// Rigid-flex PCB AssemblyFlex and Rigid-flex PCB Assembly

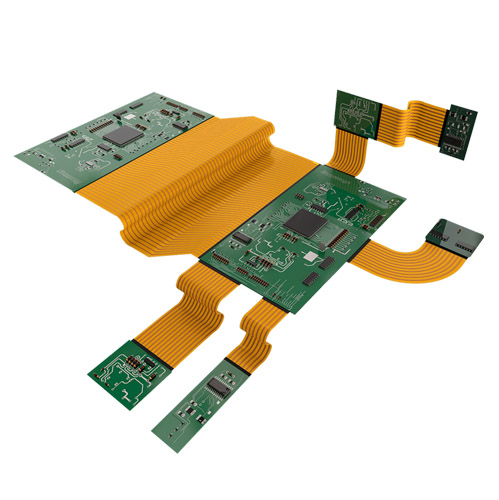

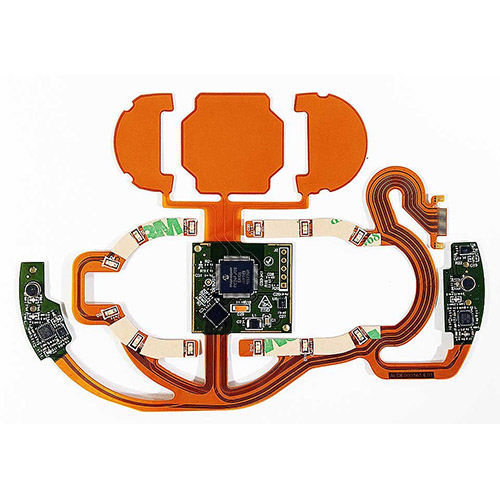

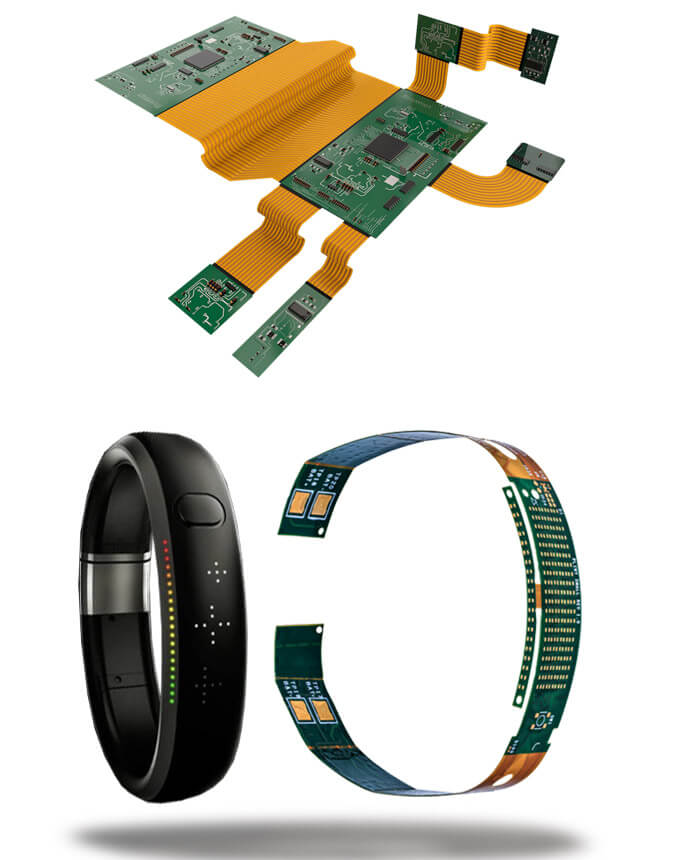

Flexible and rigid-flex PCB technology provides an efficient way to integrate multiple circuit sections, eliminating the need for wires, cables, or connectors by using flexible substrates between rigid sections. Rigid-Flex PCBs are lightweight, thin, compact, and easy to install, making them ideal for high-reliability applications in aerospace, defense, telecommunications, medical devices, and consumer electronics.

Although the fabrication and assembly costs of flexible and rigid-flex PCBs are higher than standard rigid PCBs, their unique advantages—such as space optimization, mechanical durability, and electrical reliability—make them indispensable for advanced electronic designs. The assembly process for flexible and rigid-flex PCBs also differs from standard rigid boards, requiring specialized equipment and expertise.

