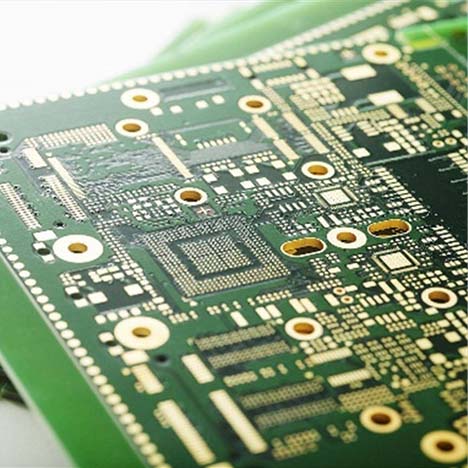

// PRODUCT SHOWCASEPCB Manufacturing and PCB Assembly

Our PCB manufacturing services include both large-scale and small-batch production, full turnkey PCB fabrication, contract manufacturing, and much more. KKPCB uses advanced methods and the latest PCB fabrication technologies to ensure high performance of the produced boards. Our experts are capable of handling any complex PCB manufacturing requirements. We understand all the needs of our clients and offer multilayer PCBs, quick-turn PCB fabrication, rigid-flex PCBs, high-frequency PCBs, ATE boards, metal-core PCBs, standard PCB manufacturing, custom PCB fabrication, hybrid PCB solutions, PCB testing, and much more.

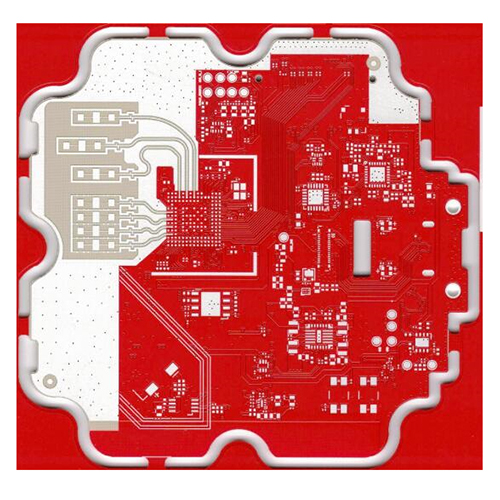

High-Frequency PCB

Burn-In Test PCB

10-Layer HDI PCB

Multilayer Flexible PCB

Industrial Control PCB

Hybrid High-Frequency PCB

FCB Testing PCB

Rigid-Flex PCB

Multilayer PCB

Backplane Thick Copper PCB

Rogers RO4003C PCB

Osprey Probe Card

IC Packaging Substrate

PCB Prototype

Digital Electronics PCB

// Zero Defects, Be ReliableWhy Choose Us

At KKPCB, we combine advanced technology, rigorous quality standards, and customer-focused services to deliver reliable, high-performance PCBs. From single-layer to complex multilayer PCB boards, HDI PCB, rigid-flex PCB, high-frequency PCB, and specialty PCBs, we handle every stage of production with precision and efficiency. Our certifications, including IPC, UL, RoHS, ISO, IATF, AS9100, and ISO13485, demonstrate our commitment to quality and compliance across industries such as industrial control, automotive, aerospace, medical, and telecommunications. With fast turnaround, 24/7 technical support, and innovative engineering solutions, we ensure that every project is completed on time, on budget, and to the highest standards.

- 24/7 real-time technical support

- Fast order fulfillment within 24 hours

- Quotation provided within 2 hours

- Efficient PCB engineering to reduce costs

- Reliable partnerships with reputable material suppliers

- Free DFM (Design for Manufacturability) service

- Traceable production process

- On-time delivery rate over 99%

- Line and space: 2 mil

- Laser-defined vias: 4 mil

- Via filling with conductive and non-conductive materials

- Dual back drilling

- Sequential lamination

- Mixed dielectrics

- Thick copper / thermal vias

- Blind / buried vias and stacked / staggered vias

- Multi-level cavity design

- Platinum-plated cavities and edges

- Long-short and stepped gold fingers

Experienced PCB Manufacturer with 10+ Years in the Industry

KKPCB offers advanced PCB manufacturing technologies and adheres to the highest quality standards in the electronics industry. We collaborate with over 6,000 high-tech R&D, manufacturing, and service enterprises across industries such as communications, industrial control, medical electronics, rail transportation, computers and peripherals, semiconductors, and automotive electronics.

