// Consumer ElectronicsConsumer Electronics PCB Assembly service

// ENSURING THE HIGHEST STANDARDS OF QUALITY AND SAFETYWhy us for consumer electronics PCB

State-of-the-art facility

Stringent Manufacturing Processes

Quick turnaround time

No Volume Constraints

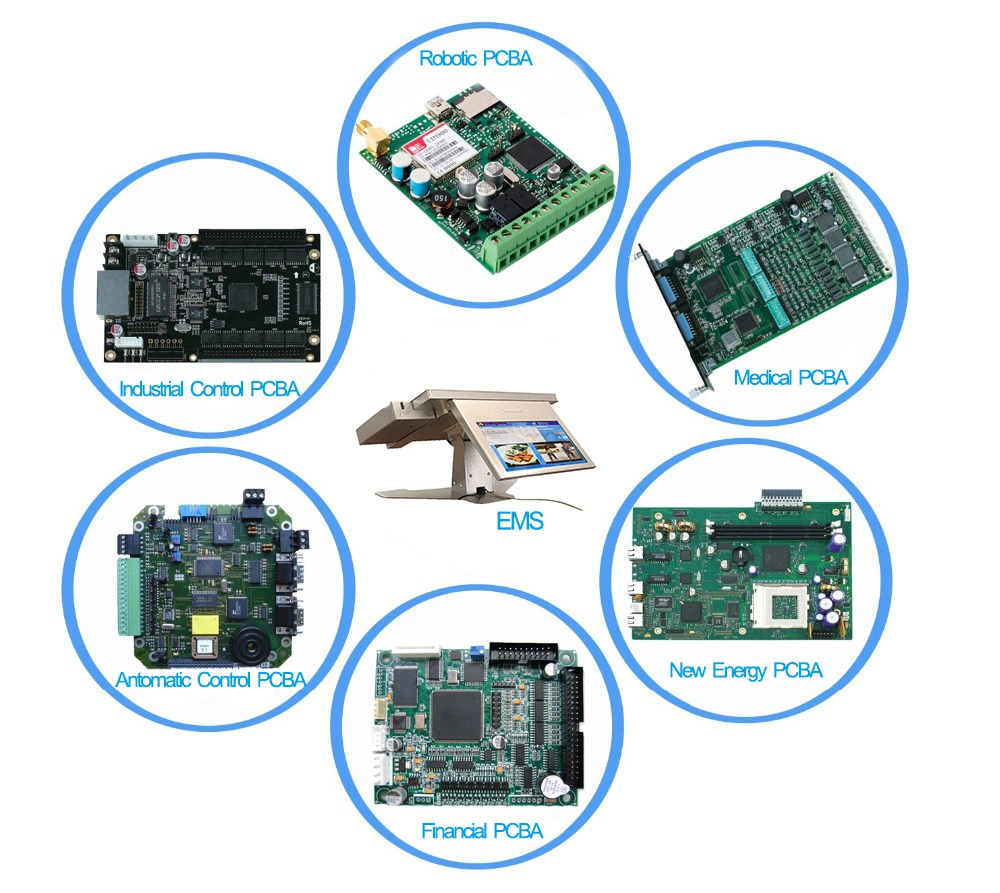

// Consumer ElectronicsConsumer electronics PCB industry applications

Audio Equipment and Systems

Consumer medical devices

Core Certification

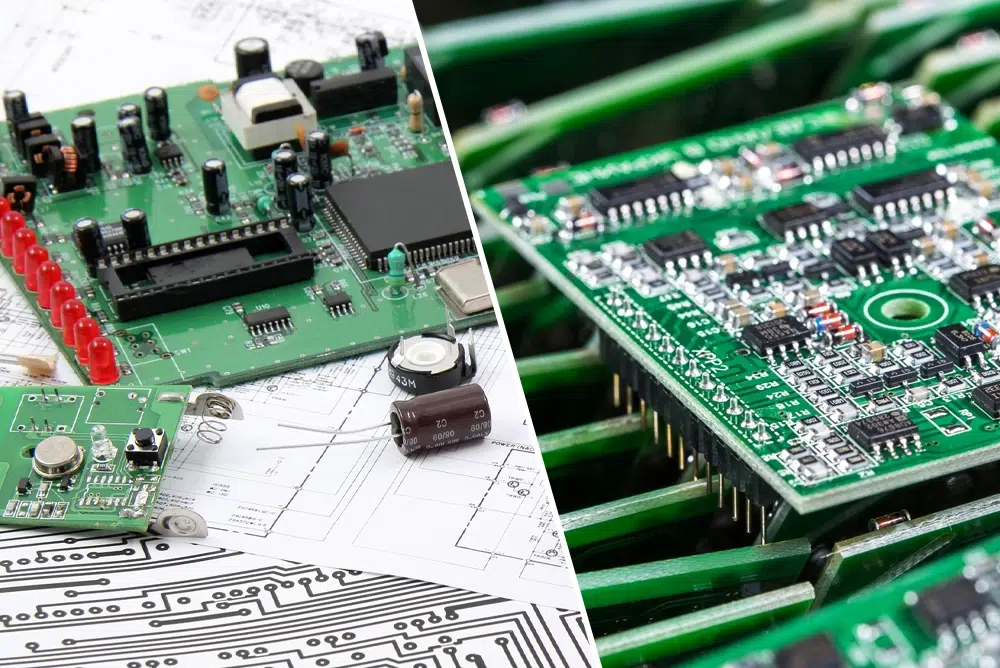

Consumer Electronics PCB Manufacturing Process

1. Electronics PCB Design and Output

To begin with, a PCB layer is created using a PCB design software by designers. Once the design is approved for production, the design is exported into a supportive format. A Design for Manufacturability test is run to ensure that the design fulfills the requirements for minimum tolerances. What follows next is the PCB printing process.

