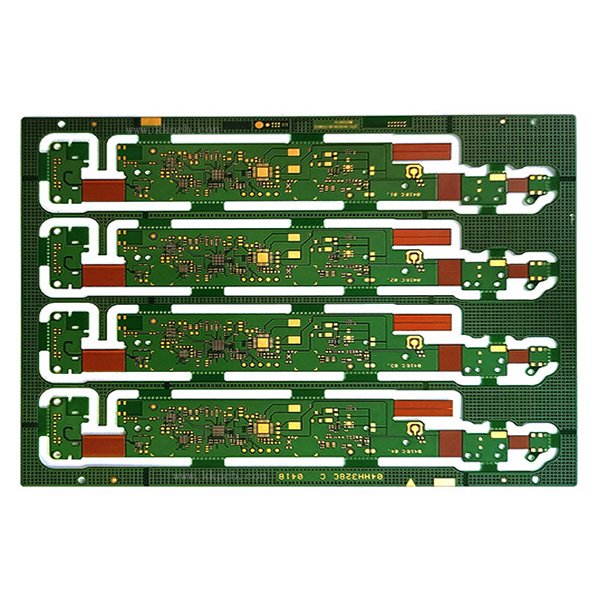

Product Category: Multi-Layer Rigid-Flex PCB

Structure: 3F + 5R (8-layer 2-step HDI)

Minimum Line/Spacing: 0.1/0.1 mm

Minimum Hole Size: 0.1 mm

Applications: High-end industrial sensor control, advanced electronics, aerospace, medical devices

KKPCB Manufacturing Capabilities

At KKPCB, we specialize in designing and manufacturing high-reliability rigid-flex PCBs. Our capabilities include:

-

Layer Count: 1–16 layers (currently producing up to 8-layer HDI rigid-flex PCB)

-

Materials: PI (0.5–2 mil), PET, PEN

-

Copper Thickness: 1/3 oz – 2 oz

-

NPTH Hole Tolerance: ±0.025 mm

-

PTH Hole Tolerance: ±0.05 mm

-

Finished Board Thickness Tolerance: ±0.01 mm

-

Minimum Line/Space: 0.05/0.05 mm

-

Surface Finishes: Anti-oxidation, ENIG, Immersion Gold, Lead-Free HASL, Electroless Tin

-

Ni/Au Thickness: Ni: 2.54–6 μm, Au: 0.025–0.125 μm

With years of experience in rigid-flex PCB design and production, KKPCB provides full DFM/DFT support, helping clients optimize their designs for manufacturing, assembly, and long-term performance.

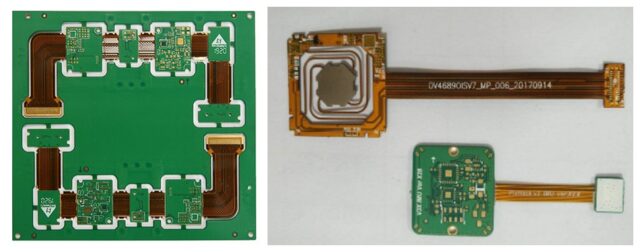

What is a Rigid-Flex PCB?

A Rigid-Flex PCB combines rigid PCB layers and flexible PCB layers into a single board through advanced lamination processes. Flexible sections are designed to bend, while rigid sections provide structural durability. This hybrid design allows:

-

3D assembly in limited spaces

-

Weight reduction

-

High reliability under dynamic or harsh conditions

Rigid-Flex PCBs are widely used in industrial control, medical electronics, military, aerospace, and high-end consumer devices.

Advantages of KKPCB Rigid-Flex PCBs

-

Space-Saving Design: Flexible sections allow folding and stacking to minimize device volume.

-

Durability: Resistant to high/low temperatures, fire, and chemical exposure.

-

Flexibility: Supports repeated bending without affecting electrical performance.

-

Enhanced Reliability: Larger soldering areas reduce potential failures compared to pure flexible PCBs.

-

Ease of Assembly: Reduces assembly errors and time, improving product lifespan.

-

Weight Reduction: Optimizes product weight without compromising performance.

-

Customizable Solutions: Supports complex geometries for specialized industrial applications.

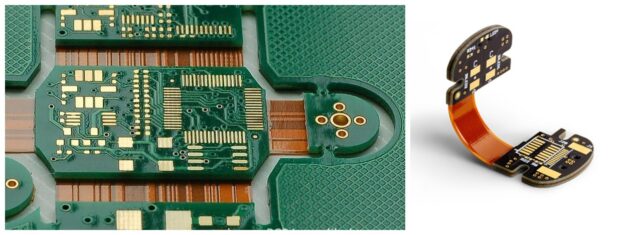

KKPCB Rigid-Flex PCB Design Guidelines

Our engineers follow strict design rules to ensure high reliability:

-

Via and Hole Placement: Avoid vias in high-flex regions; maintain safe distances from stiffeners.

-

Pad & Via Design: Use teardrop-shaped pads and mechanical anchors for durability.

-

Circuit Layout: Flex layers use smooth curved traces; avoid overlapping top and bottom layer circuits in bending regions.

-

Copper Pour & Planes: Optimize copper distribution to balance flexibility and electrical performance.

-

Rigid-Flex Transition: Ensure smooth conductor paths; avoid PTH in critical flex areas.

-

Bending Radius: Minimum radius is calculated based on thickness and number of layers: single-layer ≥6×T, double-layer ≥12×T, multi-layer ≥24×T; absolute minimum 1.6 mm.

For detailed guidelines, KKPCB follows IPC-D-249 and IPC-2233 standards to ensure reliable and high-quality manufacturing.

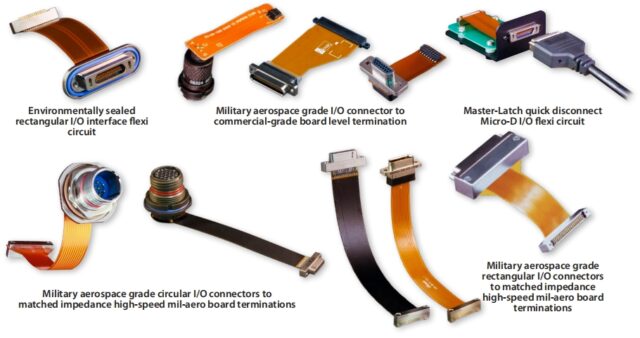

Applications of KKPCB Rigid-Flex PCBs

Our 8-layer rigid-flex HDI PCBs are widely used in:

-

Industrial Sensors & Controllers – High-precision monitoring and control

-

Medical Devices – Pacemakers, diagnostic equipment, wearable medical electronics

-

Automotive Electronics – ADAS modules, in-car sensors, radar systems

-

Aerospace & Defense – High-reliability, lightweight, and compact electronics

-

Consumer Electronics – Cameras, laptops, smartphones, printers, and more

KKPCB rigid-flex PCBs maximize space utilization, reduce weight, and improve signal reliability, making them ideal for cutting-edge electronics.

Why Choose KKPCB?

-

Expertise: Over 20 years of experience in rigid-flex PCB design and production

-

Advanced Manufacturing: Support for 2–16 layer rigid-flex PCBs, high-density HDI, and precise tolerances

-

Custom Design Support: DFM/DFT analysis for optimized reliability and performance

-

High-Quality Standards: Strict IPC-compliant processes and surface finishes

With KKPCB, your rigid-flex PCB projects—from prototyping to mass production—receive professional design, high-quality manufacturing, and reliable technical support.

Contact KKPCB today to discuss your custom rigid-flex PCB needs and achieve superior performance for your high-end electronics applications.