As a professional flex and rigid-flex PCB manufacturer, KKPCB provides full turnkey solutions, including DFM review, material selection, precision SMT, BGA and microvia assembly, component sourcing, and functional testing. We ensure seamless integration between rigid and flexible sections, delivering high-quality, reliable, ready-to-use PCB assemblies tailored to your requirements.

Looking for a trusted flex and rigid-flex PCB assembly partner? Contact KKPCB today—we’re ready to support your project from design to delivery.

// High-Reliability Turnkey PCB SolutionsHigh-Reliability Rigid-Flex PCBs – Turnkey Assembly

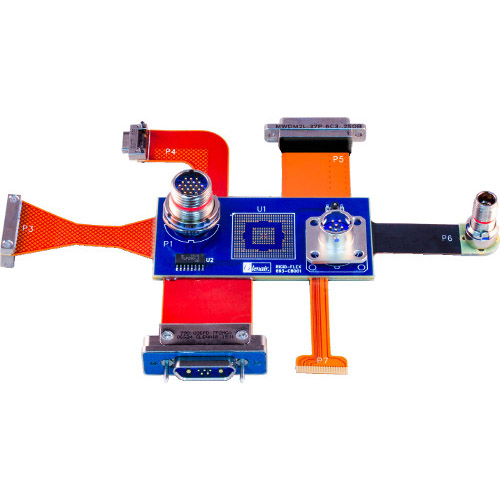

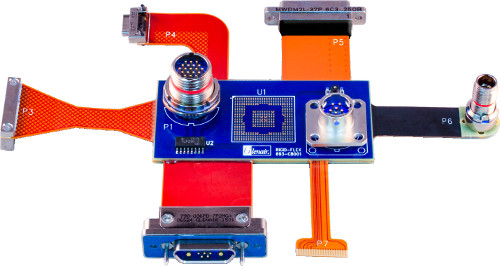

Rigid-Flex PCBs combine the stability of rigid boards with the flexibility of flexible circuits, enabling compact, lightweight, and highly reliable electronic designs. By replacing wires, cables, or connectors with flexible substrates between rigid sections, they reduce interconnect complexity, optimize space, and improve overall device performance. At KKPCB, we provide full turnkey Rigid-Flex PCB assembly services—including DFM analysis, material selection, precision SMT, BGA, and microvia assembly, component sourcing, and functional testing—ensuring seamless integration, superior signal integrity, and mechanical durability. Our assemblies are ideal for aerospace, defense, medical devices, industrial control, telecommunications, and consumer electronics, helping customers simplify complex designs, accelerate product development, and deliver high-quality, ready-to-use solutions.

