Evolving Demands in Automotive and Aerospace RF Systems

As automotive radar, satellite navigation, and aerospace telemetry systems scale toward 24–77 GHz mmWave frequencies, RF PCBs face extreme conditions—high temperatures, vibration, and fluctuating humidity levels.

For engineers, ensuring signal stability, thermal endurance, and dielectric integrity over thousands of hours becomes a fundamental reliability challenge.

Rogers RO4003C has emerged as a preferred material for these systems, offering:

-

Low dielectric loss (Df = 0.0027 @ 10 GHz)

-

Stable dielectric constant (Dk = 3.38 ± 0.05)

-

Consistent performance up to +150 °C

However, even high-performance materials require systematic RF reliability testing and environmental endurance validation under production conditions to ensure repeatable field performance.

That’s where KKPCB’s RF reliability framework bridges material potential with real-world dependability.

Key Reliability Challenges in RO4003C PCB Production

| Reliability Concern | Root Cause | Typical Impact |

|---|---|---|

| Impedance Drift | Variations in resin thickness, lamination pressure | RF mismatch, phase shift |

| Delamination | CTE mismatch between RO4003C and FR-4 layers | Microcracks, open circuits |

| Thermal Oxidation | High-temperature aging (>150 °C) | Dk/Df drift, signal degradation |

| Moisture Absorption | 85 °C / 85 % RH conditions | Increased dielectric loss |

To address these issues, KKPCB integrates advanced process control, real-time impedance monitoring, and accelerated environmental testing aligned with IPC and AEC-Q200 standards.

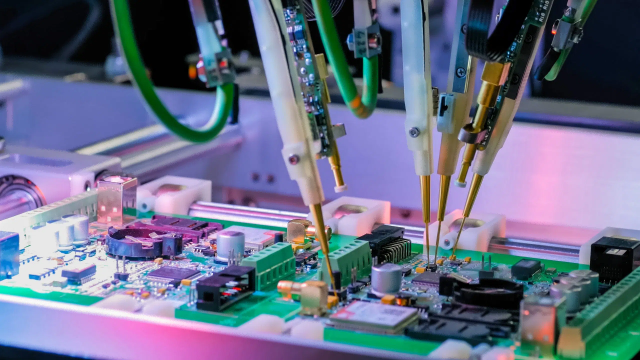

KKPCB’s RF Reliability Testing Framework

KKPCB’s framework combines electrical validation, mechanical endurance testing, and environmental simulation, ensuring every RO4003C PCB achieves long-term RF consistency in harsh operating conditions.

1. High-Frequency RF Validation

Testing Range: DC → 110 GHz

Equipment: VNA, TDR, microstrip calibration fixtures

Measured Parameters:

-

S11 / S21 loss characterization

-

Impedance uniformity (± 5 %)

-

Phase stability under thermal stress

Result Example:

After 1,000 hours at 150 °C, insertion loss drift measured only 0.03 dB/inch at 24 GHz — confirming stable Df and Dk values.

2. Thermal Cycling and Oxidation Endurance

Test Profile: –40 °C ↔ +150 °C for 1,000 cycles

Thermal Aging: +150 °C × 1,000 hours

Results:

-

Impedance shift < ± 3 %

-

No delamination or copper cracking under X-ray inspection

Engineering Insight:

In comparative trials, FR-4-based boards showed dielectric drift of > 0.009 Df, while RO4003C maintained 0.0027 ± 0.0002—proving its superior oxidation and thermal resilience.

3. Moisture and Humidity Resistance

Condition: 85 °C / 85 % RH × 1,000 hours

Observation:

-

Moisture absorption < 0.06 %

-

Dk/Df variation < 0.03

-

No resin whitening or via degradation

This confirms RO4003C’s low hygroscopic nature and KKPCB’s effective vacuum pre-bake and lamination profile.

