//Box Build Assembly ServicesSystem Box Build Assembly and Integration Services

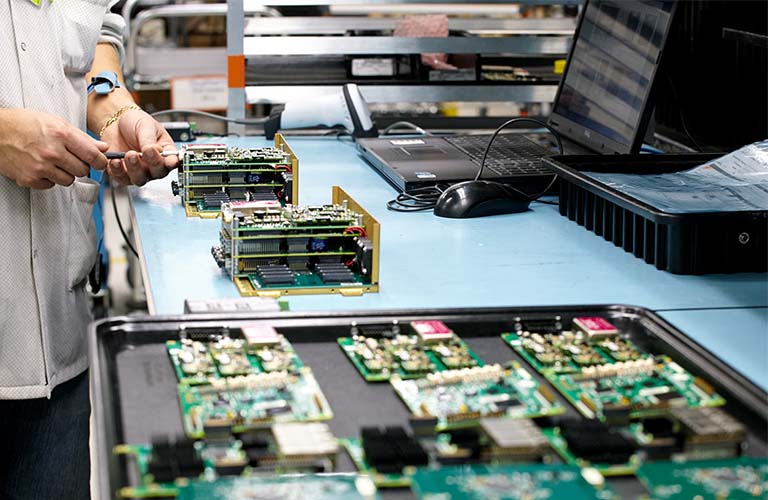

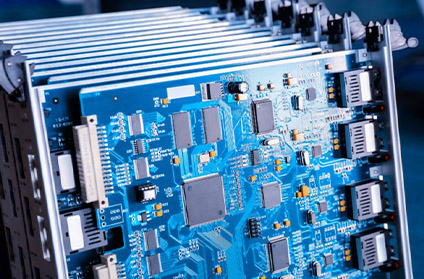

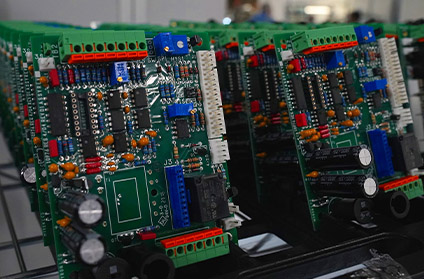

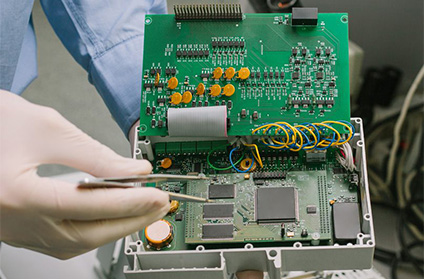

- Assembly & testing of printed circuit boards

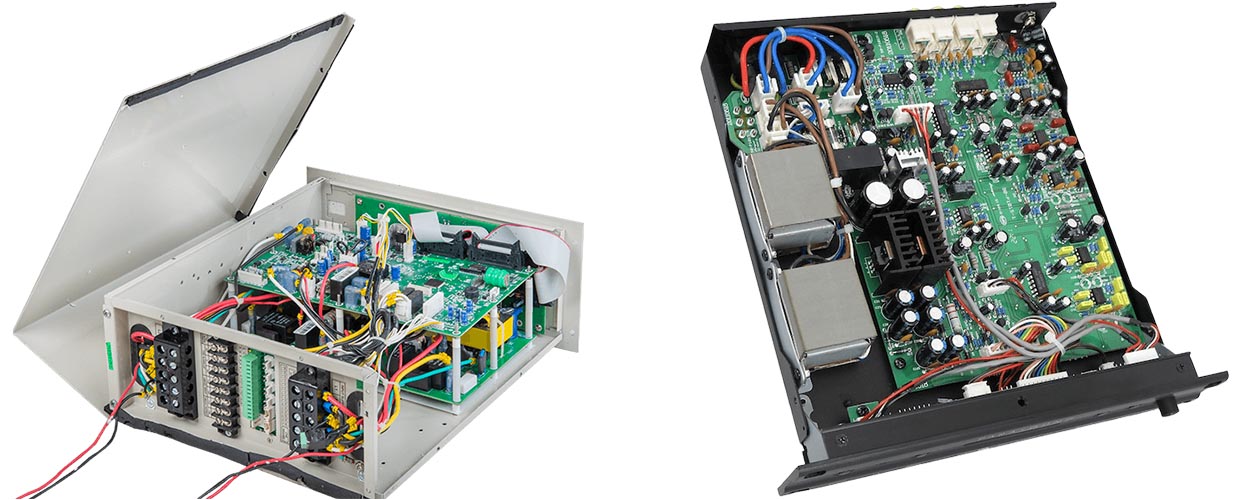

- Integration of board assemblies into a sub-rack or housing

- Assembly of power supplies, cable assemblies, thermal management units

- Addition of line cards, modules & other sub-assemblies

- Product software configuration

- Serialization and product tracking

- Full cabinet integration – configured to your specification

- Final test to specification

- Direct shipment of final packaged units to end customers

- Fabrication and integration of wire harnesses

- PCB layout service

// Turnkey PCB Box Build AssemblyReliable PCB Box Build Assembly Manufacturer

KKPCB provides comprehensive PCB Box Build Assembly services, delivering complete system integration from PCBA to fully finished products. Our capabilities cover every stage of the process, including PCB assembly, mechanical enclosure installation, cable and wire harnessing, sub-module integration, functional testing, and final packaging. With advanced automated lines, skilled technicians, and a strict quality management system, we ensure precision, reliability, and consistency in every build. Serving industries such as industrial control, telecommunications, automotive, medical electronics, smart devices, and new energy, KKPCB supports both low-volume prototypes and large-scale production. By combining electronic, mechanical, and system-level expertise, we help our customers accelerate product launches while maintaining high quality and cost efficiency — building not just boards, but complete products ready for the market.

