Final Quality Control (FQC)

KKPCB is your trusted partner for PCB manufacturing and assembly. Beyond providing friendly service and on-time delivery, we are committed to producing high-quality PCBs and PCBA solutions that consistently meet or exceed customer expectations.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Manufacturing Standards

Quality Control Process

Quality Reports & Certifications

Raw Material Download

Manufacturing Standards

PCB Standards

| Item | Advanced PCB | Standard PCB |

|---|---|---|

| Engineering | One file/1 day + Senior Engineer | Mid-level Engineer (1 file/hour) |

| Material | Shengyi, Rogers, Arlon, Isola, Omega, Nelco, 3M, etc. Compliant with Class B/L IPC4101 | KB (Kingboard) / GDM (Goldenmax) Compliant with Class B/L IPC4101 |

| Inks & Solder Mask | Rohm&Haas, TAIYO, Kuangshun, Compliant with Class T IPC-SM-840 | TAIYO, Kuangshun, Compliant with Class T IPC-SM-840 |

| Drilling | Min. mechanical hole size 0.15 mm, laser hole 0.1 mm | Min. mechanical hole size 0.2 mm |

| Plating | PTH (copper thickness in hole ≥20 μm), IPC 3 (25 μm) | PTH (copper thickness in hole ≥18 μm) |

| Solder Mask Offset | ±2 mil | ±3 mil |

| Dimensional Tolerance | ±0.13 mm | ±0.2 mm |

| Warp Angle | 0.75% | 1% |

| Testing Method | A.O.I, 4-wire Kelvin measurement, microsection, solderability test, impedance test... | A.O.I., flying probe testing, fixture testing |

| Glass Transition Temperature ℃ | >140℃ | >130℃ |

| Trace Etching | Repairing traces is prohibited (IPC 3, Automotive standard, Customer standard) | – |

| Cleanliness | Higher cleanliness requirements than IPC | Higher cleanliness requirements than IPC |

PCB Assembly Processing Capability

| Parameters | Capabilities for Bulk Orders | Capabilities for Trial Orders |

|---|---|---|

| Board Size | L50×W50mm ~ L510×W460mm | No restrictions |

| Board Thickness | T=0.4~4.0mm | No restrictions |

| Min. SMD Size | 01005 (inch) | 01005 (inch) |

| Max. SMD Size | 45×45mm (connector length: 150mm) | No restrictions |

| Min. IC Pin Pitch | 0.3mm | 0.3mm |

| Min. BGA Ball Pitch | 0.4mm | 0.4mm |

| Equipment Placement Accuracy | ±0.35mm @3σ | ±0.35mm @3σ |

| SMD Production Capacity | 1,000K points/day | 200 orders/day |

| DIP Production Capacity | 500K points/day | 200 orders/day |

// Perfect quality systemQuality Control Process

PCB Quality Control Process

Our PCB Quality Control Process Includes:

- Verifying PCB laminates, copper foils, and solder masks for thickness, dielectric properties, and surface integrity.

- Ensuring compliance with RoHS, REACH, and UL safety and environmental regulations.

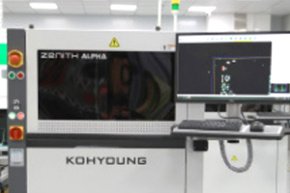

- Performing Automated Optical Inspection (AOI) to detect alignment errors, etching defects, and surface contamination.

- Verifying copper thickness uniformity and ensuring high-precision trace formation.

- Using X-ray drilling alignment verification to ensure accurate via placement.

- Conducting plating thickness measurements to meet conductivity and durability requirements.

- Checking for uniform coverage, adhesion strength, and proper curing to prevent delamination.

- Ensuring accurate legend printing for component identification.

- Conducting Flying Probe & Bed-of-Nails Testing to detect shorts, open circuits, and resistance variations.

- Ensuring signal integrity and impedance control for high-speed PCB applications.

