// DFA/DFM SolutionWe provide 40-point DFM check

Signal Testing

Solder Mask Inspection

Training Verification

Aircraft Inspection

Silk Screen Checks

Trace Width

Spacing / Clearance

Annular Ring

Drill to Copper / Via-to-Copper Drilling

Hole Registration

Text Features

Missing Copper

Connectivity / Net Connectivity

Missing Holes

Unconnected Traces / Floating Lines

Solder Mask Clearance

Solder Mask Coverage

Mask-to-Trace / Trace-to-Mask Clearance

Spacing / Clearance

Missing Solder Mask Clearance

Exposed Traces / Open Lines

Partial Clearances

Hole Size

Duplicate Holes

Hole-to-Hole Spacing

Touching Holes

Plane Shorts

Milling Holes

Missing Holes

Drill to Copper

Annular Ring

Spacing

Trace Width

Thermal Relief Clearance

Spoke Width

Missing Copper

Copper Trace Path

Pad Registration

Clearance Less Than Hole

Silkscreen-to-Mask Clearance

Silkscreen-to-Copper Spacing

Silkscreen-to-Hole Spacing

Silkscreen-to-Trace Spacing

Line Width

Text Height

Silkscreen Over Copper Text

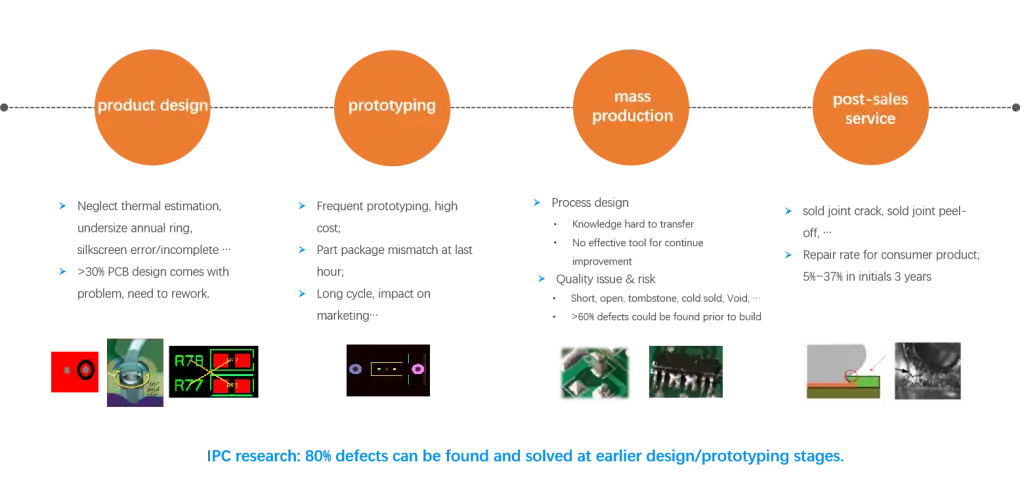

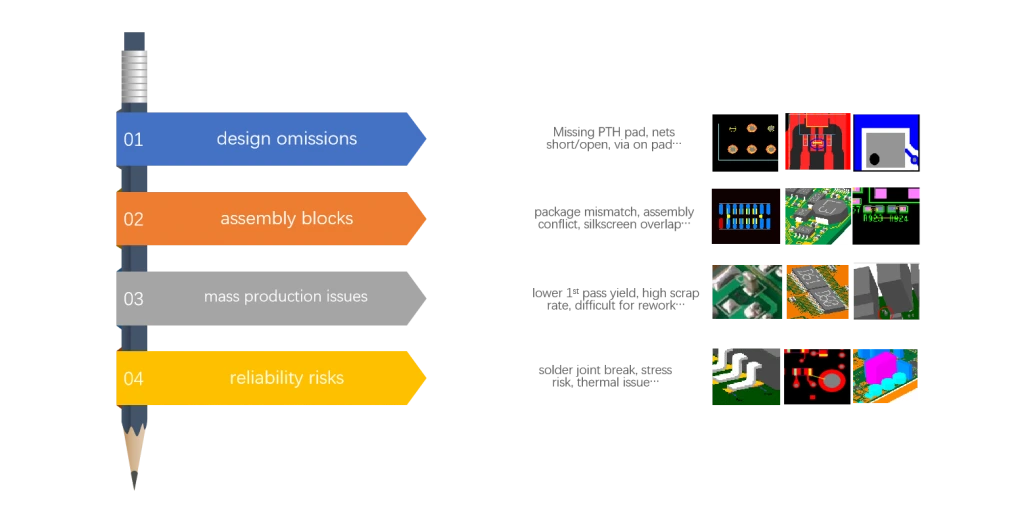

PCBA: Small Issue, Huge Impact

PCBA (Printed Circuit Board Assembly) is the kernel for most of products, it’s quality/reliability brings huge impact to our daily lives (accidents or disasters); finally it will leads to financial lost of our business.

