// Energy IndustryRenewable Energy PCB Assembly service

KKPCB is proud to be your trusted partner for PCB manufacturing services supporting a wide range of applications in the renewable and solar energy industries. We provide advanced electronics manufacturing services for emerging technologies, including mechatronics, green energy, solar, wind, geothermal, and nanotechnology. The assemblies we build for the renewable energy sector help reduce environmental impact, improve product quality, and enhance overall performance.

At KKPCB, we turn cutting-edge ideas into reality. Our focus is on producing eco-friendly and reliable PCB assemblies that are both efficient and durable. We follow a well-defined manufacturing process designed to minimize waste and reduce water and electricity consumption. Our team of experienced engineers uses non-hazardous materials that comply with the highest quality standards. Additionally, we offer lead-free and RoHS-compliant PCB assembly solutions, ensuring your products are both sustainable and high-performance.

// Renewable EnergyOur Renewable Energy Electronics Manufacturing Services

PCB Assembly

Cable & Wire Harness

Box build assembly

PCB Circuit board uses in renewable energy industry

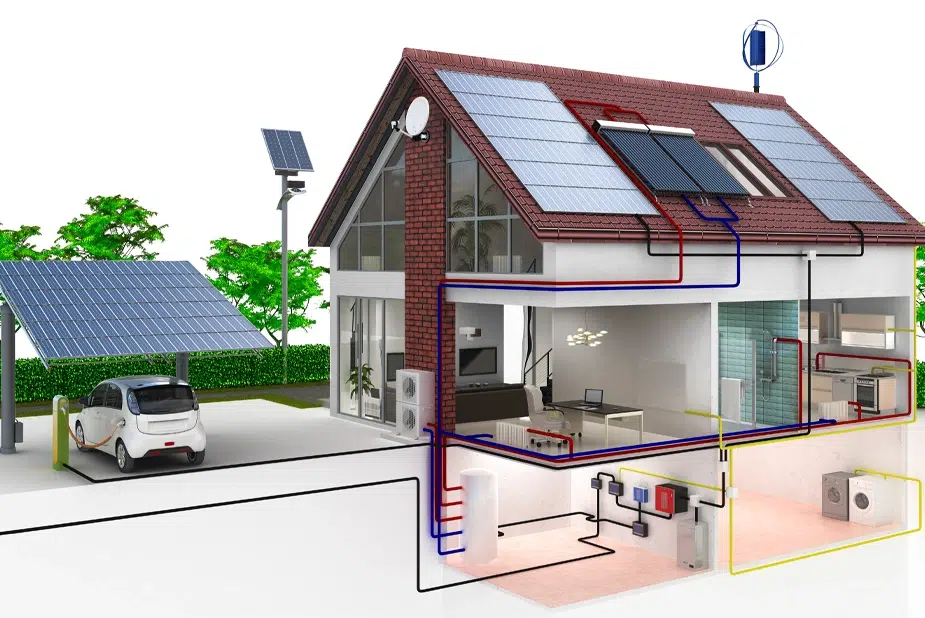

With the rise of renewable energy technology, PCB boards are being used in a variety of industries. From wind energy to solar power, to energy management systems and agriculture, PCBs are playing a key role in the renewable energy industry. These boards must meet environmental standards and be compatible with high-power circuits. In order to meet these requirements, PCB manufacturers are taking additional steps to make PCBs that are environmentally friendly.

PCB boards are essential to the renewable energy industry. They can help generate energy, measure moisture content in the air, and track the revolutions of wind turbines. The quality of the PCB board is crucial to the overall performance and reliability of the system.

Geothermal energy is one example of a renewable energy technology. As a form of energy, geothermal energy can be used to heat buildings in the winter and cool them in the summer. The United States is working towards using more renewable energy resources in order to reduce its carbon footprint. The International Renewable Energy Agency (IRENA) has set targets for 2030 to double the amount of renewable energy consumed worldwide. These targets are a great opportunity for the PCB industry.

Heavy copper PCB is used in solar energy storage systems and wind energy equipment. This metal has high rigidity and a low thermal conductivity, making it a perfect material for PCBs.

PCB board application in renewable energy industry

The renewable energy industry is a growing one and PCB technology has a role to play in this industry. PCBs can be used to build sensors that measure moisture in the air, monitor wind turbine revolutions, and more. The International Renewable Energy Agency (IRENA) has set a goal of doubling the amount of renewal energy used in the world by 2030. Reliable and cost-effective PCBs make this possible.

