Laptop Wi-Fi 6/7 systems operate with extremely tight RF tolerances: multi-band OFDMA, 4096-QAM, and Multi-Link Operation demand predictable impedance, low-loss transmission, and strict phase alignment. Traditional FR-4 substrates introduce thermal drift, inconsistent Dk, and elevated loss, making them insufficient for 6 GHz high-band routing.

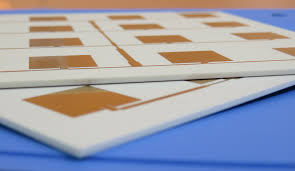

RO4350B PCBs solve these issues by combining ceramic-filled hydrocarbon dielectric stability with superior thermal conductivity and low Df. In Wi-Fi 6/7 laptop modules, RO4350B PCBs deliver cleaner RF paths, reduced insertion loss, and more stable MIMO calibration under high internal laptop temperatures.

This optimized article focuses entirely on RO4350B PCB engineering and its role in modern laptop Wi-Fi.

Engineering Challenges in Laptop Wi-Fi 6/7 Modules

Laptop RF architecture introduces four critical issues that directly influence RO4350B PCB design:

Thermal accumulation

CPU/GPU/VRMOS generate localized heating that detunes RF chains unless the RO4350B PCB substrate maintains stable Dk/Df.

Long RF routing distances

M.2 module → antenna traces can exceed 40–80 mm, amplifying loss unless RO4350B PCB low-loss properties are applied.

High-density EMI environment

Cameras, speakers, LVDS/eDP cables, touch sensors, and Bluetooth modules generate interference unless the RO4350B RF PCB includes isolation structures.

MIMO phase alignment sensitivity

Phase drift in FR-4 boards breaks calibration; RO4350B PCB maintains stable multi-band phase behavior.

RO4350B PCBs address these constraints across all three Wi-Fi bands (2.4 / 5 / 6 GHz).

Material Science Advantages of RO4350B PCB

RO4350B PCB laminates are engineered for broadband RF performance. Their dielectric uniformity and thermal behavior give them a clear advantage over FR-4 and standard mixed laminates.

| Parameter | RO4350B PCB Value | Engineering Advantage |

|---|---|---|

| Dk 3.48 | Stable RF impedance for Wi-Fi 6/7 routing | |

| Df 0.0037 | Low-loss transmission for long 6 GHz traces | |

| Thermal Conductivity 0.69 W/m·K | Lower FEM temperature on RO4350B RF boards | |

| CTE 32 ppm/°C | High via reliability across laptop thermal cycles | |

| Moisture Absorption 0.06% | Stable Wi-Fi behavior in humid regions | |

| Tg >280°C | Excellent multi-reflow reliability |

These characteristics make RO4350B PCBs ideal for high-bandwidth wireless systems and laptop antenna modules.

KKPCB Case Study — RO4350B PCB for Wi-Fi 6/7 Laptop Module

Background

A global laptop manufacturer required a stable RO4350B RF PCB solution to enhance 6 GHz performance and reduce EMI. Their existing FR-4 hybrid design suffered loss, thermal detuning, and inconsistent impedance.

Issues Found

-

6 GHz trace loss significantly exceeded target.

-

FEM overheating degraded EVM and MIMO phase stability.

-

EMI coupling from RF lines into the camera module.

-

Inconsistent impedance across FR-4 sections.

KKPCB RO4350B Engineering Implementation

-

Full RO4350B PCB RF structure on L1–L2.

-

Controlled copper roughness for RO4350B RF surfaces.

-

Ground isolation cuts and shielded microstrip structures.

-

Tight dielectric tolerance (±5 µm) across RO4350B layers.

-

Advanced TDR calibration using RO4350B-specific models.

Measured Performance Gains

| Parameter | FR-4 Hybrid | RO4350B PCB Solution |

|---|---|---|

| 6 GHz Insertion Loss | 1.01 dB | 0.73 dB |

| MIMO Phase Drift (25→70°C) | ±8.1° | ±3.4° |

| FEM Peak Temperature | 92°C | 78°C |

| EMI Into Webcam | –20 dB | –30 dB |

| TDR Ripple | ±6.5 Ω | ±2.8 Ω |

RO4350B PCBs showed decisive improvement in all RF and thermal metrics.

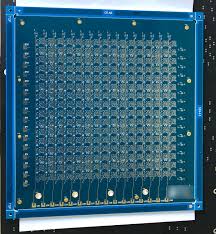

RO4350B PCB Stackup & RF Simulation

Stackup Example

| Layer | Material | Role |

|---|---|---|

| L1 | RO4350B PCB | 6 GHz microstrip, FEM output |

| L2 | RO4350B Prepreg | Solid RF ground plane |

| L3 | FR-4 High-Tg | Digital signals & control |

| L4 | FR-4 | Power and structural layer |

Simulation Workflow

-

HFSS: Optimized microstrip geometry for RO4350B loss characteristics.

-

ADS: Evaluated linearity and high-band EVM.

-

TDR: Validated line-to-line impedance using RO4350B models.

-

Thermal FEM: Verified FEM spreading and reduced hotspot temperature.

Routing Techniques on RO4350B PCB

-

VIA-in-pad + tight tolerance LNA/FEM placement

-

Segmented guard traces for high-band chains

-

Symmetric path lengths for 2×2/4×4 MIMO

-

RO4350B-based isolation for camera/BT coexistence

The RO4350B PCB substrate ensured stable impedance and predictable thermal response.

Environmental & Reliability Validation

| Test | Condition | RO4350B PCB Result |

|---|---|---|

| Thermal Cycling | –40 → +125°C | No delamination, stable Dk |

| Humidity 85/85 | 168 hours | Loss shift <0.05 dB |

| High-Temp Storage | 105°C | No dielectric drift |

| Vibration | 5–500 Hz | No S-parameter deviation |

| Multi-Reflow | 260°C ×3 | No warpage |

RO4350B PCB structures demonstrated excellent reliability for large-scale laptop manufacturing.

Engineering Summary

RO4350B PCBs offer clear advantages for Wi-Fi 6/7 laptop modules. Their stable dielectric properties, low-loss RF transmission, enhanced EMI suppression, and superior thermal reliability make them suitable for modern high-bandwidth wireless systems.

Key engineering benefits of RO4350B PCB in laptops:

-

Lower 6 GHz insertion loss

-

Improved MIMO phase stability

-

Better FEM thermal spreading

-

Stronger EMI immunity

-

Consistent impedance for long RF traces

-

Excellent durability under thermal and mechanical stress

KKPCB provides full RO4350B PCB stackup optimization, RF simulation, controlled manufacturing, and high-volume process stability, enabling laptop OEMs to achieve reliable Wi-Fi 6/7 performance.