Warm-Metallurgy Breakthrough Expands the Capabilities of Inorganic Semiconductors

Inorganic semiconductors are known for their excellent electrical properties but suffer from extreme brittleness at room temperature. This limitation has historically required complex, costly deposition technologies and made these materials unsuitable for flexible and wearable electronics.

Recent research from Chinese scientists presents a major breakthrough, offering a new pathway for processing brittle semiconductor materials.

Temperature-Dependent Plasticity Enables New Processing Window

The research team developed a temperature-dependent plasticity model, revealing that materials considered highly brittle at room temperature—such as Cu₂Se, Ag₂Se, and Bi₉₀Sb₁₀—exhibit excellent ductility when heated to below ~200°C.

At these moderate temperatures, the atomic structure becomes capable of deformation without fracture, allowing the material to stretch, bend, and form more easily.

This discovery opens the door to a range of new manufacturing methods previously impossible for these semiconductors.

Warm-Metallurgy Processing: Rolling, Pressing, and Extrusion

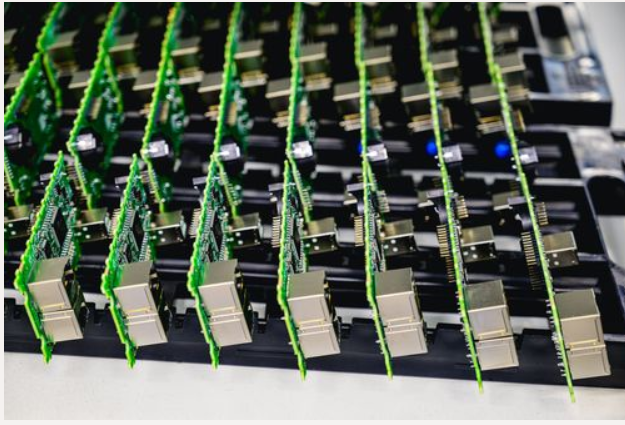

Based on the plasticity model, researchers demonstrated that brittle semiconductors can be processed using warm-metallurgy techniques typically used for metals, including:

-

Rolling

-

Pressing

-

Extrusion

Record-Breaking Ductility Example: Ag₂Se

An Ag₂Se semiconductor wafer achieved an astounding:

✔ 3000% elongation under warm processing conditions.

This result proves that highly brittle inorganic semiconductors can be transformed into ductile, formable materials suitable for scalable production.

Self-Supported Semiconductor Films via Thermal Evaporation

In parallel, the study demonstrated the ability to produce self-supported semiconductor films using thermal evaporation—a process typically requiring rigid substrates.

Key advantages include:

-

No substrate required

-

Film thickness from micrometers to millimeters

-

High crystallinity maintained

-

Physical properties comparable to bulk crystals

-

Ideal for flexible electronics and high-performance thermoelectric devices

This makes fabrication more versatile and cost-effective for industrial applications.

Ultra-High Carrier Mobility: Surpassing Silicon and 2D Materials

Films of Ag₂Te, AgCuSe, and Ag₂Se with thicknesses of 5–10 µm exhibited remarkable electrical performance:

-

Carrier mobility: 1000–5000 cm²·V⁻¹·s⁻¹

-

~4× higher than crystalline silicon

-

Orders of magnitude higher than most 2D or organic semiconductor materials

These results mark a major leap forward, significantly broadening the application potential of inorganic semiconductors.

Applications and Future Prospects

This new warm-metallurgy semiconductor processing opens opportunities for:

-

Wearable devices

-

High-performance thermoelectric modules

-

Lightweight self-supported semiconductor components

-

Large-area, low-cost semiconductor manufacturing

By overcoming the brittleness barrier, inorganic semiconductors can now enter markets that previously favored organic or polymer-based materials.

The discovery of temperature-dependent plasticity and the development of warm-metallurgy processing represent a major step forward for semiconductor manufacturing.

With high ductility, substrate-free film formation, and record-breaking carrier mobility, inorganic semiconductors are poised to play a central role in the next generation of flexible and high-performance electronics.