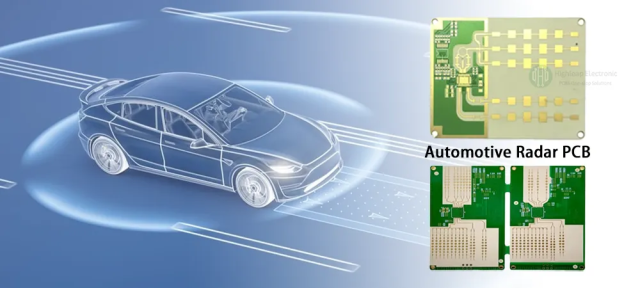

Case Study #1 — Automotive 77 GHz Radar Module

Customer: Tier-1 automotive radar manufacturer

Design Goal: Maintain signal stability and low phase noise after prolonged heat and vibration exposure

PCB Stackup: 6-layer hybrid — RO4003C RF layers + FR-4 control core

Testing Profile:

-

–40 °C ↔ +125 °C thermal cycling (1,000 cycles)

-

150 °C aging (1,000 hours)

-

Vibration: 10–2,000 Hz @ 0.75 mm amplitude

| Parameter | Before | After Reliability Test |

|---|---|---|

| Insertion Loss (S21) | 0.28 dB/in | 0.29 dB/in |

| Impedance Variation | ± 5.2 % | ± 3.5 % |

| Delamination Rate | 4.6 % | < 0.5 % |

Outcome:

Module achieved AEC-Q200 qualification, with zero layer separation and < 0.15 mm warpage per 250 mm panel.

Case Study #2 — Aerospace Phased-Array Antenna Module

Scenario: Satellite communication supplier required lightweight, dimensionally stable PCBs for 30 GHz phased-array front-ends.

Early FR-4 prototypes suffered from via fatigue and thermal expansion mismatch.

-

Converted design to RO4003C + ceramic hybrid stackup

-

Introduced multi-stage vacuum lamination (200 psi, 180 °C)

-

Applied outgassing bake prior to final press

Performance Results:

-

Outgassing < 0.25 % TML (ASTM E595)

-

Phase deviation < 1° from –55 °C to +125 °C

-

Impedance consistency ± 2.8 % across 32 channels

Impact:

The customer achieved 10.2 % power gain uniformity improvement and eliminated signal phase distortion at Ka-band frequencies.

KKPCB’s Reliability & Process Control Framework

To ensure batch-to-batch consistency, KKPCB enforces a five-tier quality and verification system:

-

Material Incoming QC: Dk/Df validation per Rogers datasheet

-

Lamination Simulation: Predict CTE mismatch and pressure curves

-

In-Line RF Testing: 110 GHz VNA verification during pilot run

-

Accelerated Environmental Tests: Thermal, humidity, and vibration cycles

-

Failure Mode Analysis: SEM + cross-section evaluation of microvias and dielectric layers

These controls ensure every RO4003C PCB meets IPC Class 3 and IATF 16949 reliability requirements.

Design & Process Insights

To achieve repeatable high-frequency reliability:

-

Maintain balanced hybrid stackup symmetry

-

Limit lamination cycles (< 2) to avoid Dk drift

-

Validate impedance using TDR & VNA correlation

-

Conduct thermal pre-bake (110 °C / 4 hr) before lamination

-

Perform post-build cross-section analysis on pilot lots

Conclusion — Proven Reliability in Harsh Environments

RO4003C PCBs offer an ideal balance of low loss, mechanical stability, and process reliability for next-generation automotive and aerospace systems.

Through KKPCB’s integrated RF reliability testing and environmental endurance validation, OEMs can confidently transition from prototype to large-scale production—achieving consistent impedance control, minimal drift, and aerospace-grade reliability.

Partner with KKPCB for Verified RF Reliability

KKPCB’s engineering team supports:

-

Custom RF reliability & thermal cycling programs

-

Stackup & lamination optimization for volume manufacturing

-

Impedance, phase, and oxidation stability validation

-

Full qualification data package per AEC-Q200 / IPC-TM-650

Contact KKPCB Engineering Support to discuss your RO4003C reliability project or request a technical DFM review.