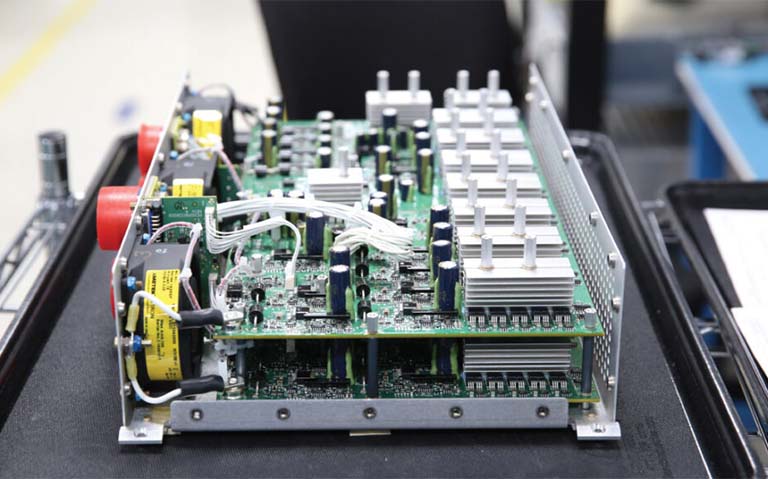

Automotive Traction Control PCB Assembly

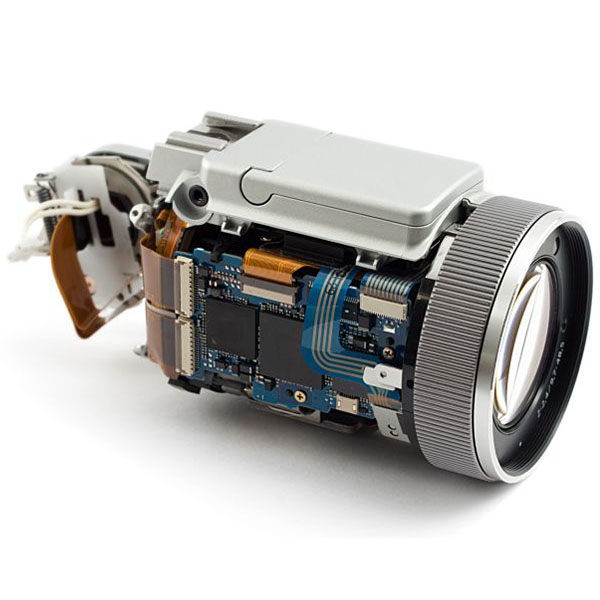

Camera Box Build Assembly

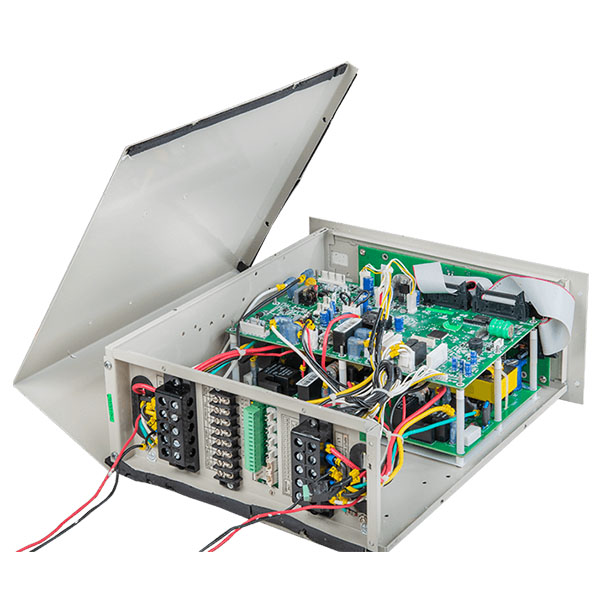

Box Build Assembly Services

Industrial Control Equipment Box Build Assembly

Energy Storage Module Inverter PCB Assembly

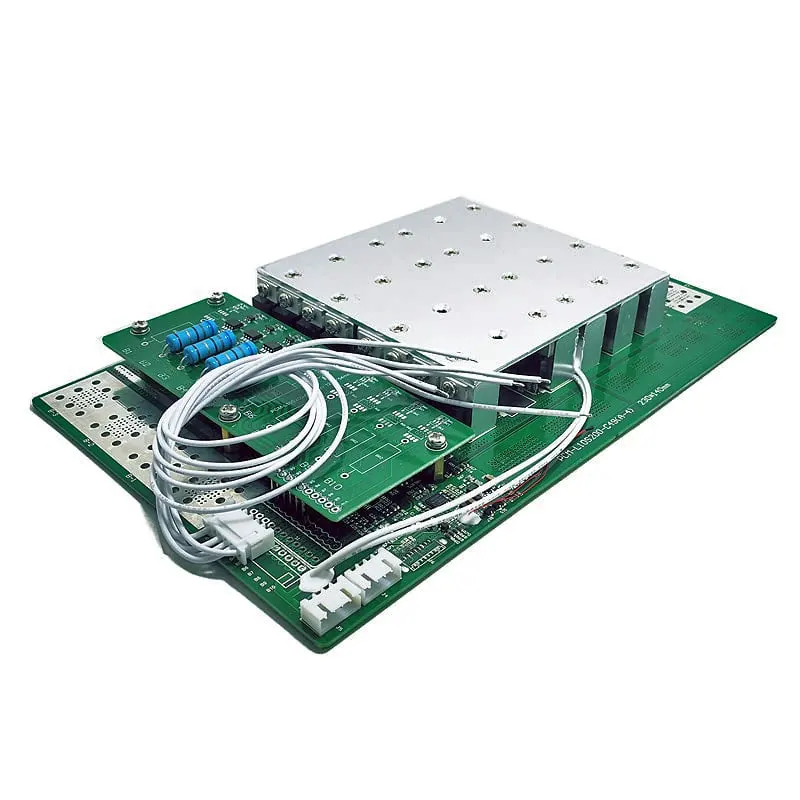

Energy Storage Protection Circuit Module PCBA

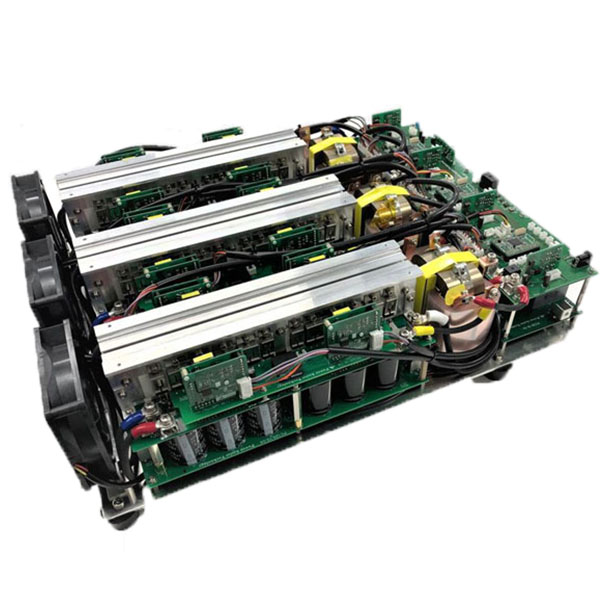

3-Phase 50kW Bidirectional Inverter Utilizing

60 kW Interleaved LLC Converter Assembly

Set-Top Boxes PCB Assembly

// Box Build Assembly ServicesAll-in-One Box Build Assembly Services

// Box Build Assembly ServicesWhy Choose KKPCB?

Box Build Assembly Testing

KKPCB capabilities also extend into robust quality assurance and testing departments. Our skilled technicians and expert engineers understand the project requirements and deliver a product specific to them. Our robust testing strategies are crafted to predict errors early on in the final assembly process to mitigate any unnecessary risks for the end-users. We have also designed final assembly tests to ensure product quality, functionality, and long-term reliability.

