// IoT and WearablesIoT and Wearables PCB Assembly service

The Internet of Things (IoT) is revolutionizing our modern world, connecting devices across smart homes, wearable technology, industrial automation, smart cities, and beyond, to deliver greater convenience, personalization, safety, sustainability, and operational efficiency. By enabling seamless communication, real-time data collection, and intelligent analysis, IoT simplifies daily routines, automates complex tasks, and provides tailored experiences across multiple sectors. As a leading specialist in IoT electronics manufacturing, KKPCB offers comprehensive PCB assembly, design, prototyping, and full-scale production solutions for IoT and wearable devices. Leveraging advanced high-reliability PCB technologies, including HDI, flexible PCBs, and high-frequency circuits, we ensure that every product meets the highest standards of quality, performance, and durability. Our turnkey solutions, combined with rigorous quality control, rapid prototyping, and DFM support, empower customers to bring innovative IoT products to market efficiently and reliably. With KKPCB, businesses can create smarter, safer, and more connected devices that enhance lives and drive the next generation of IoT innovation.

// IoT PCB SolutionsApplications of PCB for the Internet of Things (IoT)

// KKPCB Rapid SMT Assembly ServiceFeatures of Our IoT PCBs

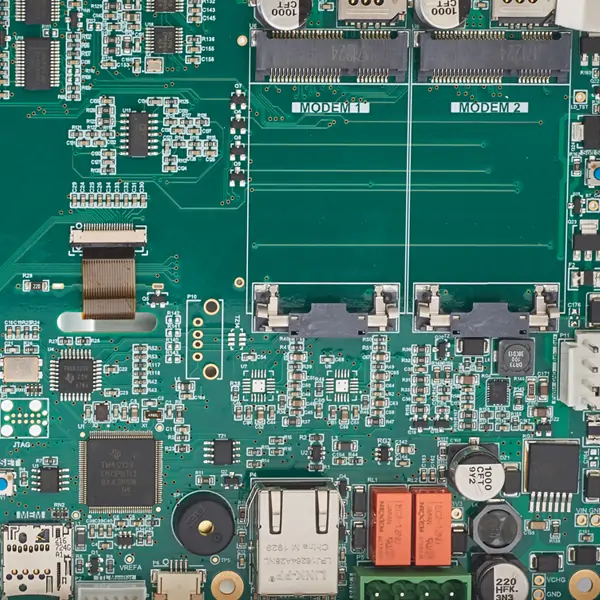

Multifunctional:

IoT PCB can accommodate and integrate a variety of sensors, signal processing, communication and data storage devices, supporting various types of data acquisition and processing.

Space saving:

IoT PCB adopts compact design, which can put more components and functions on a small size circuit board.

Low cost:

The manufacturing cost of IoT PCB is relatively low because it can integrate multiple components and functions on a small circuit board, which reduces the manufacturing cost.

High performance:

IoT PCB adopts high-precision, high-speed and high-density circuit design, which provides faster data transmission speed, lower power consumption, higher reliability and larger capacity.

Customizable:

IoT PCB can be customized according to customer needs to meet the requirements of various application scenarios.

Highly integrated:

IoT PCB has higher integration and diversified functions, which can realize more efficient data collection and processing, and is an important part of IoT devices.

In the field of the Internet of Things, IoT PCBs play a critical role in enabling smart, connected devices across a wide range of applications. As IoT devices become more prevalent and the number of application scenarios grows, the importance of reliable and high-performance IoT PCBs continues to increase.

Connecting devices: IoT PCBs serve as the backbone for connectivity, allowing various IoT devices to communicate seamlessly, share information, and operate in a coordinated manner.

Data acquisition and processing: By integrating multiple sensors and data acquisition modules, IoT PCBs enable real-time monitoring and processing of environmental, location, temperature, humidity, pressure, and other data, supporting intelligent decision-making.

Remote control and automation: IoT PCBs empower remote control capabilities, enabling users to operate smart home systems, industrial machinery, or wearable devices through smartphones, computers, or cloud platforms.