Our unwavering commitment to technological leadership drives KKPCB to continuously pursue innovation. We are dedicated to building an innovative laboratory and engineering team capable of tackling new design challenges, including high-speed and high-density PCBs, RF and microwave PCB technologies, thermal management, miniaturization, and chip packaging.

-

Applications:

-

Base stations (antenna, power amplifier)

-

Microwave communications (General ODU, E-band ODU)

-

Collision avoidance systems (24 GHz, 77 GHz)

Solutions:

-

Multilayer PTFE PCBs

-

Flat hybrid and partially hybrid PCBs

-

High-temperature laminated PCBs

-

PCBs with embedded resistors

High-Frequency Material Options:

Rogers, Arlon, Isola, Teflon, Dupont, Taconic, Shengyi, and more. -

-

Applications:

-

Wired and wireless networks

-

Optical module PCBs

-

High-density line cards

-

Backplane PCBs

-

Servers and data storage systems

-

Enterprise networks

-

Network-attached storage (NAS)

-

Switches and routers

Solutions:

-

High-speed PCB solutions

-

PCB modeling and testing

-

Back-drilled PCBs

-

Impedance-controlled PCBs

-

PCBs with embedded capacitors

-

Advanced material applications

-

-

Applications:

-

Power amplifiers

-

Metal-core PCBs

-

High-integration PCBs

-

Renewable energy systems

-

Integrated inverter PCBs

-

Motor control PCBs

-

Battery Management System (BMS) PCBs

-

Charger PCBs

Solutions:

-

Power amplifier PCB solutions

-

Post-bonding PCBs

-

Overlap soldered PCBs

-

Low-power PCBs with embedded coins

-

Press-fit PCBs

-

Medium-power PCBs with partial heat dissipation

-

Power electronics PCB solutions

-

Secondary power supply PCBs

-

Busbar PCBs

-

Partial thick copper layer PCBs

-

Embedded high-power chip PCBs

-

-

Applications:

-

FC-CSP PCBs

-

SIP PCBs

-

HDI PCBs

-

Embedded PCBs

-

MEMS PCBs

-

ATE PCBs

-

PCBA Lamination

-

Rigid-Flex PCBs

-

Large RF PCBs

-

Multilayer RF PCBs

Solutions:

-

Packaging Substrates

-

Passive Embedding

-

Flip-Chip (FC)

-

Wire Bonding (WB)

Key Substrate Technologies:

-

Laser Via Filling PCBs

-

PTH (Plated Through-Hole) Via Filling

-

PCB Surface Finishing

-

Solder Masked PCBs

-

Embedded Devices

-

Embedded Flat Devices

-

Embedded Discrete Devices

-

Embedded Chips

-

Rigid-Flex PCBs

-

HDI RF PCBs

-

High-Frequency RF PCBs

-

Hybrid RF PCBs

-

High-Speed FPCs

-

Embedded RF PCBs

-

Semi-Flex PCBs

-

RF PCBs with Heat Sinks

-

RF PCBs with Thick Copper

-

SIP RF PCBs

-

// Industries We ServeFull-cycle Electronics Contract Manufacturing Service Provider

// Our Business PartnersWe Value Our Customers

// Our ClientsElectronics Contract Manufacturing – Trusted by Clients in Over 15 Countries Worldwide

As a leading Chinese PCB manufacturing and assembly company, KKPCB provides a diverse range of high-quality printed circuit boards and comprehensive PCB assembly (PCBA) solutions tailored to meet the unique requirements of various industries. Trusted by companies across multiple sectors—including automotive, medical, consumer electronics, aerospace, digital communications, industrial control, smart home, and IoT—our services are recognized for their exceptional reliability, precision, and quality. With advanced manufacturing capabilities, rigorous quality control, and a client-centric approach, KKPCB ensures seamless integration from design and prototyping to full-scale production, helping businesses accelerate product development and succeed in competitive global markets.

// Frequently Asked Questions (FAQ)Questions About PCB Manufacturing

When selecting a PCB manufacturing supplier, you should focus on key attributes such as quality and certification, manufacturing capabilities, cost-effectiveness, customer service, experience and reputation, customization capabilities, environmental and social responsibility, and geographical location.

