RO4830™ Plus thermoset laminates represent Rogers’ latest advancement in dielectric materials, specifically engineered for cost-sensitive millimeter-wave applications, including 76–81 GHz automotive corner radar sensors.

Electrical Performance Optimized for Automotive Radar

RO4830™ Plus laminates are woven-glass-free thermoset dielectric materials, providing:

-

Stable dielectric constant: ~3.03 at 77 GHz (measured via microstrip differential phase length method).

-

Low insertion loss: Only 1.5 dB/inch for 5 mil laminates, ensuring superior signal integrity in high-frequency radar circuits.

-

Reliable RF performance: Perfect for millimeter-wave automotive radar designs requiring minimal signal attenuation.

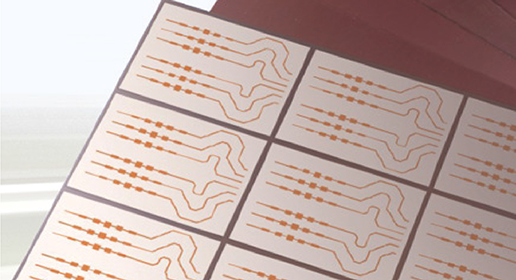

This combination of a low-loss thermoset resin system and very low-profile electrodeposited copper foil ensures high performance for radar PCB applications.

PCB Fabrication Advantages

RO4830™ Plus laminates are designed to serve as the cap layer on FR-4 multilayer boards, commonly used in 76–81 GHz automotive radar PCBs. Key fabrication benefits include:

-

Glass-free structure: Enhances laser drilling performance and CAF (Conductive Anodic Filament) resistance.

-

Compatibility: Works seamlessly with RO4400™ bondply and standard FR-4 epoxy/glass PCB processes.

-

PFAS-free: Environmentally friendly, compliant with modern safety standards.

-

UL-V0 flame rating and lead-free solder compatibility for reliable, safe manufacturing.

Key Features

-

Innovative thermoset resin platform

-

Very low profile (VLP) electrodeposited copper foil

-

PFAS-free, environmentally compliant

Benefits

-

Lower overall PCB manufacturing costs

-

Excellent insertion loss and laser drilling performance

-

High CAF resistance for long-term reliability

-

Consistent within-sheet dielectric constant for design predictability

RO4830™ Plus laminates combine high electrical performance, cost efficiency, and fabrication ease, making them an ideal choice for automotive radar sensor PCB designs operating in the 76–81 GHz range.