1. What Is SMT Assembly?

Surface Mount Technology (SMT) is one of the most widely used methods in modern PCB assembly. Unlike through-hole assembly, where component leads are inserted into drilled holes, SMT components are directly mounted onto the surface of a bare printed circuit board (PCB).

This method simplifies the PCB manufacturing process, reduces production time, and allows for the use of smaller and more delicate components — making it ideal for high-density, compact PCB designs.

2. Main Steps in the SMT PCB Assembly Process

The SMT PCB assembly process consists of several automated and highly precise steps that ensure quality and efficiency.

Step 1: Preparing and Inspecting the PCB and Components

Before assembly begins, both the bare PCB and electronic components must be inspected. Engineers verify that the PCB design and circuit layout meet functional and dimensional requirements to ensure successful assembly.

Step 2: Cleaning the PCB

If your PCB fabrication and assembly occur at different facilities, make sure the assembler performs thorough PCB cleaning. Dust or oxidation can affect solder joint quality, so cleanliness is crucial for reliable SMT PCB manufacturing.

Step 3: Solder Paste Printing and Inspection

A stainless-steel stencil aligned with the PCB layout is used to apply solder paste precisely on the pads. Correct stencil thickness, paste type, and application pressure are critical. After printing, an automated inspection checks for misalignment, excess, or insufficient solder paste.

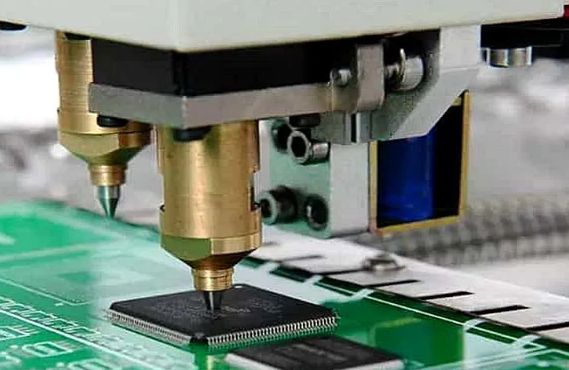

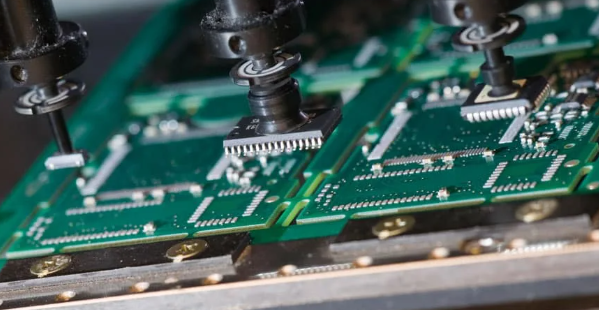

Step 4: Component Placement

Automated pick-and-place machines accurately mount SMD components onto the PCB based on the programmed layout. This stage demands precision — even minor placement errors can lead to rework. A pre-soldering inspection ensures every component is correctly positioned before soldering.

Step 5: Reflow Soldering

In this stage, the assembled PCB passes through a reflow oven, where controlled heat melts and solidifies the solder paste, permanently bonding components to the board. Maintaining proper temperature profiles ensures reliable solder joints and prevents thermal damage.

Step 6: Final Inspection and Testing

After soldering, the PCB undergoes AOI (Automated Optical Inspection) to detect solder defects or misaligned components. Depending on the product requirements, functional testing or manual inspection may also be conducted. These steps guarantee the quality and performance of the finished PCB assembly.

3. Advantages and Disadvantages of SMT PCB Assembly

Advantages

-

Fast and Efficient Production: SMT allows for high-speed, automated assembly, reducing manufacturing time.

-

Compact Design: Enables smaller and lighter PCBs ideal for portable electronics.

-

Cost-Effective: Fewer steps and reduced labor make SMT assembly more economical.

-

Supports Fine-Pitch Components: Perfect for mounting tiny and delicate SMD parts.

-

Scalable: Suitable for medium to large-scale production runs.

Disadvantages

-

Heat Sensitivity: SMT joints may weaken under extreme heat or vibration.

-

Mechanical Stress Limitations: Less durable under high-pressure or harsh environments.

-

Difficult Manual Repair: The small component size makes rework and inspection challenging.

4. When to Use and When to Avoid SMT PCB Assembly

Consider SMT PCB Assembly If:

-

Your PCB design involves dense or compact layouts.

-

You require mass production with consistent quality.

-

The end product operates under moderate temperatures.

-

You are using miniaturized or fragile components.

Avoid or Combine with Through-Hole Assembly If:

-

The PCB includes large, heavy, or high-power components.

-

You’re producing small prototype batches.

-

The device must withstand extreme mechanical or thermal stress.

5. Final Thoughts

The SMT PCB assembly process is the backbone of today’s electronics manufacturing. From smartphones to industrial controllers, this automated assembly technology offers speed, accuracy, and cost efficiency.

However, every project is unique. To ensure optimal results, it’s best to work with a professional PCB assembly manufacturer experienced in both SMT and through-hole technologies. A skilled team ensures your PCB assemblies meet the highest standards of quality and reliability.