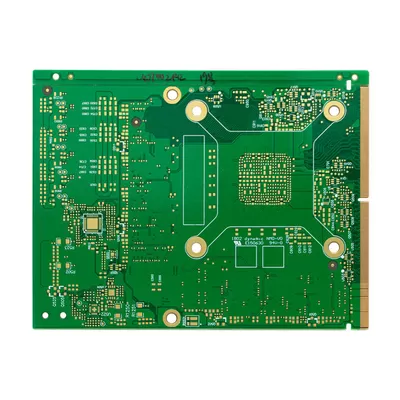

What Is 5G Module PCB Assembly?

5G Module PCB Assembly refers to the complete process of assembling electronic components onto high-frequency printed circuit boards used in 5G wireless communication modules. This includes RF PCB fabrication, component placement, soldering, testing, and final module integration.

5G module PCBA supports high-speed data transmission, low latency communication, and stable signal performance required by next-generation wireless networks.

Technical Challenges of 5G Module PCB Assembly

5G communication modules operate at high frequencies and require advanced assembly technology. Several key challenges must be addressed during 5G module PCB assembly:

High-Frequency Signal Integrity

5G RF modules require controlled impedance routing and low-loss materials to maintain signal quality.

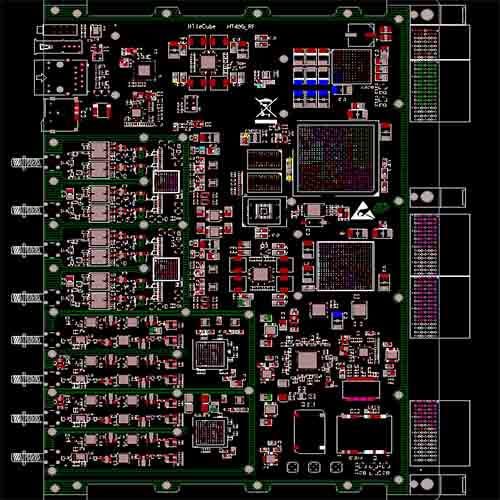

High Component Density

5G modules often include highly integrated chipsets, RF components, and antenna connections, requiring precision SMT placement.

Thermal Management Requirements

High-power RF components generate heat, requiring efficient thermal design and assembly control.

Fine Pitch Component Assembly

5G modules frequently use BGA, QFN, and other fine-pitch packages that demand high assembly accuracy.

RF Shielding and EMI Control

Proper shielding structures are necessary to maintain stable wireless performance.

5G Module PCB Materials

Material selection is critical for 5G module PCB assembly. Common materials include:

-

Rogers high-frequency laminates

-

Taconic RF materials

-

Panasonic Megtron high-speed materials

-

Hybrid RF + FR-4 stack-ups

-

Low loss dielectric materials

These materials ensure stable RF signal transmission and impedance control.

5G Module PCB Assembly Process

Professional 5G module PCB assembly typically includes the following stages:

Engineering Review and DFM Analysis

Design files and BOM undergo manufacturability review to optimize assembly reliability.

High-Frequency PCB Fabrication

RF PCBs are produced with controlled impedance and precise stack-up structures.

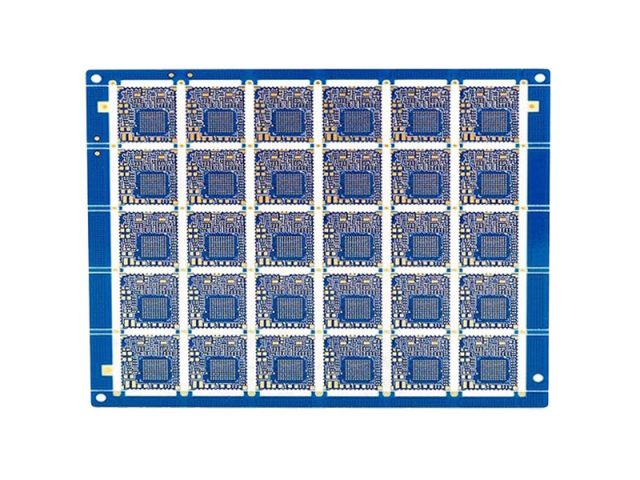

SMT Assembly Process

Automated SMT machines perform accurate placement of high-density RF and digital components.

Reflow Soldering

Advanced temperature profiles ensure reliable solder joint quality for sensitive RF components.

Inspection and Quality Control

Multiple inspection technologies are used, including:

-

Automated Optical Inspection (AOI)

-

X-ray inspection for hidden solder joints

-

RF performance verification

-

Functional testing

Final Assembly and Packaging

Completed 5G modules are assembled, tested, and packaged according to customer requirements.

Quality Assurance in 5G Module PCB Assembly

Reliable 5G module PCB assembly suppliers implement strict quality control systems, including:

-

Incoming component verification

-

Process control and traceability

-

RF signal testing and validation

-

Thermal and environmental reliability testing

-

IPC manufacturing standards compliance

These quality procedures ensure consistent product performance.

Applications of 5G Module PCB Assembly

5G module PCB assembly is widely used in advanced wireless communication systems, including:

-

5G base station communication modules

-

5G small cell communication systems

-

IoT wireless communication devices

-

Automotive 5G connectivity modules

-

Industrial wireless automation systems

-

Smart city infrastructure

-

Satellite and high-speed communication equipment

-

Consumer 5G networking devices

These applications require high reliability and stable RF performance.

Advantages of Professional 5G Module PCB Assembly Services

Working with an experienced 5G module PCB assembly provider offers several advantages:

-

Advanced RF PCB manufacturing capability

-

Precision high-density SMT assembly

-

Controlled impedance verification

-

Reliable component sourcing support

-

Faster production turnaround

-

Comprehensive testing and quality assurance

Professional assembly services help accelerate product development and production.

How to Choose a 5G Module PCB Assembly Manufacturer

When selecting a 5G module PCB assembly partner, companies should evaluate:

-

High-frequency PCB fabrication capability

-

RF assembly experience

-

Fine-pitch SMT assembly technology

-

Quality certification and testing capability

-

Supply chain and component sourcing stability

-

Engineering and DFM support capability

An experienced manufacturer ensures stable product performance and efficient production.

Conclusion

5G Module PCB Assembly is a critical manufacturing solution supporting high-speed wireless communication systems. By combining high-frequency PCB fabrication, precision SMT assembly, and advanced RF testing, 5G module PCB assembly ensures reliable signal transmission and stable product performance.

Partnering with a professional 5G module PCB assembly manufacturer helps companies achieve faster product development, consistent quality, and efficient production for advanced communication applications.