// high quality industrial PCB assembly ServicesIndustrial PCB Assembly

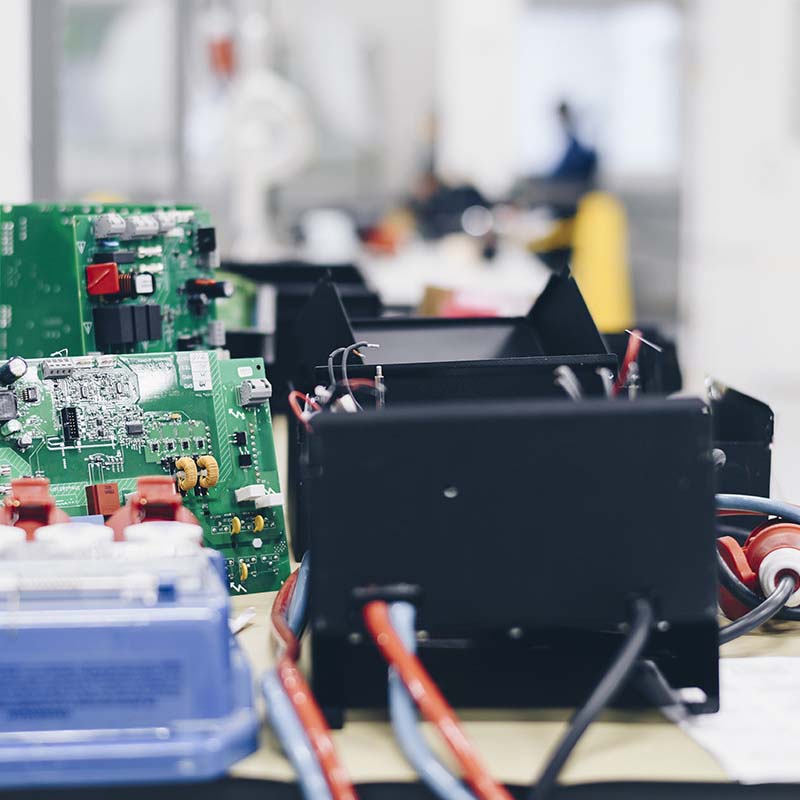

When it comes to high-quality industrial PCB manufacturing and assembly, KKPCB stands out as a trusted one-stop solution provider. With over a decade of proven expertise, we have earned the confidence of global clients by delivering complex, high-reliability PCB and PCBA solutions that power critical industrial applications.

Our strength lies in combining advanced technologies, stringent quality systems, and a team of seasoned experts to develop state-of-the-art industrial circuit boards that meet the most demanding standards. We go beyond manufacturing—we partner with our clients to provide tailored solutions that accelerate innovation, reduce time-to-market, and enhance long-term product reliability.

Why Industrial Leaders Choose KKPCB

-

Reliability in Harsh Environments – Our industrial PCBs are designed to withstand extreme temperatures, moisture, dust, shock, vibration, and other challenging operating conditions.

-

High-Precision Manufacturing – From fine-pitch components to high-layer-count and rigid-flex designs, we ensure accuracy and consistency across every production batch.

-

OEM-Focused Solutions – With 10+ years of experience supporting OEMs in industrial, commercial, automotive, energy, and IoT sectors, we understand your critical requirements and provide complete turnkey assembly services.

-

Advanced Facilities – Our production lines are equipped with the latest SMT lines, AOI/X-ray inspection, ICT/FCT testing, and full traceability systems to guarantee product quality.

-

Flexible Volumes, On-Time Delivery – Whether small, medium, or large-scale production, KKPCB adapts to your needs while ensuring reliable lead times and supply chain efficiency.

