// Medical PCB Assembly ServicesMedical PCB Manufacturing & Assembly

KKPCB is a medical PCB manufacturer based in Shenzhen, China who has extensive years of experience spanning 2 decades in offering world-class medical PCB assembly and manufacturing services. We have the capacity to assemble everything from head to toe of the medical diagnosis and treatment devices, healthcare monitoring devices, advanced therapeutic treatment devices, and other critical medical electronics.

We stay on top of the ever-evolving trends in the medical and dental industry and understand the critical nature of these devices based on which human lives have relied. So, we make sure to incorporate high-precision and error-free boards to achieve the level of sophistication required for these life-saving devices. We provide end-to-end solutions to our clients from the medical industry and save them the time and cost overheads of moving across multiple vendors.

With a brilliant team of IPC-trained personnel, we ensure to strictly comply with the IPC class 3 standards. We also adhere to the RoHS and lead-free PCB assembly requirements of the medical industry.

// MEDICAL PCB ASSEMBLYOur Medical PCB Assembly Services Includes

// SELECTING THE BEST MEDICAL DEVICE SOLUTIONS SUPPLIERMedical PCB Assembly Techniques

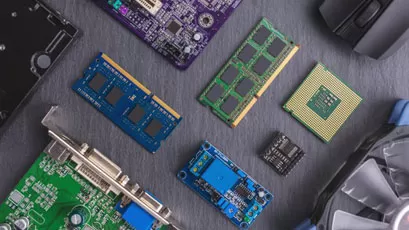

KKPCB follows a cost-effective and efficient process for placing and assembling electronic components on the surfaces of medical printed circuit boards accurately and precisely. We have experience with all the three assembly technologies –

- Surface-Mount Technology (SMT)

- Through-Hole Technique (THT)

- Mixed (Both SMT and THT)

However, we recommend Surface Mount Technology to assemble PCBs for medical systems. You can utilize the latest automated equipment for building high-level quality and compact-sized PCBs. We follow the surface mount technology assembly process for building lighter and compact boards and for meeting the unique requirements of the medical systems during the circuit board assembly. Our engineers at KKPCB are capable of creating higher density and increasingly complex circuit boards even in smaller assemblies at envious precision.

Through SMT techniques, we build extremely fast and cost-effective medical PCB assemblies. Through SMT technology, we also reduce the overall assembling time by eliminating the need for drilling holes in the PCB. In addition to SMT PCB assembly, we are also capable of providing conventional through-hole technique. Through-hole mounting is used when we have to manufacture robust medical devices and also during the prototyping stages of the build.

01Medical PCB Assembly Capabilities

X-ray Machine

IoT Usage

| Capabilities | |

|---|---|

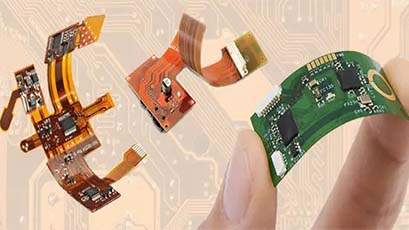

| Types of Medical PCB Assemblies | Rigid, Flexible, and Rigid-Flex |

| PCB Materials | Standard FR4 Tg 140°C, Tg 170°C, and Tg 180°C, Copper Base, and Aluminum Base |

| RoHS Compliance | Yes |

| Surface Finish Options | Hot Air Solder Leveling (HASL), Lead-Free HASL, Immersion Tin, Immersion Silver, Electroless Nickel/Immersion Gold (ENIG), and many others |

| Additional PCB Options | Fine Pitch, BGA and Micro BGA Assembly, ESD, Moisture Sensitivity, FIFO Procedures |

02Medical PCB Assembly Testing Capabilities

KKPCB follows nothing but the best practices during the PCB assembly process. We are uniquely equipped to handle any challenges that deteriorate the quality of the systems and also help you bring only reliable medical devices to the market. As it is a known thing that all medical PCBs should comply with strict sanitary and quality standards, we make sure the PCBs or other electronics that need to go into your device systems meet these highest quality benchmarks.

