Engineering Stability in Extreme Aerospace Environments

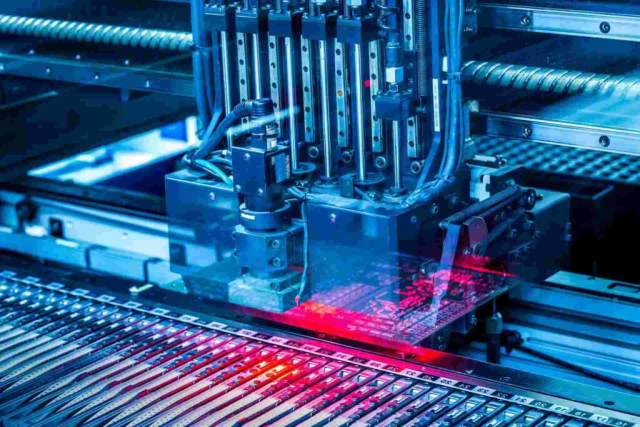

Aerospace and radar systems operate under extreme conditions—rapid temperature gradients, vibration, and continuous high-power RF transmission.

Under these stresses, PCB dielectric and thermal stability determine the long-term performance of radar front-ends, phased arrays, and high-power amplifiers.

Rogers Duroid 6010, with its high dielectric constant (Dk = 10.2 ± 0.25) and low dissipation factor (Df = 0.0023 @ 10 GHz), is specifically engineered for miniaturized, thermally robust RF modules. Its ceramic-filled PTFE composition delivers excellent dimensional control, low Z-axis expansion (24 ppm/°C), and consistent impedance over wide temperature spans.

KKPCB transforms these material advantages into production-level thermal reliability through a controlled lamination and validation workflow tailored for aerospace-grade PCBs.

Why Duroid 6010 Excels in High-Thermal-Stress Applications

| Property | Value | Reliability Advantage |

|---|---|---|

| Dielectric Constant (Dk) | 10.2 ± 0.25 | Enables compact high-frequency circuits |

| Dissipation Factor (Df) | 0.0023 @ 10 GHz | Reduces insertion loss under power load |

| Thermal Conductivity | 0.66 W/m·K | Efficient heat spreading in high-power RF |

| Z-Axis CTE | 24 ppm/°C | Maintains via integrity through thermal cycling |

| Moisture Absorption | < 0.1 % | Stable dielectric under humidity exposure |

These properties make Duroid 6010 ideal for aerospace radar modules, satellite communication payloads, and long-duration mission electronics where signal drift or dielectric variation is unacceptable.

KKPCB’s Thermal Reliability Framework

To ensure long-term operational endurance, KKPCB applies a comprehensive process that bridges thermal simulation, material matching, and accelerated testing:

1. Material Pre-Treatment and Lamination Control

-

Duroid 6010 sheets pre-baked at 120 °C / 4 h for moisture removal.

-

Vacuum-assisted lamination at 180 °C / 60 min / 200 psi.

-

Balanced cooling gradient to limit warpage < 0.1 mm per 250 mm panel.

2.Thermal Stress Simulation and Profiling

-

Finite Element Modeling (FEM) to simulate expansion mismatch between Duroid and copper layers.

-

CTE-balanced stackups designed for hybrid configurations (Duroid + low-Dk PTFE).

3.Reliability Validation per IPC-TM-650

-

Thermal cycling: –55 °C ↔ +150 °C / 1000 cycles.

-

Humidity exposure: 85 °C / 85 % RH / 1000 h.

-

RF performance monitored using inline VNA up to 110 GHz.

