PCB Assembly (PCBA) Services

Incoming Inspection

Inspection & Testing

PCB Assembly

Packing & Shipping

// Quality AssuranceRigorous Manufacturing Quality Control Process

- Process Control

- Testing & Inspection

- Shipping & Reliability

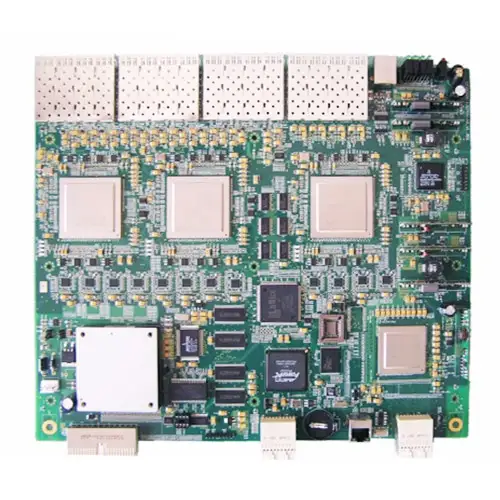

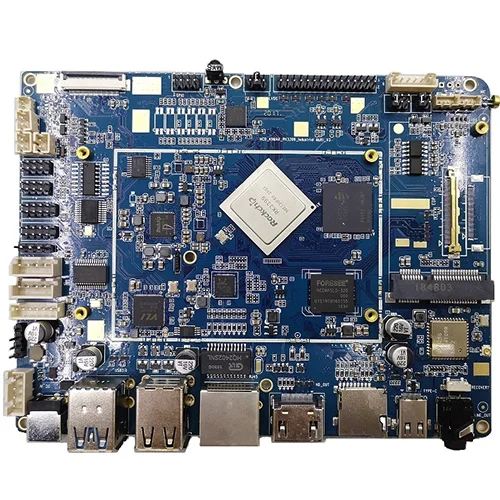

// PCB Manufacturing & AssemblyOne-Stop PCB Manufacturing & Assembly

We handle projects of any volume — from small-batch and low-volume assembly to basic through-hole technology, standard surface mount (SMT and THT), mixed assembly, and ultra-fine pitch BGA assembly.

We offer short lead times with no minimum order requirements. Our expertise covers complex double-sided PCB assembly, from component sourcing to final product testing.

