//Electric / Autonomous VehiclesTop Automotive Electronics PCB Assembly Supplier

//InApplication of PCB in Automotive IndustryElectric / Autonomous Vehicles Applications

PCB Assembly

Cable & Wire Harness

Box build assembly

// SELECTING THE BEST EV SOLUTIONS SUPPLIERCharacteristics of PCB manufacturing in the automotive field

PCB manufacturing in the automotive field requires specific characteristics and considerations to meet the stringent requirements and standards of the industry. Here are some key characteristics of PCB manufacturing in the automotive field:

High Reliability

Automotive PCBs must exhibit high reliability and durability to withstand the demanding conditions and operating environments of vehicles. They should be able to withstand temperature variations, vibrations, moisture, and other harsh conditions without compromising performance.

Thermal Management

Automotive PCBs often encounter high-temperature environments, especially when located near the engine or in the vicinity of heat-generating components. Effective thermal management techniques, such as the use of heavy copper layers or thermal vias, are employed to dissipate heat and maintain optimal operating temperatures.

Design for Manufacturing (DFM)

PCB manufacturers in the automotive field employ robust Design for Manufacturing practices to optimize the manufacturability of automotive PCBs. DFM considerations involve ensuring proper component placement, optimized trace routing, impedance control, and effective signal integrity to minimize potential issues during production.

Quality Control and Testing

Rigorous quality control measures are implemented throughout the manufacturing process to ensure the reliability and performance of automotive PCBs. This includes comprehensive testing procedures, such as automated optical inspection (AOI), in-circuit testing (ICT), and environmental testing, to identify any defects or weaknesses and ensure adherence to specifications.

Robust Materials

The materials used in automotive PCB manufacturing are carefully selected to ensure resilience and longevity. High-quality substrates and laminates with excellent thermal and mechanical properties are chosen to withstand temperature extremes and provide stability in automotive applications.

Compliance with Automotive Standards

Automotive PCBs must adhere to industry-specific standards and regulations to ensure safety, reliability, and compatibility. Standards such as ITAF16949 and AECQ100 define the requirements for automotive electronic components, including PCBs, to meet the quality and performance expectations of the automotive industry.

Traceability and Documentation

Automotive PCB manufacturing requires meticulous traceability and documentation. This includes capturing and recording key information such as material sourcing, manufacturing parameters, testing results, and quality control measures. Traceability ensures transparency and facilitates investigations if necessary.

Long-term Availability

The automotive industry often relies on long product lifecycles, and therefore, PCB manufacturers in this field need to provide assurances of long-term availability and support for their products. This involves maintaining a stable supply chain, obsolescence management, and offering extended product life cycles to meet the needs of automotive manufacturers.

// FREQUENTLY ASKED QUESTIONS (FAQ)Automotive PCB Assembly Frequently Asked Questions

Automotive PCB assembly involves designing, manufacturing, and assembling PCBs for use in vehicles, ensuring high reliability, effective thermal management, and compliance with industry standards such as ISO/TS 16949. It utilizes advanced technologies such as HDI and SMT, and requires rigorous electromagnetic compatibility (EMC) and functional safety testing. These processes ensure that automotive PCBs can withstand harsh environmental conditions and meet the stringent quality and safety requirements of modern automotive electronics.

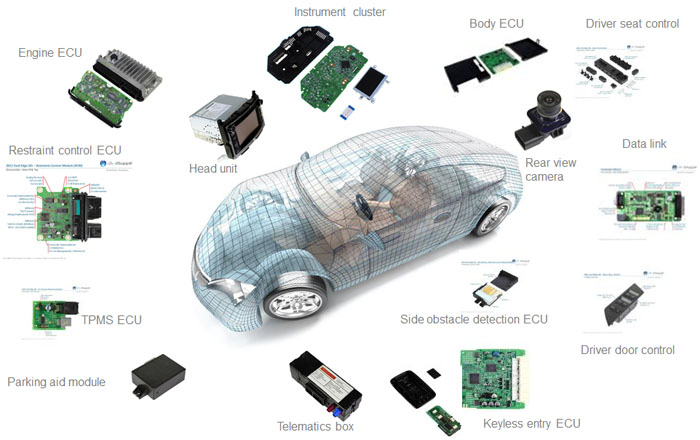

Automotive PCBs are critical to a variety of vehicle systems, including engine and transmission control, safety features, advanced driver assistance systems (ADAS), infotainment, lighting, climate control, battery management, sensor integration, telematics, power management, and instrument clusters. They enhance vehicle performance, safety, efficiency, and user experience, making them essential components in modern automotive electronics.

Automotive PCB assembly quality assurance includes adhering to standards such as ISO/TS 16949 and IPC-A-610, validating designs and processes, inspecting components, and ensuring high-quality soldering. Key practices include automated optical inspection (AOI), in-circuit testing (ICT), functional testing, and environmental stress testing to ensure reliability and performance. Comprehensive documentation, traceability, and continuous improvement processes are essential to maintaining high standards, while RoHS compliance ensures the restriction of hazardous substances. Together, these measures ensure that automotive PCBs meet stringent quality requirements for safety and durability.

Automotive PCBs are essential to modern cars, powering essential control systems, safety features, infotainment, lighting, and sensor integration. They ensure optimal performance, fuel efficiency, and compliance with safety and emissions regulations. Designed to withstand harsh conditions, automotive PCBs are critical to the reliability and durability of automotive electronic systems, making them essential for the functionality and safety of today’s cars.

Designing automotive PCBs requires special attention to reliability, durability, and thermal management to withstand harsh environments and extreme temperatures. Effective electromagnetic compatibility (EMC), mechanical stability, high component density, and compliance with industry standards are essential. In addition, signal integrity, cost optimization, and design for manufacturing (DFM) considerations ensure that the PCBs are reliable, cost-effective, and suitable for efficient production and assembly. Together, these factors ensure that automotive PCBs meet the demanding requirements of modern vehicles.

Automotive PCBs feature high reliability, effective thermal management, robust materials, electromagnetic compatibility, miniaturization, compliance with safety standards, environmental resistance, use of advanced technology, multi-layer design, and focus on functional safety. These features ensure that PCBs can meet the demanding requirements of automotive applications and provide reliable and durable performance in a variety of vehicle systems.

In the automotive industry, PCB assembly includes surface mount technology (SMT), through-hole technology (THT), hybrid technology, flexible PCB, rigid-flex PCB, high-density interconnect (HDI) PCB, metal core PCB, and double-sided or multi-layer PCB. The choice of these methods depends on the specific requirements for reliability, durability, and performance of various applications such as engine control units, infotainment systems, safety features, and high-power applications such as LED headlights.