2. Printing the inner layers

The film is next printed onto a copper foil. The basic form of PCB is a laminate board whose core material is epoxy resin and glass fiber. The laminate serves as an ideal body for receiving the copper. The substrate material provides a sturdy and dust-resistant starting point for the PCB. Copper is pre-bonded on both sides. The process involves whittling away the copper to reveal the design from the films.

3. The copper

sided laminate is cleaned and the clean panel receives the photo resist layer, which hardens after exposure to UV light. The light passes through the clear parts of the film, hardening the photo resist on the copper underneath. The areas not meant to harden are then slated for removal.

4. Removing the Unwanted Copper

A powerful chemical preparation is used to eat away the excess copper. While the exposed copper is removed, the desired copper remains protected beneath the layer of photo resist.

5. Layer Alignment and Optical Inspection

The inner layers are now aligned to the outer ones. With the help of an optical punch, holes are accurately punched. An Automatic Optical Inspection is carried out to ensure absence of defects. Once the stage of inspection is passed, the PCB moves to the final stages of production.

6. Layer-up and Bond

All the layers are now fused. A prepreg layer is placed over the alignment basin. The substrate layer fits over the prepreg before placing the copper sheet. More sheets of prepreg sit on top of the copper layer. Finally, an aluminum foil and copper press plate complete the stack. Now it’s prepped for pressing.

7. Drill

Holes are now are bored into the stack board. An x-ray locator identifies the drill target spots.

8. Plating and Copper Deposition

After drilling, the panel moves onto plating. The process fuses the different layers together using chemical deposition. After a thorough cleaning, the panel undergoes a series of chemical baths.

9. Outer Layer Imaging

Photo resist is once again applied and exposed to UV light. Finally, the outer plates undergo inspection to ensure all of the undesired photo resist was removed.

10. Plating

The panel is electroplated with a thin copper layer. Etching removes the unwanted copper foil from the panel.

11. Final Etching

The unwanted copper undergoes removal. The tin protects the copper during this stage.

12. Solder Mask Application

Panels are cleaned and solder mask applied to both sides and exposed to UV light. The covered portion remains unhardened and undergoes removal.

13. Surface Finish

The appropriate surface finish is added based on bespoke requirements and based on the environment under which the electronic product has to operate. At Mer-Mar Electronics, we have a wide range of surface finishes on offer.

14. Silkscreen

The vital information pertaining to the PCB is next written on the surface.

15. Electrical Testing

Electrical tests are next performed to check functionality. At Mer-Mar Electronics, we also perform the Flying Probe Test to test the electrical performance.

16. Profiling and V-Scoring

Printed Circuit Boards are now cut from the original panel. This is done using a Router or V-Groove.

01Consumer Electronics PCB Capabilities

At KKPCB, the following are our capabilities when it comes to Consumer Electronics PCBs:

- 1 to 32+ Layers

- Leaded and lead-free printed circuit boards

- Leadless chip carriers, BGA to 12 Mil pitch, single or double sided BGAs, and passives down to 0201

- Ultra-fine pitch QFP, FCP & 0201 placement & repair, QFN, and CSP

- HASL, immersion silver, lead-free finishing: HASL, HASL + Gold fingers, OSP, ENG gold

- Rogers, FR-4, Teflon, Nelco, and Getek

- Surface Mount Assembly, Through-hole assembly, single- or double-sided SMT assembly, and mixed SMT

- X-ray inspection, Automated Optical Inspection (AOI)

- Air-conditioned and static-free work environment

- Rigid, flex, and multi-layer PCB assembly

- Wide selection of materials

- Large scale PCB assembly

- Lead free and quick turn PCB assembly

02Application of Consumer Electronics PCBs

Consumer Electronics PCBs find extensive application in a wide range of products including but not limited to:

- Wearable devices

- Stereo players

- Camcorders

- LED and Retail Lighting

- Vending Machines

- Digital Camera Systems

- Video gaming consoles

- Wired and wireless mouse

- Computer monitors

- Televisions

- Printers and fax machines

- Smartphones

- Solid State Drives

- Computers

- Tablets

// Frequently Asked Questions (FAQ)Consumer Electronics PCB Frequent Questions

The most advance trends of consumer PCB electronic products are miniaturization and diversification. There are many other trends as well including integrated circuits development, passive and discrete devices, substrate board, environmental protection awareness and more.

Yes, absolutely. We offer strong design for manufacturing services that ensure you get the best quality PCBs and you do not have to contend with costly errors.

Totally. Count on us to undertake electrical testing as also Flying Probe Testing to ensure efficacy.

You could get an instant quote on submitting your custom requirements. All you need to do is to request a quote for consumer electronics PCB and fill up the details. You could also write in to us at sales@kkpcb.com or call us at +86 13823765993 for nay clarifications. We will be happy to hear from you and offer bespoke solutions.

Yes, the choice of finish is recommended basis the environment the PCB has to work in.

Totally. We understand the importance of quick turnaround times in competitive industries such as consumer electronics and are committed to the cause.

Yes, from prototypes to full production runs, we handle it all.

Rest assured, our prices are extremely cost-effective.