PCBs are essential for the harvesting and conversion of energy from renewable sources and other sources. These boards also provide the power and sensory control to monitor energy consumption. Some of the most common devices used in this industry include DC-DC converters, inverters, power supplies, and DAQ boards. Battery storage systems and power distribution are other common uses for PCBs in the renewable energy industry.

// Frequently Asked Questions (FAQ)PCB Assembly for Renewable Energy Frequently Asked Questions

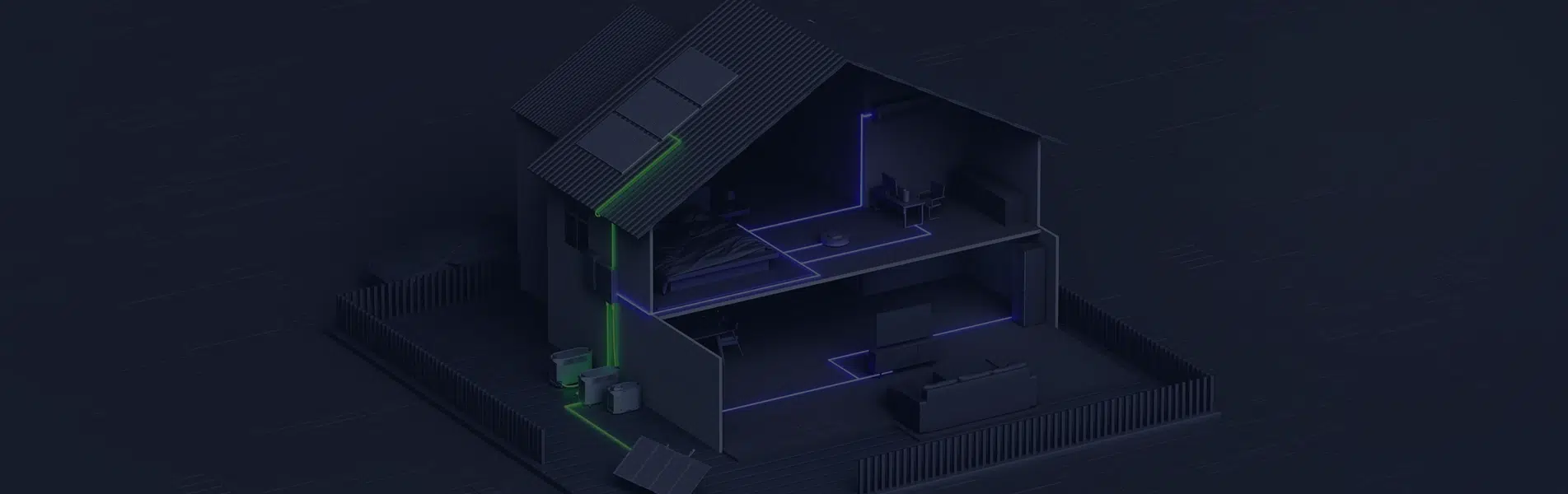

Renewable Energy PCBs are essential for various applications, including solar power systems (inverters and charge controllers), wind turbines (control systems and power converters), energy storage systems (battery management and controllers), hydropower systems, electric vehicle charging stations, smart grid technologies, and residential and commercial renewable energy setups. They ensure efficient management, optimization, and monitoring of renewable energy systems, contributing to more effective and sustainable energy solutions.

When designing PCBs for renewable energy applications, it is crucial to consider durability for harsh environments, effective thermal management, and high voltage/current handling. The design should optimize power efficiency, use reliable components, and ensure electrical and signal integrity. Compliance with industry standards, compatibility with other systems, ease of manufacturability, and scalability are also important. Addressing these factors ensures the PCB’s reliability, performance, and efficiency in renewable energy systems.

Renewable Energy PCB assembly types include Surface-Mount Technology (SMT) for high-density designs, Through-Hole Technology (THT) for robust mechanical connections, and Mixed Technology combining both methods for complex designs. Flexible PCB Assembly caters to applications with constrained spaces, while Rigid-Flex PCB Assembly integrates both rigid and flexible sections for optimal space use and durability. Hybrid PCB Assembly combines traditional and advanced technologies for specialized needs. Each type is selected based on the specific requirements of the renewable energy system.

Renewable Energy PCB assembly requires Gerber files for layer details, Bill of Materials (BOM) for component lists, Pick and Place files for accurate component placement, schematic diagrams for electrical design, assembly drawings for component placement and soldering, stencil files for solder paste application, test specifications for quality assurance, and Design for Assembly (DFA) guidelines to optimize the assembly process. These files ensure precise manufacturing, efficient assembly, and reliable performance of PCBs in renewable energy systems.