We have a reliable in-house quality assurance system for complete testing of the box build. Our test engineering team creates a feasible test plan for validating your product. We even provide assistance in the early design phases as well by performing design reviews, validation, netlist verification, end-of-life (EOL) parts review, Design for Manufacturability (DFM) checks, Design for Testing (DFT), and even cost-optimized Bill of Materials (BOM) generation.

Our PCB Box Build Test Capabilities include:

- Custom Test Fixtures and Test Beds

- Flying Probe and ICT Test

- Dielectric Testing

- X-Ray Inspection

- Device programming (JTAG, BDM, etc.)

- Device and Assembly Serialization

- RF Test

- Systems Test

- Full Functional Test

- Hi-Pot and High Voltage Test

- Automated Optical Inspection (AOI)

- Boundary Scans

- Voltage and Current Test

- Custom Labels

- 3D printing

Box Build Assembly Capabilities

KKPCB is specialized in providing next-level customer products with electronic box build assembly capabilities. The cabinetry, backplanes, and cables are all assembled in-house and we also offer many value-added services like conformal coating, perylene coating, and encapsulations. We are also capable of providing high-end custom solutions for rapid prototyping to high-volume production.

Our Box Build Assembly capabilities are

- High-level Integration and assembly

- Custom packaging and labeling

- Environmental Testing

- Cable and Wiring Harness Assembly

Multifaceted PCB Box Build Assembly Services forCutting-Edge Industries

Box Build Assembly services are at the heart of many industries and WWPCB has been a guiding light for so many industrial sectors for nearly 4 decades. We have the expertise to keep your project going with our specialized PCB assembly services, reliable testing, dedicated support, and certified workmanship. With our capabilities, we have served a wide range of industries Here’s a list of industries we serve with high-reliability applications.

KKPCB Box Build Assembly solutions are used in aerospace, communications, test and measurement, industrial control, aerospace, medical electronics, dentistry, communications equipment, renewable energy, Internet of Things, etc.

// Frequently Asked Questions (FAQ)PCB Box Build Assembly (FAQ)

Box build assembly involves integrating and assembling various components, including PCBs, into a finished product or enclosure. This process includes not only mounting the PCBs but also assembling the enclosure, performing functional and quality tests, and adding any custom features. The goal is to ensure that the complete system is fully integrated, functional, and ready for use or shipment.

To get started with box build assembly, first define your project requirements, including components and functionality. Develop designs and prototypes to validate the assembly. Source all necessary parts, create a detailed assembly plan, and choose a reliable manufacturer experienced in box build assembly. The manufacturer will handle the integration of components into the enclosure, conduct testing, and ensure quality control. Finally, finalize the assembly and arrange for delivery or distribution of the completed product.

Once you chose a CM for your PCB Box Build project, then you need to provide assembly drawings, electrical schema, bill of materials, wire lists, test specifications, etc. A CM can also start the box build with just the Bill of materials and electrical schematic but may miss out on crucial information. And it may result in lots of calls and meetings, so it is better to provide them as much information as possible for a successful build.

A box build contains wire harnesses, point-to-point wiring, PCBs, and the mechanical structure of the entire box. One needs to club all these together and give a proper structure to these pieces. Cut, strip, and label the individual wire ends, build & test all device cables and wire harnesses, and start the assembly process from the bottom.

We inspect every aspect of the process and focus on the crucial areas of the product assembly. We test the box build and record the results and observations.

hoose KKPCB for PCB box build assembly because we offer comprehensive solutions with high-quality standards, including expert integration of PCBs and other components into custom enclosures. Our services feature precise assembly, rigorous testing, and robust quality control to ensure your product meets all specifications. With a focus on efficient processes and excellent customer support, we provide reliable and timely results, making us a trusted partner for your box build assembly needs.

We have a dedicated in-house staff and equipment plus production space to perform your bob build assembly. We try to keep your overhead costs lower and provide high-quality services and hence we deploy none but the best on your product.

Of course. We do implement the PCB Box Build assembly services in strict compliance with the ISO and IPC standards. We follow an uncompromising approach when it comes to quality assurance and hence build our products by meeting the laid-out industry standards.

We follow the standard PCB Box Build process wherein we design and engineer different sub-level product assembly, install different sub-assemblies and components, load the software, and configure the product. Finally, labeling and packaging would be done before we perform drop shipping. Of course, the complexity of each phase differs from one assembly to another.