PCB Assembly for Medical Ventilator

Medical Device PCB Assembly

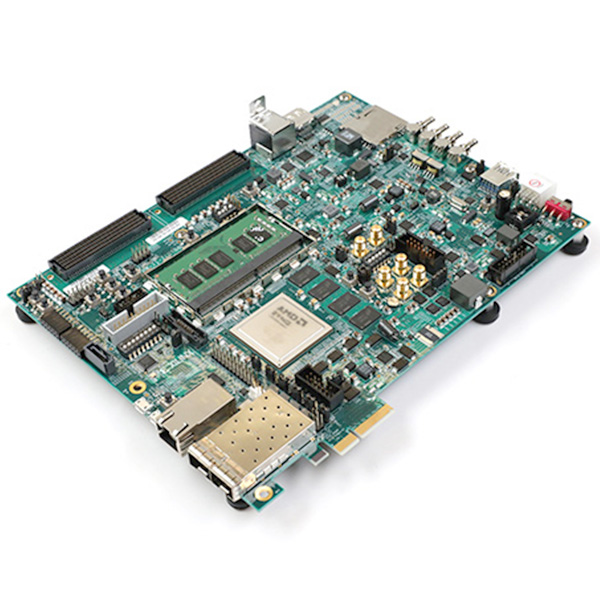

Touchscreen Motherboard Assembly

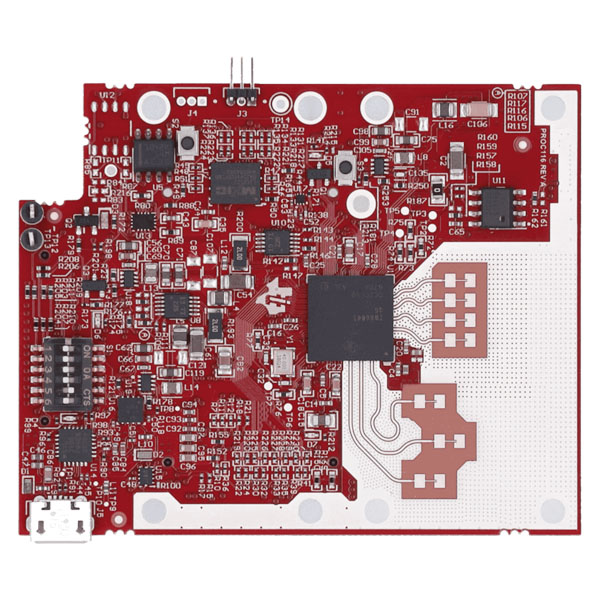

Prototype PCB Assembly

High-Frequency PCB Assembly

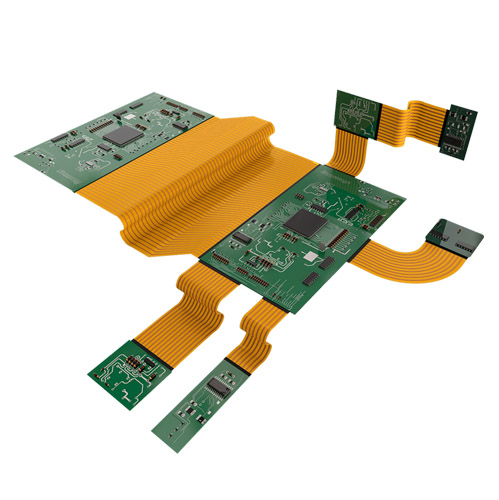

Flex-Rigid PCB Assembly

BGA PCB Assembly

SMT PCB Assembly

Flexible PCB Assembly

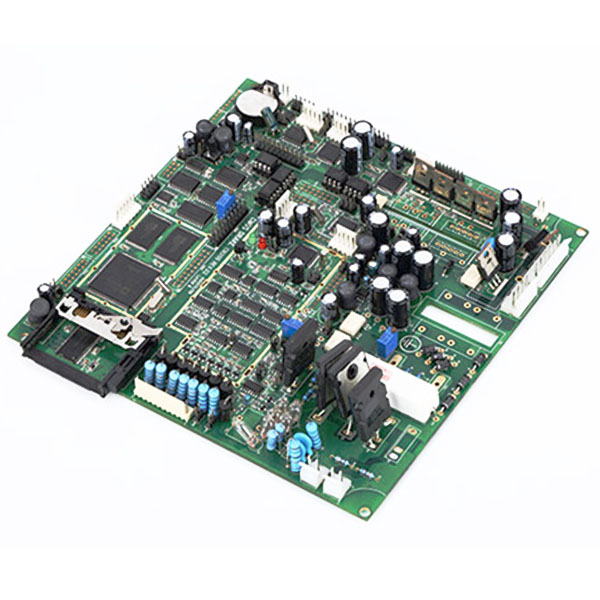

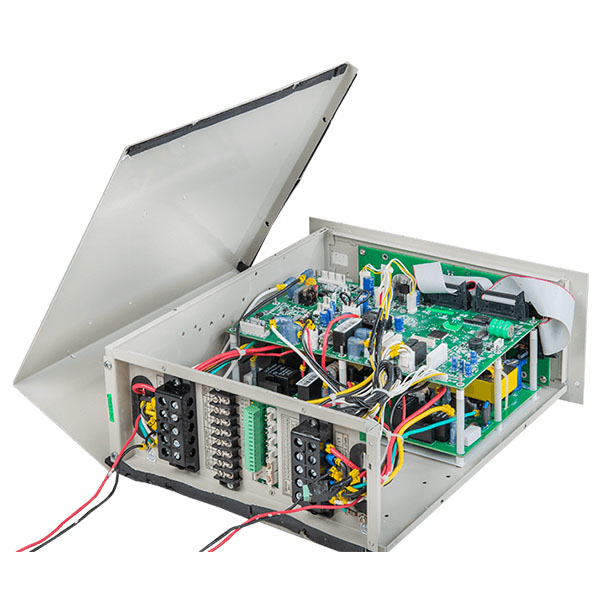

Industrial Control Equipment Box Build Assembly

Automotive Traction Control PCB Assembly

Energy Storage Module Inverter PCB Assembly

// Our Business PartnersWe Value Our Customers

// Industries We ServeFull-cycle Electronics Contract Manufacturing Service Provider

// Our ClientsElectronics Contract Manufacturing – Trusted by Clients in Over 15 Countries Worldwide

As a leading Chinese PCB manufacturing and assembly company, KKPCB provides a diverse range of high-quality printed circuit boards and comprehensive PCB assembly (PCBA) solutions tailored to meet the unique requirements of various industries. Trusted by companies across multiple sectors—including automotive, medical, consumer electronics, aerospace, digital communications, industrial control, smart home, and IoT—our services are recognized for their exceptional reliability, precision, and quality. With advanced manufacturing capabilities, rigorous quality control, and a client-centric approach, KKPCB ensures seamless integration from design and prototyping to full-scale production, helping businesses accelerate product development and succeed in competitive global markets.

// Frequently Asked Questions (FAQ)PCB Assembly (FAQ)

Yes. KKPCB provides one-stop services, including PCB fabrication, component sourcing, SMT assembly, through-hole assembly, testing, and final delivery.

o provide an accurate quotation, we need:

-

Gerber files for PCB manufacturing

-

BOM (Bill of Materials) with part numbers and quantities

-

Pick-and-Place (Centroid) file

-

Testing requirements (if any)

We support prototypes, small-batch, and medium-volume production. MOQ can be as low as 1 piece for prototypes.

Typical lead time ranges from 10–20 working days, depending on:

-

PCB fabrication (3–7 days)

-

Component procurement (3–10 days)

-

Assembly (3–7 days)

We follow several key PCB assembly standards to ensure quality and reliability, including IPC-A-610 for soldering and assembly workmanship, IPC-J-STD-001 for soldering practices, IPC-2221 for PCB design requirements, and ISO 9001 for quality management. Additionally, we adhere to RoHS compliance to limit hazardous materials, IPC-7711/7721 for rework and repair, and IPC-7351 for land pattern design. These standards collectively ensure high-quality assemblies and regulatory compliance.

Yes. We provide SMT, THT (DIP), mixed-assembly, and BGA rework services.

Our PCBA processes meet IPC, ISO 9001, RoHS, and automotive-grade standards (on request).

We offer:

-

AOI inspection

-

X-ray inspection

-

ICT (In-Circuit Testing)

-

FCT (Functional Circuit Testing)

Yes. We provide firmware programming, functional testing, and customer-defined validation services.

Yes. We support conformal coating, potting, mechanical assembly, and box-build services for turnkey projects.

All boards are packaged with ESD-safe materials, moisture-proof bags, and cushioning foam, then shipped via DHL, FedEx, UPS, or other preferred couriers.

Yes. We provide a standard 12-month warranty covering assembly workmanship and soldering quality.

We support expedited production and priority delivery for urgent projects. Lead time can be reduced to 5–7 working days depending on project complexity.