Rigid-flex PCB Assembly

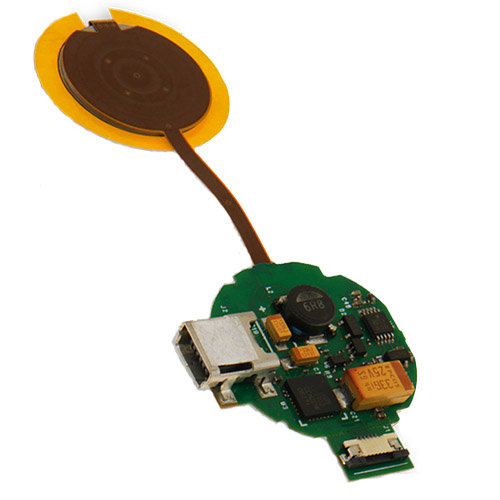

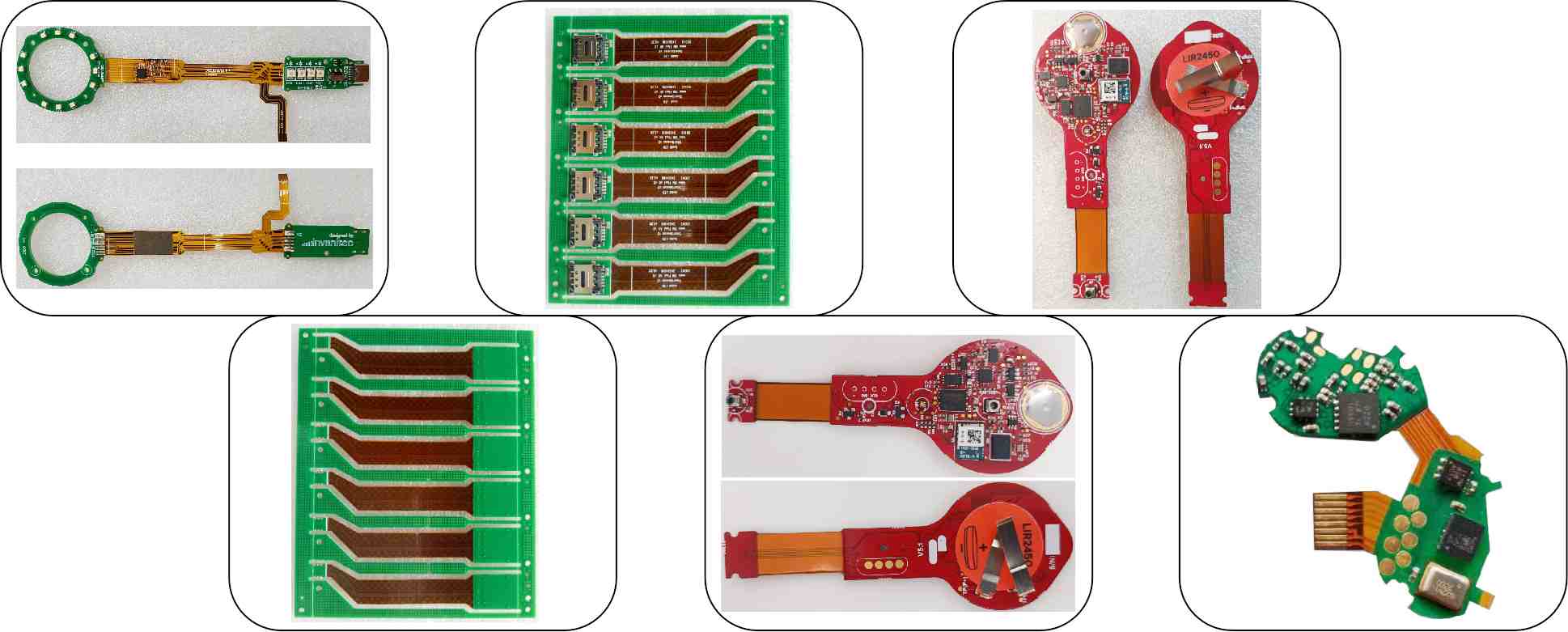

Medical Devices Rigid-flex PCB Assembly

Smart Bracelet Rigid-flex PCB Assembly

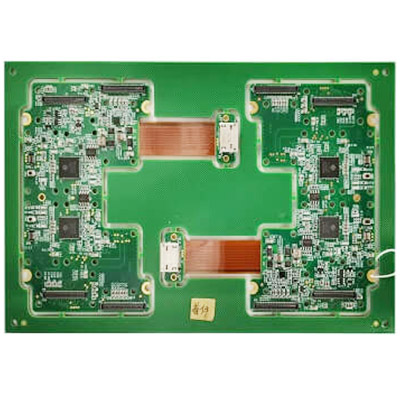

Turnkey Rigid-flex PCB Assembly

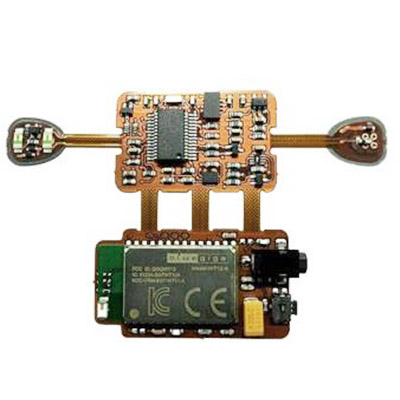

Communications Rigid-flex PCB Assembly

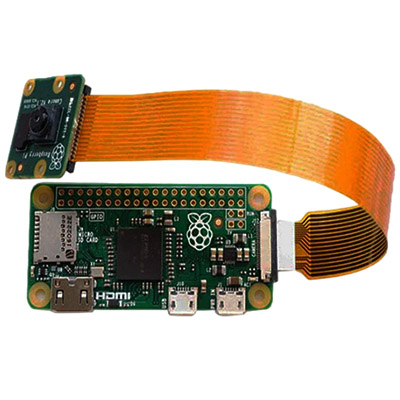

Camera Module Rigid-Flex PCB Assembly

Temperature Sensor Rigid-flex PCB Assembly

Camera Rigid-flex PCB Assembly

Rigid-Flex PCB Assembly manufacturers

// Rigid-flex PCB Assembly ServicesWhy KKPCB for assembly services?