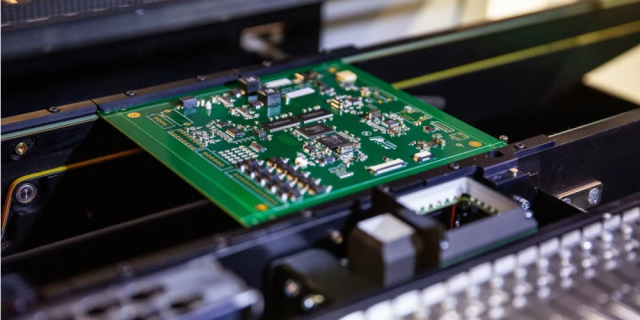

Case Study — X-Band Radar Transceiver Module for Aerospace Surveillance

Client: Asian aerospace electronics OEM

Objective: Develop a lightweight radar transceiver board with stable impedance and phase under wide thermal gradients.

Design Parameters:

-

Frequency: 9–10 GHz X-band

-

Insertion Loss: ≤ 0.3 dB/inch

-

Impedance Tolerance: ± 5 %

-

Thermal Cycling: –55 °C ↔ +150 °C

KKPCB Engineering Implementation:

-

Material: Duroid 6010 core (0.254 mm) + PTFE bonding film.

-

Hybrid stackup: balanced CTE using symmetrical Duroid + copper foils.

-

Controlled lamination profile to minimize microvoid formation.

-

Inline S-parameter verification after each lamination cycle.

Results:

| Test Type | Before Optimization | After KKPCB Process |

|---|---|---|

| Insertion Loss (S21) | 0.34 dB/inch | 0.27 dB/inch |

| Impedance Variation | ± 8 % | ± 3.5 % |

| Delamination Rate | 4.2 % | < 0.4 % |

| Phase Drift (–55 → +150 °C) | 2.8° | 0.9° |

Outcome:

After 1000 thermal cycles, no delamination or microvia fatigue was observed. The radar module successfully passed RTCA DO-160 thermal endurance qualification.

Engineering Insights — Managing Dielectric Stability at High Dk

While Duroid 6010’s high-Dk value enables compact circuits, it also magnifies dielectric drift sensitivity during heating and cooling.

KKPCB engineers address this through:

-

Low-flow bonding films for consistent resin distribution.

-

Tightly matched copper roughness (Ra < 0.8 µm) to prevent localized heating.

-

Phase-stabilized conductor geometry validated with 3D EM simulation.

This engineering approach ensures minimal S-parameter drift even during extended aerospace missions or radar operations.

Extended Reliability Testing for Defense and Space Systems

KKPCB validates thermal and dielectric reliability through multiple endurance protocols:

| Test Category | Condition | Result |

|---|---|---|

| Thermal Shock | –55 °C ↔ +125 °C / 500 cycles | No via crack or impedance drift |

| Power Aging | 125 °C / 1000 h RF load | Df variation < 0.0002 |

| Vibration (MIL-STD-810G) | 20–2000 Hz | No delamination |

| Humidity Resistance | 85 °C / 85 % RH / 1000 h | Moisture absorption < 0.1 % |

These tests confirm Duroid 6010’s structural and dielectric resilience under mechanical, thermal, and environmental stress.

KKPCB Quality & Traceability Framework

-

Material Batch Verification: Dk/Df measurement under controlled humidity.

-

3D Lamination Simulation: Optimized for multi-material stackups.

-

Inline RF Validation: VNA and TDR testing up to 110 GHz.

-

Accelerated Aging: Thermal and power endurance tests per IPC standards.

-

Failure Mode Analysis: Cross-section and delamination inspection for continuous improvement.

This ensures that every aerospace or radar PCB from KKPCB is traceable, verifiable, and production-stable.

Conclusion — Proven Reliability for Aerospace and Defense

Duroid 6010 PCBs combine high dielectric precision, superior thermal endurance, and compact RF performance, making them a foundation for next-generation radar and aerospace platforms.

Through KKPCB’s engineered process control and reliability validation, every board delivers consistent signal integrity, mechanical stability, and thermal reliability across mission-critical environments.

-

Full thermal reliability & humidity endurance validation.

-

Qualification reports for aerospace and defense compliance.

Contact KKPCB Engineering Support to evaluate your Duroid 6010 PCB design or schedule a reliability test consultation for aerospace radar applications.