- Performing thermal shock, humidity resistance, and mechanical stress tests for enhanced reliability.

- Ensuring every PCB meets IPC-A-600 Class 2 & Class 3 quality standards.

At KKPCB, we are committed to zero-defect PCB manufacturing, delivering high-performance, high-reliability circuit boards for applications in automotive, aerospace, medical, and industrial electronics.

PCB Assembly Quality Control Process

At KKPCB, we implement a strict, multi-step PCB assembly quality control process to guarantee that every assembled PCB meets the highest industry standards for precision, durability, and functionality. By utilizing advanced inspection technologies, rigorous testing protocols, and certified quality management systems, we ensure zero-defect production and long-term reliability for industries such as automotive, aerospace, medical, industrial, and consumer electronics.

KKPCB has dozens of SMT production lines. Advanced production equipment, strict quality control and intelligent service system to ensure the standardization and best quality of each production process.

Smart management system & Advanced production and testing equipment:

- Verifying PCB bare boards, components, and solder paste for conformity with specifications (RoHS, REACH, UL, IPC standards).

- Using X-ray fluorescence (XRF) and material traceability systems to ensure component authenticity and quality.

- Ensuring precise solder paste volume, thickness, and alignment to prevent defects like bridging and insufficient soldering.

- Using automated SPI systems to detect inconsistencies before placement.

- Identifying misaligned, missing, or incorrect components during placement.

- Checking for cold solder joints, insufficient solder, or bridging after reflow soldering.

- Detecting voids, solder balling, and hidden defects in BGA, QFN, and other leadless packages.

- Ensuring proper solder joint formation and connectivity.

- Checking for open circuits, shorts, incorrect component values, and solder joint integrity.

- Ensuring electrical connectivity and proper signal transmission.

- Simulating real-world operating conditions to verify board functionality.

- Testing power-up, microcontroller programming, signal integrity, and load performance.

- Conducting burn-in testing, thermal cycling, humidity resistance, and mechanical stress testing for mission-critical applications.

- Ensuring compliance with IPC-A-610 Class 2 & Class 3, ISO 9001, IATF 16949, and other industry standards.

Quality checking process and description

Assess and inspect the particularity of the PCBA manufacturing process in advance, guide the production, and improve the quality from the process technology.

● Check whether the resistance and capacitance values are correct

● Check whether the pads on the components and the board are consistent

● Confirm whether the incoming quantity is accurate

● Check whether the components are abnormal

SPI can detect whether the solder paste is sufficient and uniform, which can effectively prevent production quality problems in advance caused by poor solder paste printing.

The AOI can detect the wrong solder, reverse solder, false solder, empty solder, incomplete solder, short circuit, offset, tombstone, etc. after reflow soldering. And it can also detect excessive solder, less solder, continuous solder and other undesirable phenomena in the appearance of PCBA solder joints.

Combined with Gerber, BOM and coordinate files, the resistance and capacitance in the completed PCBA are verified again by the first-sample tester to ensure the correctness of all parameter values.

According to the IPC610D standard, inspect the soldered surface mount PCBA for errors, omissions, and false connections.

Inspect the solder joints of invisible components to ensure the reliability of each solder ball of the BGA.

Refers to the standard IPC–610 inspection standard, and the finished board is visually inspected to ensure 100 % Good products shipped.

// Our Quality CertificationsQuality Certifications

Thanks to the materials used and advanced technology, we always ensure highest quality of our printed circuit boards!

KKPCB can provide customers with certifications in various markets, such as: EU RoHS certification, EU CE certification, US UL certification, US FCC certification, Australia SAA certification, Australia C-tick certification, Australia RCM certification, Japan PSE certification, Brazil INMETRO certification, Mexico NOM certification, Canadian IC certification, Korea lithium battery KC certification, Argentina IRAM S-mark certification, DLC certification, GS certification, CB certification, etc.