At KKPCB, we are dedicated to maximizing value for our customers by delivering high-quality, cost-effective PCB assembly solutions that never compromise on reliability, performance, or durability. Our comprehensive program management services cover the entire lifecycle of your PCB project—from component procurement and supply chain coordination to full oversight of the assembly process—ensuring a smooth, end-to-end experience and reducing potential bottlenecks or delays.

Our proven expertise spans rigid, flex, and rigid-flex PCB assembly, enabling us to handle complex designs with precision. This expertise ensures higher yields, improved reliability, and reduced defect rates, directly translating into cost savings and enhanced product performance.

Beyond assembly, KKPCB offers a highly skilled Test Engineering team capable of performing comprehensive electrical and functional testing tailored to your unique requirements. Our engineers have developed advanced automated custom test equipment, providing the high throughput necessary for large-scale production programs while maintaining exceptional accuracy, repeatability, and quality assurance.

By partnering with KKPCB, customers benefit from:

-

End-to-end turnkey assembly solutions that simplify project management

-

Optimized material usage and panelization for cost-effective production

-

High-yield, reliable assemblies across rigid, flex, and rigid-flex designs

-

Comprehensive testing capabilities to ensure performance and quality

-

Expertise in complex and large-scale programs, accelerating time-to-market

With decades of experience across industries including consumer electronics, industrial control, medical devices, telecommunications, and aerospace, KKPCB is a trusted partner for companies seeking scalable, high-quality, and cost-efficient PCB assembly solutions that drive innovation and deliver measurable business value.

Our Experience In Flexible PCB Assembly

Positive Evaluation

KKPCB Limited remains one of the best around when it comes to rendering the best of flexible PCB assembly services. We have been able to handle different types of projects in the past. Do you want to know the best part? Such is the fact that we have earned numerous positive reviews from customers. Over the years, we have proven to have great understanding about flexible printed circuits. For instance, they can show great dynamism when it comes to folding and curling.

Industries served

They can easily expand into 3D spaces. When it comes to freedom in terms of circuit and mechanical designs, flexible PCB is the best option you can explore. With this, it is very possible for tracing to be carried out on various surfaces. This doesn’t only reduce machine work. It can also ensure human errors are decreased to their barest minimum. Some fields where you will find these printed circuit boards are military, aerospace, healthcare devices, instruments, computers and communicators.

We Are Experts

In order to get the best from flexible PCB assembly, it is important that a trusted and proven company handles such process. There is no need being worried though since such is the reason why we are existing. This is because we have the best hands that can help in ensuring the project is handled according to your specifications and expectations. Our experts are the best around. They have very vast level of knowledge and understanding about what flexible PCB assembly entails. Therefore, you can be rest assured that they will deliver without any compromise.

