Rogers RT/duroid 5880 is one of the most widely used microwave and millimeter-wave PCB substrates, known for its ultra-low dielectric loss and stable electrical performance. It is extensively applied in radar systems, satellite communications, 5G infrastructure, automotive radar, aerospace, and high-speed digital circuits.

In this article, KKPCB provides a comprehensive technical overview of RT/duroid 5880, covering:

-

Material composition

-

Electrical, mechanical, and thermal properties

-

Available laminate formats

-

Typical applications

-

Comparison with other RF substrates

-

Practical PCB design and manufacturing guidelines

-

Frequently asked questions

1. What Is Rogers RT/duroid 5880?

Rogers RT/duroid 5880 is a ceramic-filled PTFE (polytetrafluoroethylene) composite laminate, specifically engineered for high-frequency RF and microwave PCB applications.

Material Composition

The substrate consists of:

-

PTFE polymer matrix – provides excellent electrical insulation and thermal stability

-

Proprietary inorganic ceramic filler – tailors dielectric properties while preserving PTFE advantages

This composite formulation delivers:

-

Exceptionally stable dielectric constant across frequency and temperature

-

Ultra-low dielectric loss

-

Low Z-axis coefficient of thermal expansion (CTE)

-

Good mechanical rigidity suitable for double-sided and multilayer PCBs

2. Dielectric Properties of RT/duroid 5880

Dielectric performance is the most critical parameter for RF PCB materials. RT/duroid 5880 excels in this area.

Key Dielectric Parameters

-

Dielectric Constant (Dk): 2.20 ± 0.02

-

Loss Tangent (Df) @ 10 GHz: 0.0009

Unlike many substrates whose Dk varies significantly with frequency, RT/duroid 5880 maintains consistent performance from microwave to millimeter-wave bands.

Electrical Advantages

-

Easier impedance control

-

Higher Q-factor circuit designs

-

Lower insertion loss

-

Improved signal integrity at high frequencies

This makes RT/duroid 5880 ideal for high-Q resonators, antennas, filters, and low-noise RF front-end circuits.

3. Electrical, Mechanical & Thermal Properties

Electrical Properties

-

Volume Resistivity: 1 × 10¹⁴ ohm·cm

-

Surface Resistivity: 5 × 10¹⁴ ohms

-

Dielectric Strength: 3.0 × 10⁶ V/m

Mechanical Properties

-

Flexural Strength: 20,000 psi (138 MPa)

-

Tensile Strength: 10,000 psi (69 MPa)

-

Compressive Strength: 30,000 psi (207 MPa)

-

Density: 2.2 g/cm³

Thermal Properties

-

Thermal Conductivity: 0.71 W/m·K

-

Coefficient of Thermal Expansion (CTE): 17 ppm/°C

-

Max Continuous Operating Temperature: 170°C

-

Decomposition Temperature: >280°C

-

Water Absorption: <0.02%

These characteristics ensure excellent dimensional stability, thermal reliability, and environmental resistance.

4. Available Forms & Thickness Options

Sheet Laminates

Standard Sheet Sizes

-

12 × 18 in

-

18 × 24 in

-

24 × 36 in

Standard Thicknesses

-

0.005″, 0.010″, 0.015″, 0.020″

-

0.025″, 0.030″, 0.060″, 0.125″

(Custom thicknesses available upon request)

Roll Laminates

-

Widths: 12″, 24″, 48″

-

Standard Length: 250 ft (76 m)

-

Thickness Range: 0.005″ – 0.062″

This flexibility supports antenna arrays, large panels, and volume RF production.

5. Bonding & Multilayer PCB Options

Fusion Bonding (PTFE-to-PTFE)

-

No adhesive required

-

Bond strength > 2000 psi

-

Void-free interfaces

-

Superior electrical and mechanical integrity

-

Thinner, lighter multilayer boards

Recommended for high-performance RF and aerospace designs.

Adhesive Bonding

Compatible bonding materials include:

-

Rogers RO3000 / RO4000 series prepregs

-

Thermoset polyimide films

-

Epoxy-based bonding layers (e.g., FR-4 hybrid stacks)

Used for:

-

Mixed dielectric stack-ups

-

Metal-backed or heat-sink PCBs

-

Complex multilayer structures

KKPCB supports both bonding methods depending on performance and cost requirements.