Comprehensive Capabilities

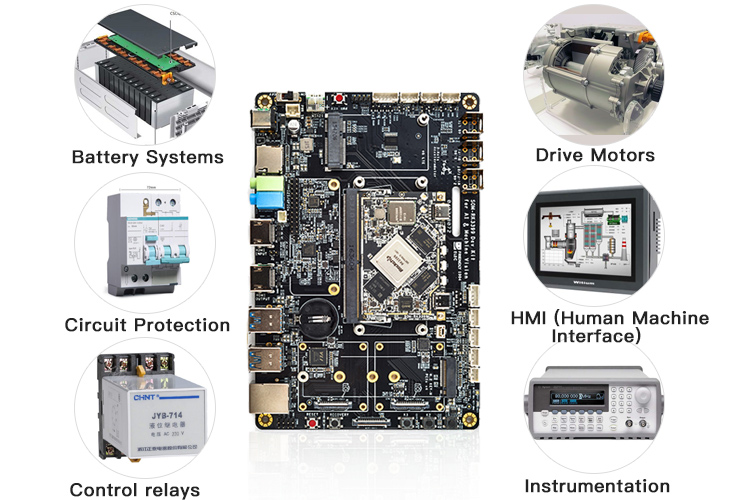

We support a wide range of industrial applications—from sensor and monitoring systems to heavy equipment, energy systems, and household appliances. Our capabilities include:

-

PCB Assembly (prototype to mass production)

-

Enclosure Assembly

-

Cable & Harness Assembly

-

Complete Turnkey PCBA Solutions

-

High-Mix, Low-to-Medium Volume Production for complex industrial electronics

// The Preferred Partner for Industrial PCB AssemblyCharacteristics of Industrial PCB Manufacturing

// Industrial PCB assembly ServicesApplication of Industrial PCB Assembly

PCB Assembly

Cable & Wire Harness

Box build assembly

// Industrial Electronics PCB Assembly CapabilitiesIndustrial PCB Manufacturing Process

The Industrial PCB manufacturing process involves the following steps:

PCB Design and Layout – This is one of the most crucial stage of the entire manufacturing process. A successful design supports the functioning of the device hence due attention needs to be paid to this stage. PCB design, of course, is influenced by the exact requirements of the industrial application and the environment it needs to work under. It is also influenced by the nature of users as well as access to resources.

Prototyping – Having a functional PCB prototype in place, to a large extent, mitigates the probability of any costly errors at a later stage. The prototype can ensure that both the function and features are tested. It is worth spending more time and investment on prototypes, as once this is in place, you can proceed to assembly.