Small issues like cracked solder joints can lead to PCBA failure

Malfunction PCBA may cause accidents, or disasters to our daily lives.

Finally it will lead to customer complain,compensation, business lost.

Enough For These Headaches?

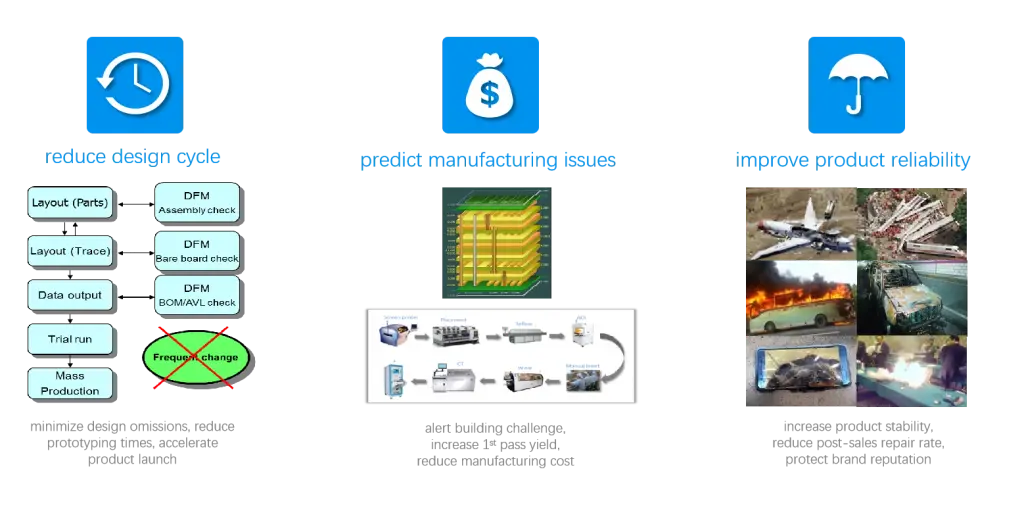

Transform With PCB/PCBA DFM

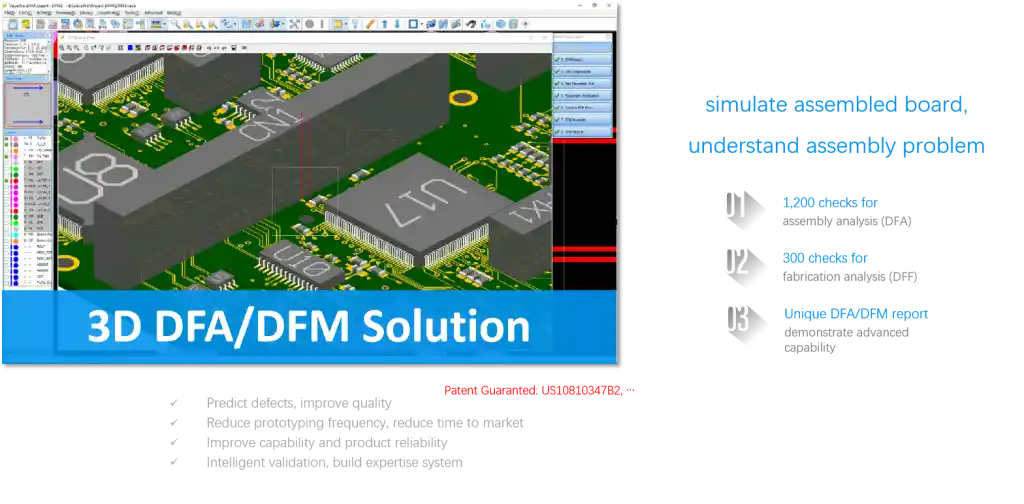

DFM Expert: Intelligent DFA/DFM Analysis

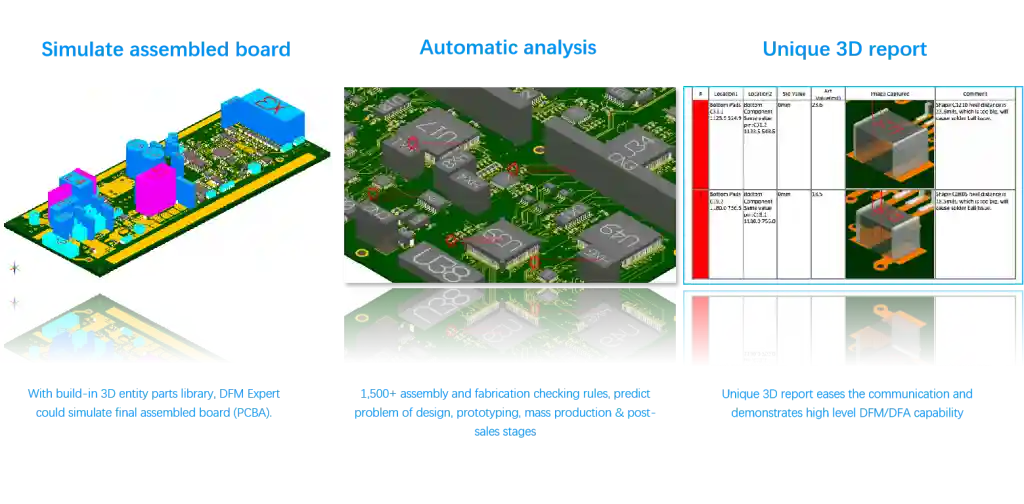

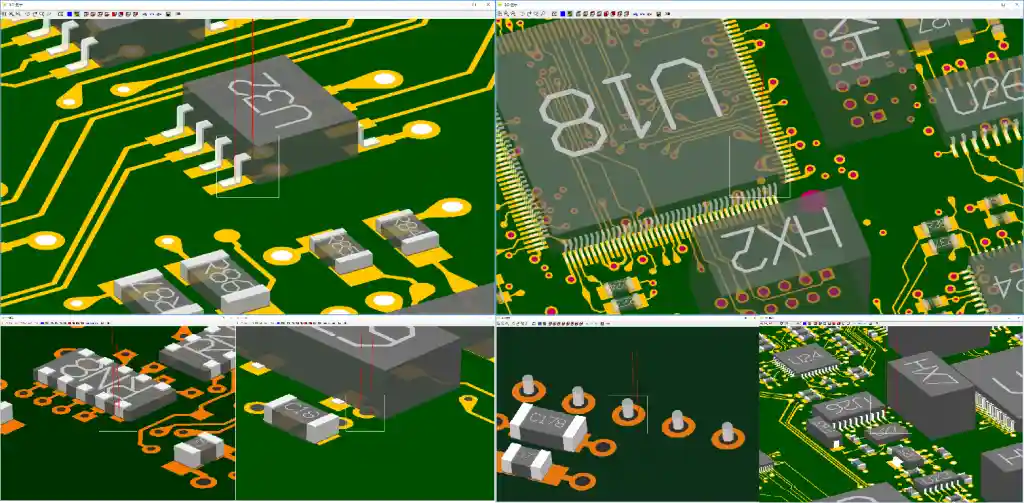

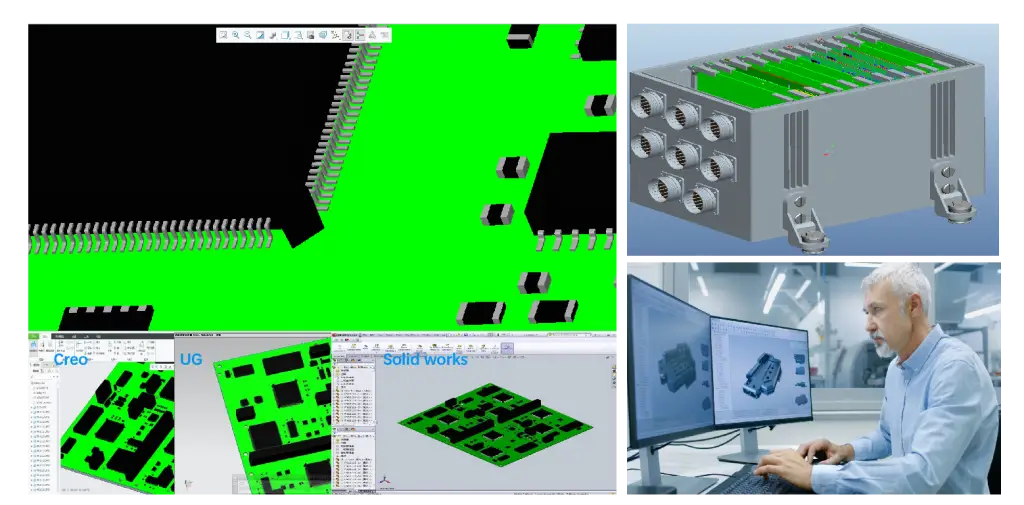