Support for big data and analytics: Advanced IoT PCBs can handle large volumes of data, feeding into analytics systems to optimize operations, predict maintenance needs, and enhance performance.

Improving production efficiency and quality: In industrial applications, IoT PCBs allow equipment to monitor and analyze data continuously, automate processes, and implement optimization strategies, resulting in higher production efficiency, better product quality, and reduced downtime.

By combining high reliability, precision engineering, and advanced PCB technologies, IoT PCBs provide the foundation for intelligent, data-driven, and highly efficient IoT systems, enabling businesses and consumers to unlock the full potential of connected devices.

// WHY CHOOSE US ?Why Choosing KKPCB For Your IOT PCBs

High Quality

Customized services

Fast Delivery

Affordable

Professional Technical Support

Reliability Guarantee

// FREQUENTLY ASKED QUESTIONS (FAQ)Internet of Things (IoT) PCB

Frequent Questions

An Internet of Things (IoT) PCB is a specialized printed circuit board designed to enable connectivity and functionality in smart devices. It features compact, energy-efficient designs with integrated communication modules and sensors, robust construction for varying environments, and security measures to protect data. IoT PCBs are essential for applications across smart homes, wearable technology, industrial automation, agriculture, and healthcare, facilitating devices that collect, transmit, and receive data over the internet.

IoT PCBs are used in a variety of applications such as smart home devices, wearables, industrial automation, agriculture, healthcare, smart cities, retail, and logistics. They enable connectivity, real-time data collection, and automation, enhancing efficiency and functionality in these sectors. IoT PCBs facilitate remote control, monitoring, and optimization of systems, driving innovation and improving operational performance across diverse industries.

Quality assurance for IoT PCBs involves ensuring that designs meet specifications, components are high-quality, and manufacturing processes adhere to standards. Key aspects include verifying soldering quality, using automated optical inspection (AOI), conducting in-circuit and functional testing, and performing environmental and stress tests. Compliance with electromagnetic compatibility (EMC) and electromagnetic interference (EMI) standards, security measures, traceability, and continuous improvement processes are also essential to ensure the reliability, performance, and safety of IoT devices.

In IoT PCB design, crucial factors include ensuring connectivity with various communication protocols, optimizing for low power consumption, and accommodating compact sizes. Effective thermal management, signal integrity, and mechanical durability are essential for reliable operation. Environmental resistance, compliance with standards, and incorporation of security features are also critical. Additionally, planning for comprehensive testing and ensuring scalability and flexibility for future upgrades are important for creating robust and adaptable IoT devices.

Internet of Things (IoT) PCB assembly types include Surface-Mount Technology (SMT) for high-density designs, Through-Hole Technology (THT) for robust connections, and Mixed Technology for combining both methods. Flexible PCBs offer adaptability for space-constrained designs, while Rigid-Flex PCBs provide a balance of rigidity and flexibility. Hybrid PCBs integrate traditional materials with advanced technologies for specialized functions. Each type is selected based on the specific needs for component density, flexibility, durability, and integration in IoT devices.

IoT PCB products are essential because they enable connectivity and integration in smart devices, enhancing their functionality and efficiency. They facilitate data collection and analysis, improve user experiences, and drive innovation across various sectors. Additionally, IoT PCBs support scalable, adaptable designs and incorporate security features to protect against cyber threats, making them crucial for the advancement and effectiveness of IoT applications.

For Internet of Things (IoT) PCB assembly, essential files include Gerber files for layout details, Bill of Materials (BOM) for component specifications, pick and place files for accurate component placement, and assembly drawings for visual guidance. Stencil files are needed for solder paste application, while design files provide the electrical and physical layout. Additionally, test plans ensure proper functionality and quality, fabrication drawings detail manufacturing specifications, and material specifications confirm the required performance standards. These files collectively ensure precise production, accurate assembly, and reliable performance of IoT PCBs.