The types of surface finishes in PCB manufacturing include Hot Air Solder Leveling (HASL), which covers with tin-lead alloy or lead-free alloy, commonly used for general applications; Electroless Nickel Immersion Gold (ENIG), which plates a layer of nickel and gold, providing a smooth and solderable surface, suitable for high-end applications; Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG), which has multiple layers (nickel, palladium, gold) offering excellent soldering and electrical performance; Immersion Tin, which covers a layer of tin ensuring good solderability and electrical connections; Immersion Silver, which covers a layer of silver providing excellent solderability and conductivity; and Organic Solderability Preservative (OSP), which uses organic compounds to protect copper, suitable for short-term storage and low-cost applications.

To obtain PCB manufacturing services, you need to prepare the following detailed files and information:

- Gerber Files: These contain PCB layer information such as copper layers, solder mask layers, and silk screen layers, used for manufacturing and inspecting the specific layout and design of the PCB.

- NC Drill File: Includes information on all hole positions and sizes required to be drilled on the PCB, ensuring accurate placement of component mounting holes and vias.

- BOM (Bill of Materials): This lists all components used on the PCB, including details like component names, part numbers, quantities, and specifications, aiding manufacturers in preparing and procuring necessary parts and materials.

- PCB Layout File: These files display the specific layout and positions of all components on the PCB, including pin locations and connection details, crucial for manufacturing.

- Mechanical Drawing: Provides detailed descriptions of the PCB’s dimensions, board thickness, hole positions, and edge cuts, ensuring the PCB shape and size align with design requirements.

- Assembly Drawing: These drawings indicate the placement, orientation, and correct assembly method for each component on the PCB, ensuring accurate assembly processes.

- Special Requirement Specifications: If there are specific manufacturing requirements or needs, such as particular surface finish requirements (e.g., ENIG or HASL), special material requirements, or testing requirements, detailed specifications are necessary to ensure manufacturers can comply with your requests.

- Test Specifications: Clearly outlines various testing requirements and standards, including electrical tests, functional tests, or reliability tests, ensuring the final PCB meets expected performance and quality standards.

Preparing comprehensive files and information helps manufacturers accurately understand and execute your PCB manufacturing requirements, ensuring the production of high-quality PCB products as expected.

If the PCB product does not meet your requirements, you can take the following steps:

- Inspect and Confirm the Issue:

- Internal Inspection: Carefully examine the received PCB and document all areas that do not meet the requirements, such as appearance defects, electrical issues, or functional failures.

- Review Documentation: Recheck the design files and specifications you provided to the manufacturer to confirm whether the issue originated from the design or manufacturing process.

- Contact the Manufacturer:

- Detailed Problem Description: Provide the manufacturer with a detailed description, including photos, videos, and test data, clearly explaining the non-conforming aspects.

- Provide Feedback and Evidence: Attach relevant documents and evidence, such as inspection reports and design files, to help the manufacturer understand the specific issue.

- Rework or Replacement:

- Rework or Repair: If the issue can be fixed, agree with the manufacturer on rework or repair, and confirm the time and cost involved.

- Remanufacture: If the issue is severe and cannot be fixed, request the manufacturer to remanufacture new products that meet the requirements.

- Quality Improvement:

- Root Cause Analysis: Work with the manufacturer to analyze the root cause of the issue to prevent similar problems in the future.

- Process Improvement: Improve the design and manufacturing processes to ensure future products meet the requirements.

These steps can help you effectively address non-conforming PCB products, ensuring your project proceeds smoothly and meets the expected quality standards.

At KKPCB, we regularly work with the flowing materials

-

- FR4 (Tg – 135C, 145C, 170C, 180C) FR406, 370HR and FR408

- Rogers Ultralam 2000

- Rogers RO4350

- Rogers RO4003

- Polyimide

- Teflon

- Black FR4

- Arlon AR350

- Getek Copper Clad Thermal Substrates

- Hybrid (Rogers and FR4) BT Epoxy

- Nelco 4013

- Metal Core Materials

The main types of PCB circuit boards we produce are:Single&Double Sided PCB, Multilayer PCB, HDI PCB, Backplane PCB, High Frequency PCB & RF Microwave PCB, Hybrid PCB, Heavy Copper PCB, Aluminum PCB, Embedded PCB, Cavity PCB, Gold Finger PCB, Any-layer PCB, Ceramic PCB,IC Substrate PCB, Flex PCB, Rigid-flex PCB, Large PCB, Thermal Management PCB, Wire Bonding PCB.

