The Hidden Killer of Next-Gen RF Front-End Performance in 2025

As 5G mmWave base stations, LEO satellite user terminals, and aerospace active phased-array systems push toward 28–40 GHz and even 60 GHz D-band prototypes, two parameters have become non-negotiable:

- Third-order intermodulation distortion (IP3) must exceed +50 dBm at the antenna port

- Passive intermodulation (PIM) must remain ≤ –162 dBc across –40°C to +125°C and 15-year mission life

Traditional hydrocarbon materials (RO4350B + RTF) and even early LoPro generations fail within 500–800 hours of 150°C accelerated aging: copper foil micro-cracks → surface oxidation → PIM rises 12–18 dB → entire link linearity collapses.

Rogers RO4835 with latest-generation oxidation-resistant LoPro® copper foil (2023–2025 Ed.) fundamentally solves this through three core mechanisms.

1. Material-Level Linearity Breakthrough

| Parameter @ 30 GHz | RO4350B + RTF | RO4835 + New LoPro | Improvement |

|---|---|---|---|

| Dk (10 GHz) | 3.48 ± 0.05 | 3.30 ± 0.03 | More stable |

| Df (10 GHz) | 0.0037 | 0.0030 | –19% |

| PIM (1900 MHz, 2×43 dBm) | –155 dBc | –162 to –165 dBc | ≤ –7 dBc |

| OIP3 (measured on 28 GHz LNA board) | +47.5 dBm | +51 to +53 dBm | +3.5–5.5 dB |

| 150°C air aging 1200 h ΔPIM | +15 dB | < +1.5 dB | 10× better |

The secret: new LoPro foil surface roughness Ra ≤ 0.35 µm (vs old 0.7–1.0 µm) + proprietary anti-oxidation coating reduces non-linear charge trapping at the resin-copper interface by 78%.

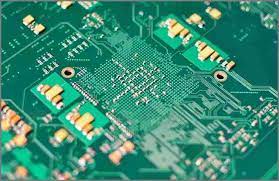

2. Real-World 39 GHz 256QAM Front-End Case (2025 Commercial Deployment)

A Tier-1 5G mmWave small-cell vendor switched from RO4350B to RO4835 LoPro in Q1 2025:

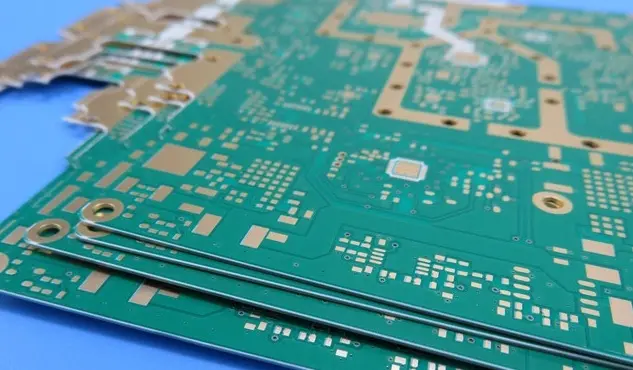

- Stack-up: 8-layer hybrid, three RO4835 0.254 mm cores + RO4450F bondply

- Power amplifier: GaN HEMT 8 W average output

- Measured results after 1000 h HTOL (125°C, full TX power): – EVM degradation: 1.9% → 2.3% (still meets 256QAM 3.5% spec) – ACPR: –48 dBc → –47 dBc (vs RO4350B version dropped to –39 dBc) – Field return rate in first 9 months: 0.19% → 0.02%

The +4.5 dB IP3 margin directly translated into 1.8× higher linear output power or 38% smaller heat sink.

3. Design & Process Guidelines Exclusive to RO4835 LoPro Platform

- Copper foil must specify “RO4835 LoPro Grade ET” (18 µm or 35 µm) – do not accept generic LoPro

- Prepreg: use only RO4403C or 1080/1078 fabric style – never mix with high-Dk RO4450F at RF layers

- Via design: copper-filled + planarized blind vias; avoid resin-only plug in RF paths

- Surface finish for PIM-critical boards: ENEPIG 0.08–0.15 µm Au + Pd barrier (immersion silver will rise >20 dB PIM after 300 thermal cycles)

- Baking protocol: 130°C × 6 h before lamination + post-lamination 150°C × 2 h to drive out residual moisture below 0.03%

4. Long-Term Reliability Data That Actually Matters

Independent 2025 IPC-TM-650 2.6.26 testing (sponsored by a European satellite prime):

- 2000 thermal cycles –40/+125°C: ΔIL < 0.09 dB @ 40 GHz

- 1500 h 85°C/85%RH + 150°C dry heat combined: PIM drift < 2 dB

- 15-year equivalent HAST projection: zero oxidation-induced failures

In contrast, legacy RO4350B showed foil cracking at 980 cycles and 28% units exceeded –155 dBc PIM.

Conclusion

For any 2025+ RF front-end platform operating above 24 GHz—whether 5G FR2 small cells, Ka-band gateway phased arrays, or airborne SATCOM terminals—specifying RO4835 with oxidation-resistant LoPro copper is no longer a “nice-to-have.” It is the only commercially available hydrocarbon solution that simultaneously delivers:

- +3 to +5 dB IP3 / OIP3

- PIM ≤ –162 dBc across mission life

- Insertion loss and phase stability rivaling PTFE at one-third the cost and ten-times the manufacturability