Achieving High-Frequency Reliability and Efficient Heat Dissipation Through KKPCB’s Hybrid Lamination Platform

From Material Performance to System-Level Efficiency

In industrial mmWave transceiver modules operating from 28 to 81 GHz, engineers face a dual challenge: maintaining signal integrity across multilayer stackups while managing localized power density and heat accumulation.

Traditional FR-4 or mid-grade PTFE composites often struggle to balance dimensional stability and dielectric uniformity at such high frequencies—resulting in phase drift, impedance mismatch, and uneven RF gain.

Duroid 6002 PCB material, featuring a Dk of 2.94 ± 0.04 and Df of 0.0012 @ 10 GHz, offers exceptional dimensional accuracy and low-loss performance that make it ideal for industrial 5G, mmWave, and backhaul transceiver architectures.

Yet, when combined with high-power amplifier layers, lamination-induced stress and thermal gradients can introduce long-term reliability issues unless carefully engineered.

KKPCB addresses this through its hybrid stackup integration process, optimizing thermal balance and impedance alignment in complex multi-die RF modules.

Key Design Challenges in Duroid 6002 PCB-Based Transceivers

| Reliability Concern | Engineering Root Cause | System-Level Impact |

|---|---|---|

| Layer Misregistration | Differential CTE between Duroid 6002 and FR-4 | Impedance drift, signal reflection |

| Hotspot Formation | Uneven copper density in PA regions | Gain compression, thermal fatigue |

| Via Stress Fatigue | Repeated thermal cycling | Microvia cracking, degraded conductivity |

| Dielectric Skew | Uneven lamination pressure | Phase imbalance, poor beamforming control |

KKPCB’s Hybrid Stackup Engineering Framework

1. CTE-Balanced Material Architecture

-

Duroid 6002 (z-CTE ≈ 24 ppm/°C) paired with high-Tg FR-4 or ceramic prepreg layers.

-

Pre-simulation of mechanical strain using finite element thermal analysis to ensure even expansion.

-

Result: Layer shift < 25 µm across 8-layer PCB after 1000 thermal cycles (–55°C to +150°C).

2. Thermally Conductive Core Reinforcement

-

Incorporation of Cu-Mo-Cu or AlN thermal spreaders beneath PA zones.

-

Thermal resistance reduced by 18–25%, stabilizing power amplifier efficiency during sustained load.

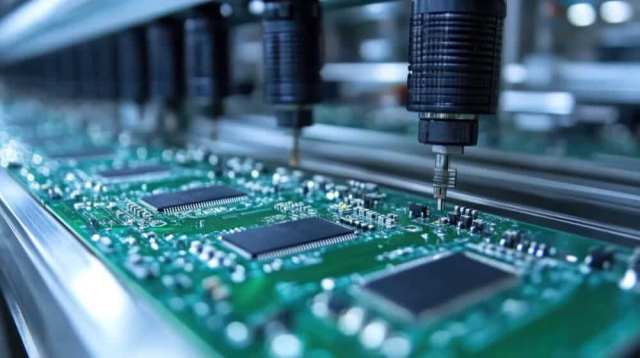

3.Optimized Lamination Process Control

-

Vacuum press at 190°C / 200 psi / 75 min to ensure void-free bonding.

-

Controlled cooling profile (< 2°C/min) minimizing resin shrinkage and warpage < 0.12 mm per 250 mm panel.

4.RF Impedance and Phase Matching

-

Inline VNA (up to 110 GHz) verification and TDR impedance mapping.

-

Typical impedance deviation ±4%, phase error < 1.2° across 60 GHz array boards.

Duroid 6002 PCB

Case Study — Industrial mmWave Transceiver Array Board (60 GHz)

Application: Factory automation radar and industrial IoT backhaul module

Client: EU-based 5G equipment manufacturer

Design Goal: Improve heat dissipation and maintain signal uniformity across 8-layer hybrid PCB.

| Performance Metric | Target | KKPCB Result |

|---|---|---|

| Power density | 12 W/cm² | 12.4 W/cm² stable |

| Thermal resistance | < 1.5°C/W | 1.28°C/W achieved |

| Impedance variation | ± 5% | ± 3.7% measured |

| Warpage post-lamination | < 0.15 mm | 0.11 mm verified |

Engineering Insight:

KKPCB used Duroid 6002 + CuMo core hybrid stackup, enabling uniform CTE and planar alignment during high-temperature exposure.

The board passed 1,000-cycle thermal shock testing without delamination or via fatigue, confirming long-term dimensional stability.

Reliability Validation and Testing

KKPCB implements a full IPC-TM-650-based validation protocol:

| Test Type | Condition | Result |

|---|---|---|

| Thermal cycling | –55°C ↔ +150°C / 1000 cycles | No delamination, via retention > 99.8% |

| Humidity resistance | 85°C / 85% RH / 1000 hrs | Df drift < 0.0002 |

| RF stability | 28–81 GHz range | Insertion loss variation < 0.05 dB/inch |

| Power stress test | 12 W/cm² continuous load | Stable gain, no micro-cracks |

Engineering Insight — Beyond Material to System Reliability

While Duroid 6002 provides low dielectric loss and stable CTE, real-world performance relies on stackup synergy and thermal balance engineering.

KKPCB’s hybrid design platform integrates simulation-driven lamination, CTE matching, and precision process monitoring—bridging the gap between design simulation and mass-production performance.

This enables OEMs in industrial mmWave communication, factory radar, and RF backhaul to achieve consistent power density and RF linearity without reliability trade-offs.

KKPCB’s Reliability & Traceability Framework

-

Material lot Dk/Df verification (humidity-controlled chamber)

-

3D lamination stress modeling for hybrid layer balance

-

Inline 110 GHz impedance mapping for each production batch

-

Accelerated aging & thermal fatigue testing for power circuits

-

Failure mode analysis (X-ray, cross-section microscopy)

Conclusion — Hybrid Reliability for High-Density RF Platforms

The combination of Duroid 6002’s dielectric stability and KKPCB’s hybrid lamination technology ensures that industrial mmWave transceivers maintain:

-

Consistent signal integrity across wide bandwidths

-

Stable thermal performance under sustained power load

-

Dimensional accuracy across hybrid stackups

KKPCB enables industrial RF engineers to transition from prototype-level accuracy to mass-production reliability, unlocking scalable, high-density mmWave architectures with verified power integrity.