We also perform the assembly and prototype services in small batches as it gives us ample time to perform quality assurance checks at critical moments throughout the medical PCB design and manufacturing process. We perform a final inspection using an X-ray inspection or Automated Optical inspection. Our X-ray inspection station is top-notch and features digital control, an X-Y table, and an image intensifier. Our engineers use this to ensure high-level quality controls for medical applications.

Testing Capabilities

-

- X-Ray Inspection

- Automated Optical Inspection (AOI)

- Temperature Testing

- Camera Inspection

- Product-specific Functional Testing

- Fly-probe Testing (To validate component Placement)

- In-circuit Testing (To detect parametric or design failures)

- Functional Testing (To control behavior and functions of PCB)

Follow below given process to get medical PCB assembly quote –

- Go to PCB assembly quote page.

- Collect important PCB design files to add in assembly quote page.

- Enter details in quote page and upload your design files.

- Answer security question and hit submit button.

- If you have any query, contact us on sales@kkpcb.com

/MEDICAL DEVICE APPLICATIONSMultifarious Usage of Medical PCB Assembly

PCB Assembly

Cable & Wire Harness

Our solutions support a wide range of medical technologies, including diagnostic and patient monitoring equipment, surgical instruments, imaging systems, therapeutic devices, rehabilitation and assistive technologies, laboratory equipment, prosthetics and orthotics, dental devices, and advanced telemedicine systems. With rigorous quality control and compliance to medical standards, we deliver assemblies that ensure safety, reliability, and long-term performance in the medical field.

Box build assembly

Our expertise extends to a wide range of applications, including patient monitoring systems, surgical equipment control units, diagnostic device enclosures, imaging system consoles, laboratory instruments, therapeutic device housings, rehabilitation equipment panels, medical device interface modules, telemedicine enclosures, and dental equipment control units.

// Frequently Asked Questions (FAQ)Medical PCB Assembly Frequently Asked Questions

Medical PCBs are designed specifically for making medical devices and systems. These are built by taking different lab settings and test scenarios into consideration.

Small and denser printed circuit boards are the need of the hour! There is a great reduction in the component placement density which helps in reducing the error margin. These compact boards also help in heat dissipation and hence the latest medical systems are incorporating compact boards.

With plenty of options available for you, you can go for a certified and experienced CM for building error-free and top-quality PCB assemblies for medical systems. The CM you are choosing should be aware and must be meeting the rigorous medical standards. An experienced contract manufacturing (CM) is an excellent option as it takes away the hassles from taking your products to the market.

KKPCB has 4 decades of experience in PCB assembly services. We are also an IPC-certified company and take care of all the regulations levied down for the medical PCB assembly systems. We also make sure to keep the turnaround time to the lowest when compared to the other CMs. We also have a strong supply chain that lets us pick only the high-quality equipment to build sophisticated medical devices. You can also rely on our brilliant team for any sort of support.

To help you get started, we furnish some information for DFM checks and you would be able to easily see and download DRC files. You can request a quick PCB assembly service quote from here.

With Medical PCBs, the following are made possible

- Data-driven Medicine

- Electronic health records

- Mobile health

- Wearable devices

We have a reliable supply chain of vendors and distributors who supply only good-quality components for the PCB build. We also employ methods like traceability to avoid the usage of counterfeit components.

KKPCB is a complete turnkey solution provider. We make sure to keep your costs down and honor your broader business goals. We make the process smooth and trouble-free to avoid unnecessary iterations and cost overheads. Let us know your medical circuit board requirements, we will provide you the final quote.

Well, that entirely depends on the device you want. But we have experience in effectively utilizing the commercial-off-the-shelf components (COTS) that speed up the design process. These COTS that we use are from a reputable source and are meant to improve the efficacy of the medical PCBs.

Our engineers follow a meticulous process for balancing both customization and quality and are ever-equipped to meet any unique requirements you have to assemble your circuit boards. We do it in small batches with superior attention to detail. We also automate certain components for high-volume orders.