//High-Performance Aerospace PCB AssemblySatellite and Aerospace PCB Assembly

There is a rapidly growing demand for high-performance printed circuit boards (PCBs) in the aerospace, aviation, and satellite industries. These sectors are always at the cutting edge of technology, where safety, reliability, and innovation are mission-critical. At KKPCB, we have invested in advanced manufacturing technologies, modern facilities, and an expert engineering team to deliver precise, high-tolerance, and aerospace-grade PCB assemblies that meet the most demanding requirements.

As a trusted aerospace PCB assembly manufacturer, we understand the stringent engineering and quality standards that govern this industry. Aerospace electronics must withstand extreme operating conditions such as:

-

Severe temperature fluctuations

-

High levels of vibration and mechanical shock

-

Humidity, moisture, and dust exposure

-

Solar radiation and harsh environmental stressors

Since repairing or replacing aerospace PCBs in-flight or in orbit is often impossible, each assembly must be designed and manufactured with absolute reliability and uncompromised performance in mind.

At KKPCB, we achieve this through:

-

Aerospace-grade manufacturing processes compliant with IPC, AS9100, and military standards

-

Rigorous quality control and traceability at every production stage

-

Custom engineering support to optimize designs for manufacturability and reliability

-

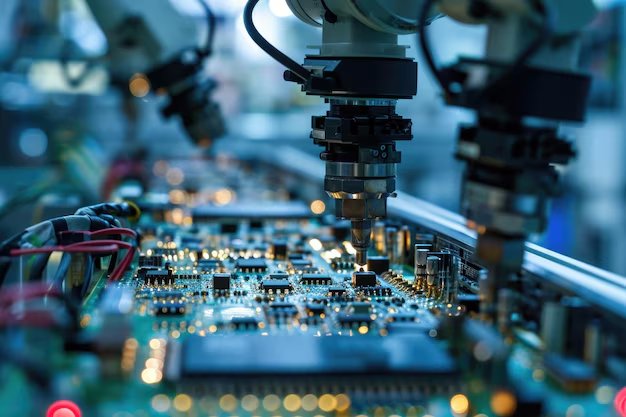

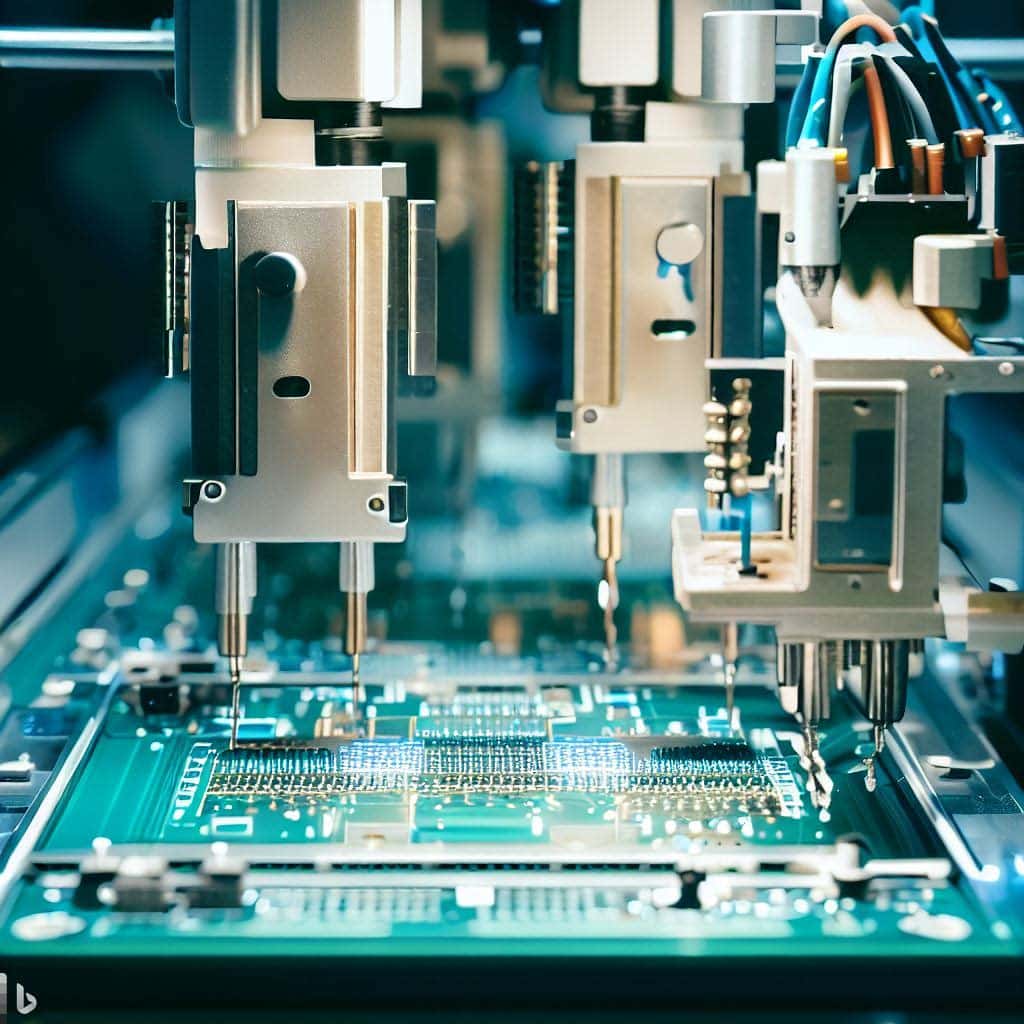

Cutting-edge equipment to ensure precision, consistency, and scalability

From initial design and prototyping to small-batch runs, mass production, and turnkey delivery, KKPCB provides end-to-end Aerospace Electronics Manufacturing Services (EMS).

With more than 10 years of proven expertise, a state-of-the-art in-house facility, and a track record of supporting aerospace and defense OEMs worldwide, KKPCB has earned a reputation as one of the most reliable partners for aerospace PCB manufacturing and assembly.

Whether you require rigid, flexible, or rigid-flex PCBs for avionics, satellites, communication systems, or mission-critical aerospace equipment, KKPCB delivers tailored solutions that ensure safety, stability, and long-term performance in the harshest environments.

//AEROSPACE ELECTRONICSApplications of PCB for Aerospace Electronics

PCB Assembly

Cable & Wire Harness

Box build assembly

Our Aerospace PCB Assembly Capabilities

Our range of aerospace printed circuit board assembly designing and manufacturing capabilities includes:

- Aerospace rigid flex circuit and assembly

- Aerospace flexible circuits

- Wide material selection

- Advanced and cutting-edge technology

- Quick turn aerospace printed circuit boards

- Latest and advanced process & manufacturing

- Small, medium and large-scale manufacturing and EMS capabilities

- Aerospace Product Development and Prototyping

- Industrial design

- Mechanical design

- Rapid Prototyping

- 3D Additive manufacturing

- Design for manufacturability

- NPI (New product introduction)

- Failure analysis