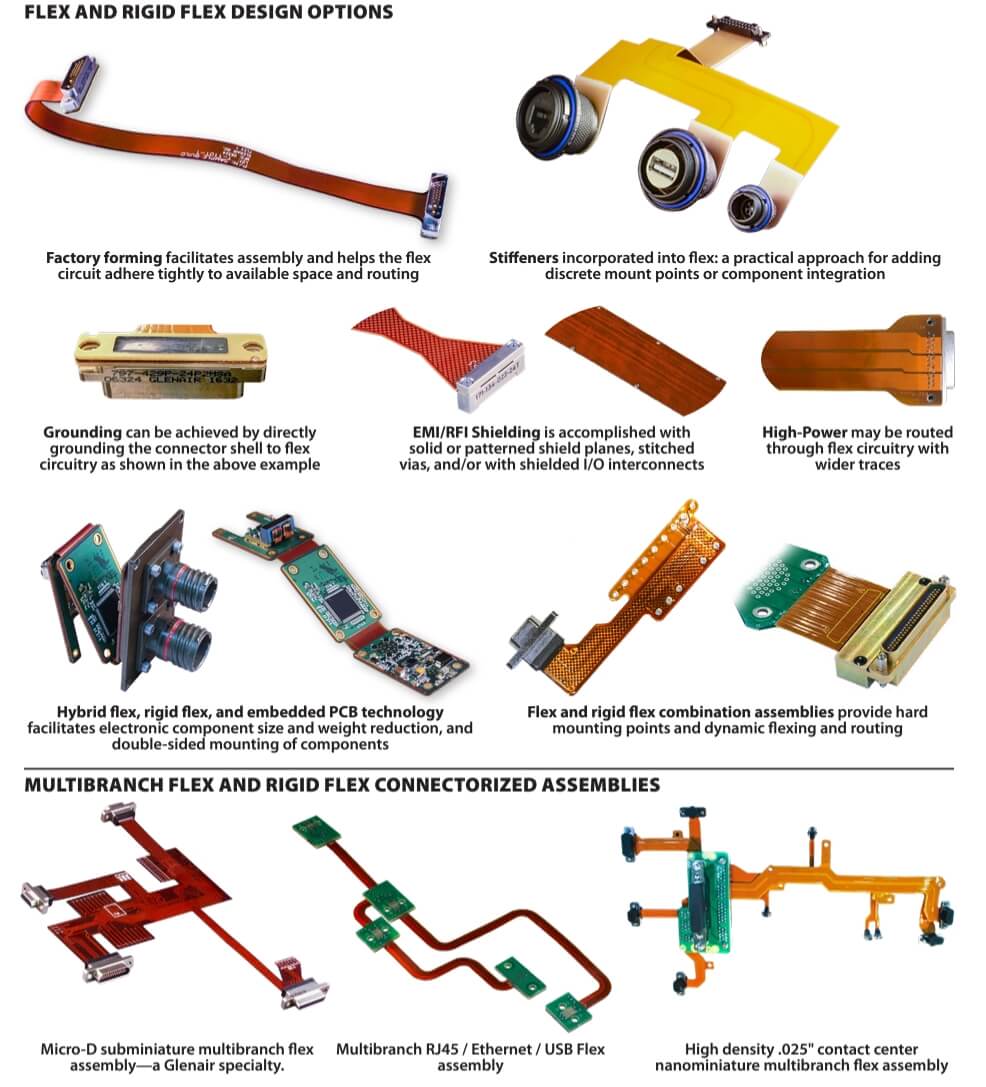

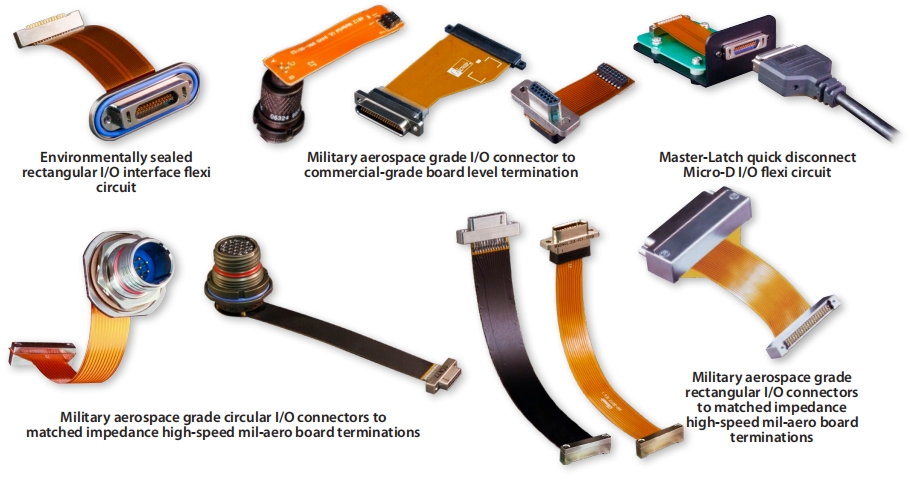

Flex Circuit Assemblies: Turnkey, Connectorized PCB Solutions

Flex circuits — metallic layers of traces, usually copper, bonded to a dielectric layer, like polyimide — are used to interconnect embedded electronic packages, displays, backplanes, and other PCB components. Flex and rigid-flex circuits are frequently superior to conventional wiring as they can be easily routed in three dimensions, are lighter and smaller than discrete wires, and offer virtually unlimited flex cycles in articulated applications. Flex and rigid-flex circuits are commonly deployed within avionic LRUs and other complex electronic systems, as well as between articulating components, such as disk drive, robotic arms, and other electro-mechanical devices.

