Optimized Technical Article — BT-Epoxy in PCB Manufacturing

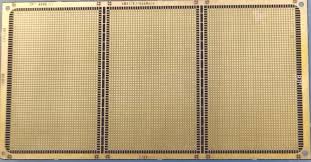

What is BT-Epoxy in PCB Manufacturing?

BT-Epoxy, short for Bismaleimide-Triazine resin, is a high-performance thermoset polymer widely used in advanced PCB fabrication. Sometimes referred to as Bisphenol-T epoxy, this material is produced by polymerizing BT monomers with epichlorohydrin, forming a tightly cross-linked resin system with excellent thermal, mechanical, and electrical performance.

As PCB requirements increase for high-density packaging, high-frequency signal integrity, and elevated operating temperatures, BT-Epoxy has become a preferred substrate material for IC substrates, HDI boards, aerospace electronics, and high-reliability systems.

Key Material Properties of BT-Epoxy

BT-Epoxy’s performance comes from its stable molecular network and optimized epoxy structure. Below are its core material properties:

1. Thermal Properties

-

Tg (Glass Transition Temperature): 180°C

Ensures stability for reflow soldering and multilayer HDI processing. -

Decomposition Temperature: 325°C

Supports extreme-temperature environments. -

Coefficient of Thermal Expansion (CTE): 27 ppm/°C

Provides dimensional stability for fine-pitch packaging. -

Thermal Conductivity: 0.35 W/m·K

Suitable for dense IC packaging where heat removal is critical.

2. Electrical Properties

-

Dielectric Constant (Dk): 3.7 @ 1 GHz

Stable dielectric behavior for high-speed digital and RF circuits. -

Dissipation Factor (Df): 0.014

Lower signal loss than conventional FR-4. -

Volume Resistivity: 10⁷ MΩ·cm

-

Surface Resistivity: 10⁷ MΩ

Excellent insulation for high-frequency designs. -

Dielectric Strength: 1200 V/mil

Supports high-voltage and high-density designs.

3. Mechanical Properties

-

Peel Strength: 1.56 N/mm

Strong copper adhesion for multilayer reliability. -

Flexural Strength: 99.88 MPa

-

Young’s Modulus: 31.9 GPa

Rigid and dimensionally stable. -

Density: 1.2 g/cm³

Lightweight yet mechanically strong.

4. Environmental and Chemical Properties

-

Moisture Absorption: <0.05%

Critical for stable electrical performance. -

UL94 V-0 Flame Rating

High flame retardancy for safety-critical applications. -

Chemical Resistance

Suitable for harsh environments and solvent exposure.

Applications of BT-Epoxy Substrate Material

BT-Epoxy’s balance of thermal, mechanical, and electrical properties makes it ideal for:

1. High-Density Interconnect (HDI) and IC Substrates

Used in:

-

BGA substrates

-

CSP/FC packages

-

High-I/O semiconductor packaging

2. Aerospace & Defense Electronics

Withstands:

-

High vibration

-

Thermal cycling

-

Radiation and harsh environments

3. Automotive Electronics

Ideal for:

-

Under-hood control modules

-

Radar systems

-

High-temperature environments

4. High-Frequency and High-Speed Electronics

Stable Dk/Df makes BT-Epoxy suitable for:

-

RF modules

-

5G infrastructure

-

High-speed digital backplanes

5. Industrial and General Electronics

Used for:

-

Structural composites

-

Adhesives

-

Encapsulation and coatings

Advantages of BT-Epoxy

BT-Epoxy is selected over FR-4 and other epoxy systems due to:

High Thermal Stability

Consistent performance during high-temperature reflow and long-term operation.

Outstanding Electrical Performance

Low Dk/Df ensures reliable high-speed signal integrity.

Excellent Mechanical Strength

Maintains structural reliability for fine-pitch multilayer designs.

Superior Chemical & Moisture Resistance

Ideal for harsh and humid environments.

Limitations and Challenges

Despite its advantages, BT-Epoxy has considerations:

-

Higher cost than standard FR-4

-

More brittle compared to modified epoxy systems

-

Requires precise curing conditions

-

Performance drop when approaching extreme temperatures >320°C

Engineers must balance performance and cost based on application needs.