Common tests in the PCB manufacturing process include the following:

- Optical Inspection (AOI):

- Automated Optical Inspection (AOI): Uses cameras to scan the PCB and automatically detect defects such as shorts, opens, solder defects, and missing components.

- Electrical Testing (ET):

- Flying Probe Test: Used for low-volume production or prototype PCBs, where flying probes test the circuit’s connectivity.

- Bed of Nails Test: Used for high-volume production, where fixed probes test the circuit’s connectivity and electrical performance.

- X-Ray Inspection:

- 2D X-Ray Inspection: Used to inspect the internal structure of the PCB, especially for multilayer boards or complex packages like BGAs (Ball Grid Arrays).

- 3D X-Ray Inspection: Provides a detailed three-dimensional view for further analysis of solder joints and internal structures.

- Functional Testing:

- Simulates real working conditions to test the PCB’s functionality and performance, ensuring its reliability in actual applications.

- Solder Quality Inspection:

- Visual Inspection: Manual inspection of solder joints and component placement quality.

- Infrared Inspection: Uses thermal imaging to detect heat generated during soldering, evaluating solder quality.

- Environmental Testing:

- Thermal Cycling Test: Exposes the PCB to extreme temperature cycles to test its reliability under high and low-temperature conditions.

- Humidity Test: Tests the PCB’s performance in high humidity environments.

- Impedance Testing:

- Ensures that specific signal lines have controlled impedance within the design range, especially important in high-frequency applications.

- High-Potential (Hi-Pot) Testing:

- Tests the PCB’s insulation performance, ensuring the insulation strength between different circuits.

These tests collectively ensure the quality and reliability of PCBs during the manufacturing process, meeting design specifications and customer requirements.

PCB manufacturing services are applied in various industries, covering a wide range of electronic products and systems. Here are some major application industries:

- Consumer Electronics:

- Smartphones, tablets, laptops, smartwatches, and other personal electronic devices.

- Automotive Electronics:

- Car infotainment systems, dashboards, electronic control units (ECU), navigation systems, ADAS (Advanced Driver Assistance Systems), and battery management systems for electric vehicles.

- Medical Devices:

- Medical monitoring devices, imaging systems, diagnostic equipment, and wearable health devices.

- Telecommunications and Networking:

- Routers, switches, servers, base stations, and fiber optic communication equipment.

- Industrial Control and Automation:

- Industrial automation systems, PLCs (Programmable Logic Controllers), sensors, robots, and factory automation equipment.

- Aerospace and Defense:

- Avionics, communication systems, radar systems, missile control systems, and satellite communication equipment.

- Computers and Data Storage:

- Desktops, servers, data storage devices, and cloud computing infrastructure.

- Home Appliances:

- Smart home devices, televisions, audio systems, air conditioners, and home appliance control systems.

- Power and Energy:

- Renewable energy systems (such as solar and wind controllers), smart grid devices, and power management systems.

- Internet of Things (IoT):

- IoT devices and sensors, smart city infrastructure, and connected devices.

These industries use PCB manufacturing services to develop and produce their electronic products, meeting the evolving technological and market demands.

- 1. Quality ControlBe it ISO 9001:2015 or ISO 13458:2016 quality management systems, we make sure to provide our customers with the highest quality circuit board fabrication. Our multifaceted experts render the best quality PCB services right from layout to final delivery.2. Quick Turn PCB FabricationWe provide quick-turn pre-production PCB fabrication and multi-layer fabrication with high-count and dense multilayered PCB services at a faster time-to-market. We have built a very responsive culture to ship larger fabrications of PCB numbers in a short period of time.

3. Safety

Safety and security are primary prerequisites of our printed circuit board fabrication and hence we carry out all the fabrication solutions and assembly processes as per the best industry standards, rules, and guidelines.

4. Top-notch Customer Retention

A full-fledged PCB fabrication right from the product layout, manufacturing, warehousing, and shipping have not just garnered us a global customer base but also an incredible customer retention rate.