Compared with conventional wiring, compact flexible printed circuit assemblies reduce system complexity and assembly time as well as enhance reliability. Due to their low mass and high circuit density, flex circuit assemblies are less susceptible to impact and vibration damage than conventional wire harness assemblies, making them an ideal choice in satellite applications such as articulated solar arrays, sensors, and antenna.

Replacing Complicated Wire Bundle Assemblies with High-Density Flex Circuit Assemblies Assures Faster, Error-Free LRU Assembly

- Single-sided, double-sided, and multilayer flex circuitry

- Flex, rigid flex, and PCBA board assemblies

- Through-hole and surface-mount connector terminations

- Turnkey catalog jumper assemblies

- Fairway-Flex long-length flex circuit assemblies

// Frequently Asked Questions (FAQ)Rigid-flex PCB assembly (FAQ)

Rigid-flex circuit boards offer a versatile and efficient solution for complex electronic designs that require both rigidity and flexibility. By integrating rigid and flexible elements into a single board, rigid-flex designs address space constraints, reduce assembly complexity, and enhance durability. These boards are used in a wide range of applications, including aerospace, medical devices, consumer electronics, and automotive systems, where their unique characteristics provide significant benefits.

Rigid-flex boards are ideal for space-constrained applications because they integrate both rigid and flexible sections into a single, compact design, eliminating the need for separate connectors and cables. Their ability to conform to complex shapes and fit into confined spaces optimizes available space and reduces assembly complexity. Additionally, their flexible sections can absorb mechanical stress and vibrations, enhancing reliability and durability in compact environments. These features make rigid-flex PCBs well-suited for consumer electronics, medical devices, aerospace, and other applications where efficient space utilization is critical.

Yes, you can count on us for quick turnaround times for rigid-flex printed circuit boards. We understand the importance of timely delivery in prototyping and production. Our streamlined processes and efficient manufacturing capabilities enable us to provide rapid responses and meet tight deadlines without compromising on quality. If you have specific time constraints, please let us know, and we’ll work to accommodate your needs and ensure that your rigid-flex PCBs are delivered on time.

Yes, we undertake rigid-flex PCB repair and rework. Our services include troubleshooting, repairing damaged or defective areas, and reworking components on rigid-flex boards. We use specialized techniques and equipment to ensure that the integrity of both the rigid and flexible sections is maintained during the repair or rework process. If you have specific issues with your rigid-flex PCBs, please provide details, and we’ll work to resolve them efficiently and effectively.

Our testing protocols for rigid-flex PCB manufacturing include comprehensive visual inspections, electrical testing for continuity and functionality, and electrical performance assessments such as signal and power integrity. We also conduct mechanical tests, including flexibility and thermal cycling, to ensure durability under stress. Automated Optical Inspection (AOI) and In-Circuit Testing (ICT) are used for detecting defects and verifying component placement. Additionally, we verify material quality and construction integrity, perform environmental testing, and ensure compliance with industry standards. These rigorous tests ensure that our rigid-flex PCBs meet high quality and performance standards.

Our customer service efficiency is a top priority. We focus on providing prompt and effective support throughout the entire process, from initial inquiries to post-production assistance. Our team is dedicated to addressing your questions, resolving issues, and ensuring that your needs are met quickly and efficiently. We offer clear communication, timely updates, and personalized support to ensure a smooth and satisfactory experience. If you have any specific concerns or requirements, please feel free to reach out, and we will be happy to assist you.

To get a quote for rigid-flex PCBs from KKPCB, provide detailed specifications including design files, quantity, and any assembly requirements. You can submit your request via our online form or email. Our team will review your information and provide an initial quote, potentially reaching out for clarifications. After reviewing and confirming the quote, we will proceed with production and offer ongoing support throughout the process. This ensures a smooth and efficient quoting and manufacturing experience.