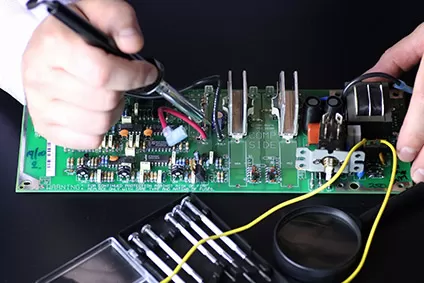

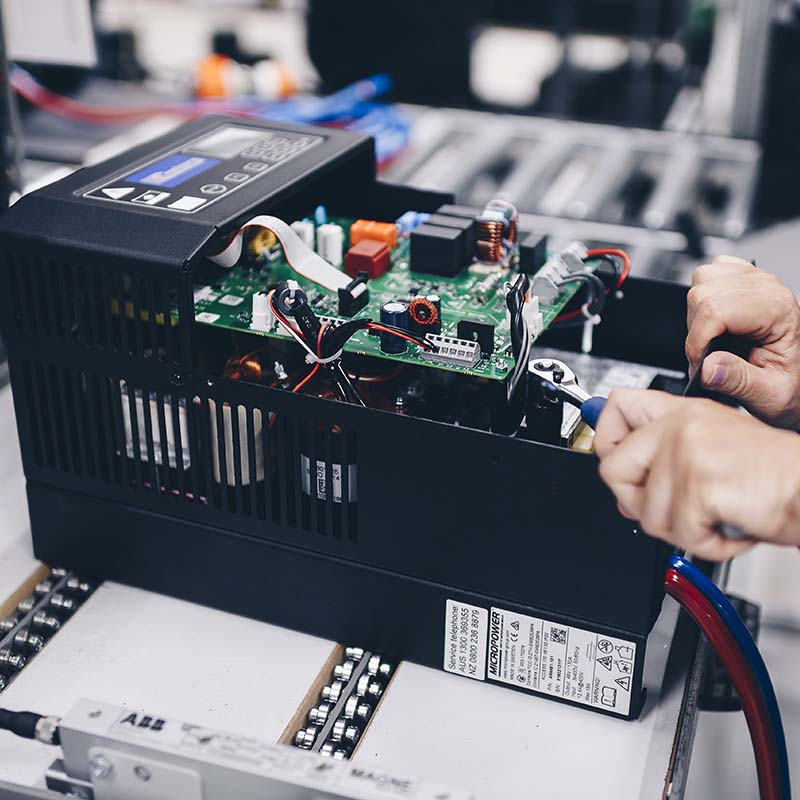

Industrial PCB Assembly – This is the stage where the necessary components are etched on the board as per the design. The steps in this process include:

-

Solder Paste Stenciling – This step involves application of solder paste to the board. The use of a stencil allows assemblers to apply solder paste only to certain parts of the PCB. With the use of an applicator solder paste is applied on the intended areas in precise amounts.

-

Pick and Place – Next, the pick and place machine places surface mount components on the PCBs. The components are then soldered to the surface of the board.

-

Reflow Soldering – This process involves moving the PCB board to a conveyor belt that moves through a large reflow oven. In turn, it melts the solder paste. The PCB next passes through coolers that allow the melted solder to solidify. This connects the surface mount components to the PCB. For two-sided PCB Assembly, the side with fewer and smaller parts is first stenciled, placed and reflowed, followed by the other side.

-

Inspection and Quality Control Once the surface mount components are soldered the assembled board needs to be tested for functionality. Common inspection methods include:

-

Manual Checks: These are particularly helpful for smaller batches where an in-person visual inspection can be carried out. This method, however, becomes impractical when the number of boards increase.

-

Optical Inspection: This method works well for large batches. An AOI machine uses a series of high-powered cameras to inspect the PCBs. Different quality solder connections reflect light in different ways allowing the AOI to detect a low-quality solder.

-

X-Ray Inspection: This method is used for complex or layered PCBs. It allows the viewer to see through layers to identify any potential problems

-

- Through-Hole Component Insertion – The board could also contain other components besides surface mount ones. A plated through-hole in this case is plated all the way through the board. Instead of soldering paste, a manual through-hole insertion is used. Wave soldering can also be undertaken where once the plated through hole component is put in place, the conveyor belt runs through a specialized oven where a wave of molten solder washes over.

-

Final Inspection and Functional Test – This step tests the PCB for its functionality. It simulates the circumstances in which the PCB will operate.

The broad difference between industrial and commercial PCB manufacturing process is as under:

- Industrial PCB manufacturing requirements typically fall under class 2 or 3 while commercial PCBs fall under class 1 or 2.

- In terms of material quality typically high Tg material is used for industrial PCBs while standard FR4 is used for Commercial PCBs.

- Industrial PCB may require balancing between heavy and normal copper weights while commercial PCBs may not.

- Consistent temperature distribution is necessary for even flow of solder during PCBA for industrial PCBs.

- Industrial PCBs need moisture protection while commercial PCBs may not.

// FREQUENTLY ASKED QUESTIONS (FAQ) Industrial PCB Assembly Frequent Questions

Simply put, these industrial PCBs are built to be used in industrial applications. They are the backbone of electronically operated equipment and need to be extremely stable and reliable so as to ensure minimal downtime.

Industrial PCBs may range in the number of layers. Besides they could be rigid, flexible or rigid-flex depending on the bespoke requirements.

Some of the applications include:

- Manufacturing Equipment

- Power Equipment

- Measuring Equipment

Industrial PCB assemblies find application in industries such as:

- Electronics

- Automotive

- Military

- Aerospace

- Construction

- Healthcare, and more

Some of the commonly used material includes:

- FR4 Fibreglass

- Teflon

- Copper

- Aluminium

- Ceramic

The key factors include:

- Quality

- Thermal Capacity

- Cost

Sure. Whether you need prototype quantities or large volumes, we are fully equipped to offer it.

Some of the factors include:

- Additional layers

- Blind and buried vias

- Lead time, and more.