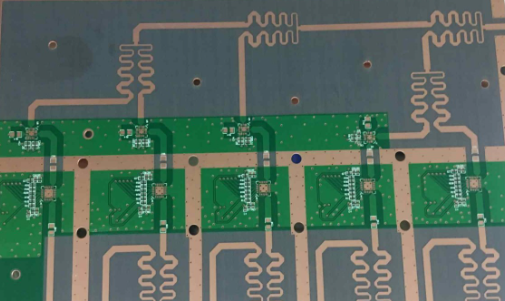

6. Typical Applications of RT/duroid 5880 PCBs

-

Radar Systems – antennas, phased arrays, RF modules

-

Aerospace & Defense – satellites, avionics, flight systems

-

5G & Wireless Infrastructure – base stations, test equipment

-

Automotive Radar – ADAS, collision avoidance systems

-

High-Speed Digital (20+ Gbps) – SERDES, backplanes

-

Medical RF Devices – MRI coils, RF ablation systems

7. RT/duroid 5880 vs Other RF PCB Materials

| Material | Dk | Loss Tangent | Key Features |

|---|---|---|---|

| RT/duroid 5880 | 2.20 | 0.0009 | Ultra-low loss, best RF performance |

| RT/duroid 6002 | 2.94 | 0.0012 | Higher Dk, compact RF designs |

| Rogers RO3003 | 3.00 | 0.0013 | Balanced RF performance |

| Rogers RO4003C | 3.38 | 0.0027 | Cost-performance tradeoff |

| Nelco 4000-13SI | 3.66 | 0.0021 | Lower cost, mid-level RF |

| Taconic RF-60A | 6.15 | 0.0028 | High Dk applications |

| Rogers TMM10i | 9.80 | 0.0020 | Very high Dk designs |

RT/duroid 5880 remains the gold standard for ultra-low-loss RF circuits.

8. Design Guidelines for RT/duroid 5880 PCBs

Stack-Up Design

-

Use symmetrical layer structures

-

Balance copper distribution to minimize warpage

-

Follow Rogers lamination guidelines

Trace Width & Spacing

-

Minimum spacing ≥ 3× dielectric thickness

-

Wider traces for higher current and reduced loss

Impedance Control

-

Expect ±8% manufacturing tolerance

-

Use field solvers with Rogers material models

Signal & Power Integrity

-

Isolate RF from noisy digital circuits

-

Use solid reference planes and proper decoupling

Thermal Management

-

Use thermal vias under power devices

-

Ensure airflow and copper heat spreading

Manufacturing Considerations

-

Clearly define drilling, milling, and lamination cycles

-

Use Rogers-qualified PCB manufacturers like KKPCB

9. Rogers RT/duroid 5880 – FAQ

Q1: Can RT/duroid 5880 be used for multilayer PCBs?

Yes. Both fusion bonding and adhesive bonding are supported, depending on performance requirements.

Q2: Is RT/duroid 5880 an RF material?

Yes. It is specifically designed for RF, microwave, and millimeter-wave applications.

Q3: Is RT/duroid 5880 suitable for flexible PCBs?

No. It is rigid. For RF flex PCBs, Rogers FlexWave materials are recommended.

Q4: Is RT/duroid 5880 suitable for aerospace use?

Yes. It meets aerospace-grade requirements including low outgassing and thermal stability.

Q5: RT/duroid 5880 vs FR-4?

Pros:

-

Much lower loss

-

Stable impedance

-

Better thermal and moisture resistance

Cons:

-

Significantly higher cost

-

Specialized processing required

Rogers RT/duroid 5880 delivers unmatched electrical stability and ultra-low loss for mission-critical RF and microwave PCBs. While more expensive than FR-4, it is the preferred choice for applications where performance, reliability, and signal integrity cannot be compromised.

KKPCB specializes in Rogers PCB fabrication, offering:

-

RT/duroid 5880 prototypes & mass production

-

Hybrid Rogers + FR-4 stack-ups

-

Controlled impedance RF PCBs

-

Aerospace & automotive-grade manufacturing