1. Engineering Overview / Abstract

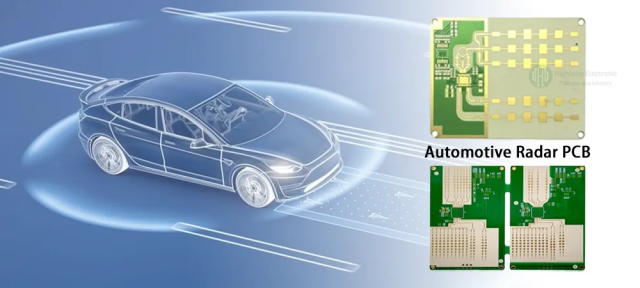

High-frequency automotive radar front-end modules operating at 77–79 GHz demand PCB substrates that combine low insertion loss with precise phase stability under harsh environmental conditions. PTFE PCB laminates, with a dielectric constant Dk = 2.10 ± 0.03 and loss tangent Df = 0.0007 @10 GHz, provide the electrical and thermal stability required for consistent radar performance.

KKPCB applies advanced lamination techniques, copper surface optimization, and hybrid stackup design to ensure PTFE PCBs maintain impedance control and phase-coherent signal transmission across compact multilayer radar modules, supporting reliable detection in ADAS systems.

2. Engineering Context & Technical Challenges

Automotive radar front-end modules using PTFE PCBs face several key challenges:

| Challenge | Root Cause | Impact |

|---|---|---|

| Impedance drift | Layer misalignment | Increased VSWR, reduced antenna efficiency |

| Insertion loss variation | Copper roughness and resin distribution | Lower RF SNR |

| Phase instability | Dk fluctuation under thermal load | Reduced radar resolution |

| EMI coupling | Dense multilayer routing | Cross-talk between transmit/receive channels |

These issues directly affect radar detection accuracy, range resolution, and signal integrity in ADAS applications. Maintaining low-loss transmission and phase consistency is critical for reliable automotive radar operation.

3. Material Science and Performance Characteristics

PTFE PCB laminates offer significant advantages over conventional FR-4 substrates in automotive radar applications:

| Parameter | PTFE PCB | FR-4 | Advantage |

|---|---|---|---|

| Dk | 2.10 ± 0.03 | 4.5 | Stable impedance, low reflection |

| Df | 0.0007 @10 GHz | 0.02 | Ultra-low insertion loss |

| CTE | 17 ppm/°C | 70 ppm/°C | Thermal stability and phase coherence |

| Tg | 280 °C | 130 °C | High-temperature endurance for automotive cycles |

Low Dk and Df support minimal insertion loss, while controlled CTE ensures phase consistency across –40 °C to +125 °C, meeting automotive radar reliability requirements.

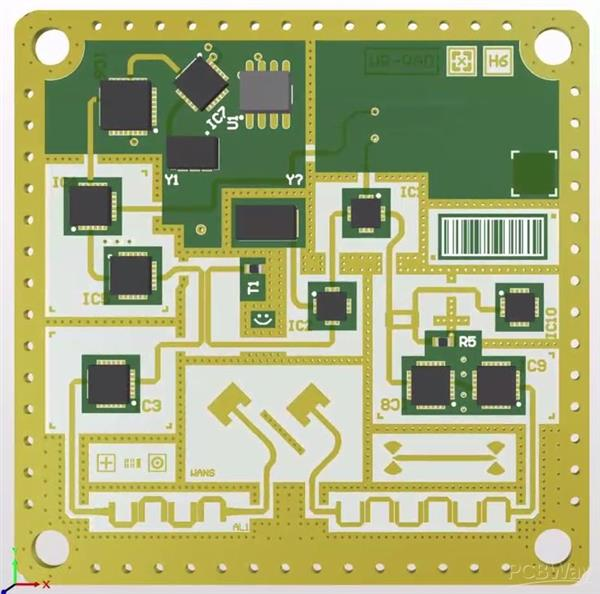

4. KKPCB Engineering Case Study — Automotive Radar Front-End

Client & Application Context:

A Tier-1 automotive supplier needed PTFE PCBs for 77 GHz radar modules in ADAS, targeting <0.25 dB/in insertion loss and phase deviation <1° across operating temperatures.

Engineering Problem:

Conventional FR-4 stacks could not maintain impedance stability under thermal cycling or vibration, resulting in signal degradation and inconsistent radar range resolution.

-

4-layer hybrid PTFE + prepreg stackup with optimized lamination

-

Controlled copper roughness (Ra < 0.8 µm) to reduce conductor-induced loss

-

HFSS and TDR simulations for impedance and phase verification

-

Inline thermal cycling and vibration validation of all panels

Measured Results:

| Parameter | Target | KKPCB Result |

|---|---|---|

| Insertion Loss | <0.25 dB/in | 0.22 dB/in |

| Impedance | ±3 Ω | ±1.7 Ω |

| Phase Stability | ±1° | 0.6° |

| Thermal Warpage | <0.1 mm/100 mm | Pass |

KKPCB achieved <0.6° phase deviation from –40 °C to +125 °C and maintained low-loss performance under mechanical vibration, ensuring consistent radar performance.

5. Stackup Design & RF Implementation

KKPCB implemented a 4-layer hybrid PTFE + prepreg stackup with precise via alignment and copper roughness control (Ra < 0.8 µm). HFSS and TDR simulations confirmed impedance within ±2 Ω and phase deviation <1° across 77–79 GHz. Hybrid lamination mitigated CTE mismatch between PTFE and copper layers, providing consistent RF performance in compact automotive radar front-end modules.

6. Environmental & Reliability Validation

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | –40 °C ↔ +125 °C, 1000 cycles | No delamination, ΔDk < 0.01 |

| Vibration | 5–500 Hz, 8 h/axis | No cracks, phase stable |

| Humidity | 85 °C / 85% RH, 1000 h | Df drift < 0.0001 |

| Mechanical Stress | Connector insertion 500 cycles | No impedance drift |

These results demonstrate that PTFE PCBs maintain low-loss transmission, impedance control, and phase consistency under automotive environmental conditions.

7. Conclusion — Engineering Reliability Integration

PTFE PCBs deliver low-loss transmission and precise phase consistency for automotive radar front-end modules. KKPCB’s hybrid lamination, copper surface optimization, and inline RF validation ensure thermal reliability, phase stability, and long-term performance, supporting ADAS and high-frequency radar applications.

8. Contact / CTA

Contact KKPCB Engineering Team for custom PTFE PCB stackup design, impedance verification, and reliability validation in automotive radar, satellite payloads, and other high-frequency RF modules.