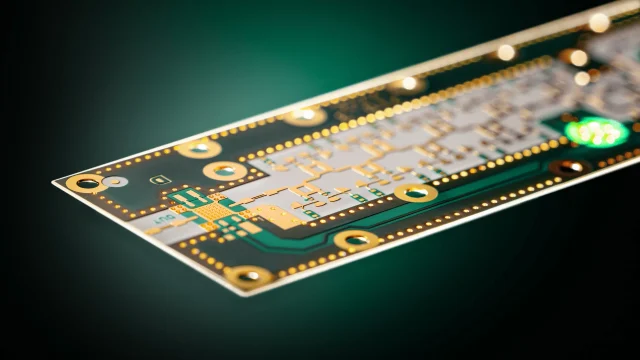

Aerospace navigation PCBs typically include microstrip lines, CPWG (coplanar waveguide) structures, and tightly matched sensing arrays. Any deviation in impedance—caused by temperature drift, vibration, or humidity—can distort the phase and amplitude of return signals.

Stability is achieved by combining:

-

tightly controlled dielectric thickness,

-

ultra-smooth copper foil to reduce high-frequency conductor loss,

-

multi-layer stackups engineered for consistent electromagnetic behavior.

When all these elements align, phase noise drops significantly, enabling more repeatable sensor readings and faster signal-processing convergence.

Material and Stackup Engineering for Flight Conditions

Aerospace PCBs are exposed to rapid thermal cycles, shock loads, and radiation exposure. To survive this gauntlet, PCB engineers must balance electrical needs with mechanical survivability.

Preferred material traits include:

-

High Tg (>200°C) and low CTE to resist warpage

-

Low moisture absorption to preserve RF stability during rapid altitude changes

-

Reinforced ceramic-filled PTFE substrates for ultra-low loss and phase stability

Stackups often integrate hybrid constructions—combining PTFE for RF layers with high-Tg FR-4 for digital control stages—to balance cost, robustness, and signal quality.

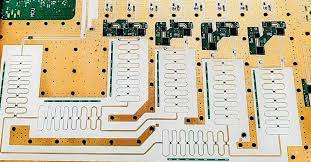

Mechanical Reinforcement for Vibration and Shock

Mounting aerospace sensors onto airframes exposes them to sustained vibration. PCB deformation can subtly change line impedance or fracture via structures.

Designers counteract this by using:

-

via-in-pad with filled microvias to strengthen interlayer connectivity

-

thicker copper in power stages to resist fatigue

-

edge-plating for structural rigidity

These reinforcements make high-frequency PCBs behave like a single monolithic block under stress, ensuring that the RF performance remains predictable.

Toward the Next Generation of Avionic Sensing

As aerospace navigation advances into higher-frequency bands—Ka-band, mmWave, and integrated multi-sensor fusion—the demand for high-Q RF structures and rock-solid impedance control will only intensify. PCB innovation is becoming as crucial as algorithm development in determining navigation accuracy.

The trajectory from here is clear: thinner dielectrics, cleaner copper, and smarter stackups will define the next frontiers of precision aerospace sensing.