Aerospace Printed Circuit Board Assemblies Characteristics

- The aerospace & aviation industry requires more solid printed circuit board assemblies than normal device. We manufacture circuit boards for aerospace with extreme precautions and with extra durable materials. We have implemented advance PCB assembly technologies which benefits to make it safer, secure and efficient.

- We utilize high temperature laminates, copper, and aluminum materials in aerospace printed circuit board assembly; so that they can survive utmost temperature conditions!

- Printed circuit boards and electronics used in the aerospace industry can also be exposed to mechanical abuse like excessive shock and vibration. We have implemented few processes to make Aerospace PCB assemblies and circuit boards safer & secure against vibrations and shock.

- As a leading PCB manufacturer, we attempt to shield electronics from radiation using various materials. We made circuit boards more resilient by using thinner layers of material.

- We ensure the radio communications are transmitted correctly.

- The prevailing mounting technologies known in the aerospace printed circuit board assemblies are through hole and surface mount technology.

We are among proactive solution provider of Aerospace printed circuit board assemblies. We deliver full suite of value-added electronics manufacturing services from layout, design, integration, PCBA and full production run for the aerospace, military, aviation, commercial and other market.High-Performance Aerospace PCB Assembly. We are AS9100 Rev D Certified and ITAR Registered Aerospace Electronics Provider!

// Frequently Asked Questions (FAQ)Aerospace PCB Assembly

Frequent Questions

Aerospace PCB assembly is the process of connecting electronic components with printed circuit boards which are widely used in Aerospace or Aviation industries! We provide aerospace PCB assemblies with greater control and no errors.

We have a well defined and documented quality management system to ensure the quality of aerospace PCB assemblies. Furthermore, our manufactured range of aerospace PCBs go through the triple inspection process! Feel free to contact us if you have any requirements!

We would take 24 hours to 4 days for small production run to prototypes and 5-10 days for medium to large printed circuit board production. Although, the time may depend on various factors including material availability, complexity, quantity of requirements! Feel free to contact us or email us sales@kkpcb.com & we will get back to you with quotation and estimated time.

The different types of aerospace circuit boards include rigid, flex, rigid-flex, high density interconnects, single sided, double sided, multilayer, metal core, complex and many more. Get a quick quote based on your custom requirements!

- Mermar Electronics is ISO 9001:2015 and AS9100 Rev D Certified.

- We are also ITAR and EAR registered company.

- We have a team of experts who adheres strictly to the standards of IPC-A-610.

- In the prime business of PCB assembly, most of our assembly work is to class 3 of this standard.