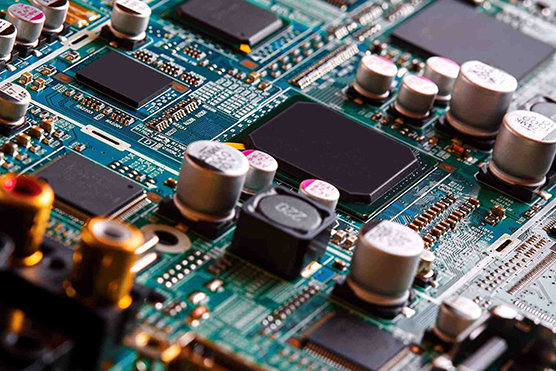

1. Introduction to Power Supply PCB Design

Power supplies exist in a wide range of topologies, voltage levels, power ratings, and safety requirements, which makes power supply PCB design one of the most challenging areas in electronic engineering.

Although the design choices are extensive, successful power supply PCBs always follow a set of fundamental layout and assembly principles. Ignoring these principles often leads to:

-

Poor efficiency

-

Excessive EMI

-

Thermal issues

-

Power instability

At KKPCB, we specialize in manufacturing high-current, high-reliability power supply PCBs, supporting both linear and switching power supply designs.

2. Basic Functions and Types of Power Supplies

A power supply performs three core functions:

-

Receives energy at a specific voltage and current

-

Processes and converts the energy

-

Outputs regulated power suitable for connected circuits

2.1 AC and DC Power Supplies

Power supplies are generally classified into:

-

AC power supplies

-

DC power supplies

Beyond generators, power supplies can be further divided into:

-

Inverters – Convert DC input to AC output

-

Converters – Convert AC or DC input to DC output

Both inverter and converter power supplies may provide:

-

Single or multiple DC outputs

-

AC outputs

-

Mixed fixed and variable voltages

-

Current limiting and protection functions

3. Power Supply Topologies: Linear vs Switching

The power supply topology determines how input voltage is transformed into output voltage.

3.1 Linear Power Supplies

-

Simple structure

-

Low noise

-

Poor efficiency

-

Significant heat dissipation

3.2 Switching Power Supplies (SMPS)

-

High efficiency

-

Compact size

-

Higher noise and EMI

-

Requires careful PCB layout

Although switching power supplies dominate modern electronics due to efficiency, they place much higher demands on PCB layout, grounding, and EMI control.

4. Functional Circuit Modules in Power Supply PCBs

In addition to basic conversion circuitry, power supply PCBs often integrate:

-

Rectifier circuits

-

Power factor correction (PFC) modules

-

Input EMI filtering

-

Control and feedback circuits

-

Output filtering circuits

-

Overvoltage and overcurrent protection

Each module introduces different signal levels and current characteristics, making PCB partitioning and routing discipline critical.

5. Key Characteristics of Power Supply PCB Design

Although linear and switching power supplies operate differently, many PCB design rules apply to both.

5.1 Limitations of Autorouting

While CAD tools assist PCB design, autorouters are poorly suited for power supply PCBs, because they:

-

Ignore current magnitude

-

Ignore loop area optimization

-

Do not account for EMI-sensitive paths

Power supply designers must manually control routing, especially for high-current paths.

6. Current Loops and Power Supply Circuitry

6.1 Linear Power Supply Current Loops

-

Input source loop

-

Output load loop

6.2 Switching Power Supply Current Loops

In addition to the above:

-

High-current switch loop

-

High-current output rectifier loop

These loops carry pulsating DC currents with fast edges, which are the primary sources of:

-

Conducted EMI

-

Radiated EMI

6.3 Layout Principles for Current Loops

-

Keep loops as small as possible

-

Use short and wide traces

-

Isolate different current paths

Reducing loop area minimizes AC energy leakage and EMI emissions.

7. Trace Width, Inductance, and Thermal Considerations

Trace width directly affects:

-

Resistance

-

Inductance

-

Voltage drop

-

Heat dissipation

Narrow traces:

-

Increase inductance and resistance

-

Increase voltage ripple

-

Generate RF radiation

Wide copper traces:

-

Reduce EMI

-

Improve efficiency

-

Enhance thermal performance

For high-power designs, KKPCB recommends:

-

Wider traces

-

Heavy copper PCB options

-

Copper pours or planes

8. Grounding Strategy in Power Supply PCBs

Proper grounding is essential for power stability and noise suppression.

8.1 Separate Ground Domains

Designers must separate:

-

High-current input ground

-

High-current output ground

-

Low-current control ground

These grounds typically merge at a single point near the input source to avoid ground loops.

8.2 Mixed-Signal Power Supply Boards

When analog, digital, and power circuits coexist:

-

Route sections separately

-

Use short, wide connections to sense resistors

-

Apply Kelvin connections when possible

8.3 Ground Planes and EMI Control

High-current traces should be:

-

Shielded with ground planes

-

Routed over continuous reference planes

Large ground planes act as electrostatic shields, absorbing EMI and dissipating it as heat.

9. Parallel Capacitor Design for Output Filtering

Output filter capacitors are affected by:

-

Equivalent Series Resistance (ESR)

-

Equivalent Series Inductance (ESL)

High ESR and ESL cause:

-

Output ripple

-

Capacitor heating

-

Reduced efficiency

Best Practices:

-

Use multiple capacitors in parallel

-

Select identical capacitance values

-

Maintain symmetrical PCB layout

-

Keep interconnecting traces short and wide

This ensures even current distribution and minimizes parasitic impedance, preventing high-frequency current isolation.

10. KKPCB Power Supply PCB Manufacturing Advantages

KKPCB supports power supply PCB projects with:

-

High-current PCB manufacturing

-

Heavy copper and thick copper PCBs

-

Multilayer power supply PCBs

-

DFM and EMI-aware layout support

We help customers achieve:

-

Higher efficiency

-

Lower EMI

-

Better thermal performance

-

Long-term reliability

Power supply PCB design and assembly require a deep understanding of:

-

Power topology

-

Current loop behavior

-

Grounding strategy

-

EMI control

-

Thermal management

A well-designed PCB is just as important as the schematic itself.

Partner with KKPCB to ensure your power supply PCBs meet the highest standards of performance, safety, and manufacturability.