3D DFM/DFA Methodology

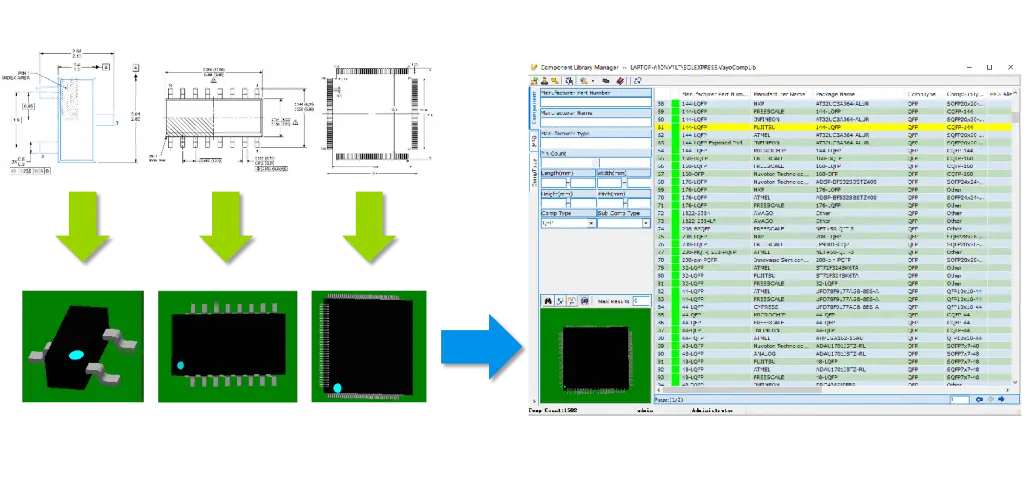

PCBA Virtualization: 3D Parts Package Library

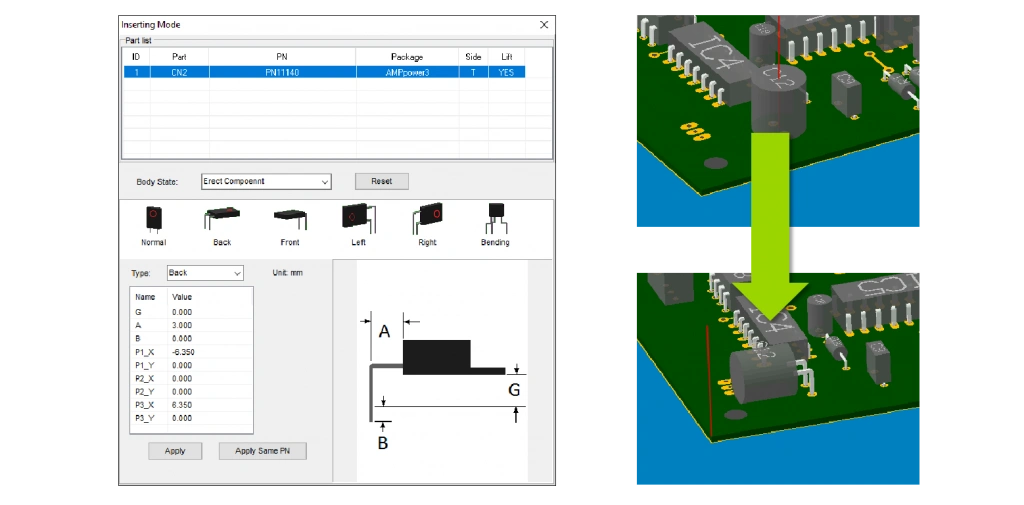

PCBA Virtualization: Reform Pin Shape

PCBA Virtualization: See Every Detail Of PCBA

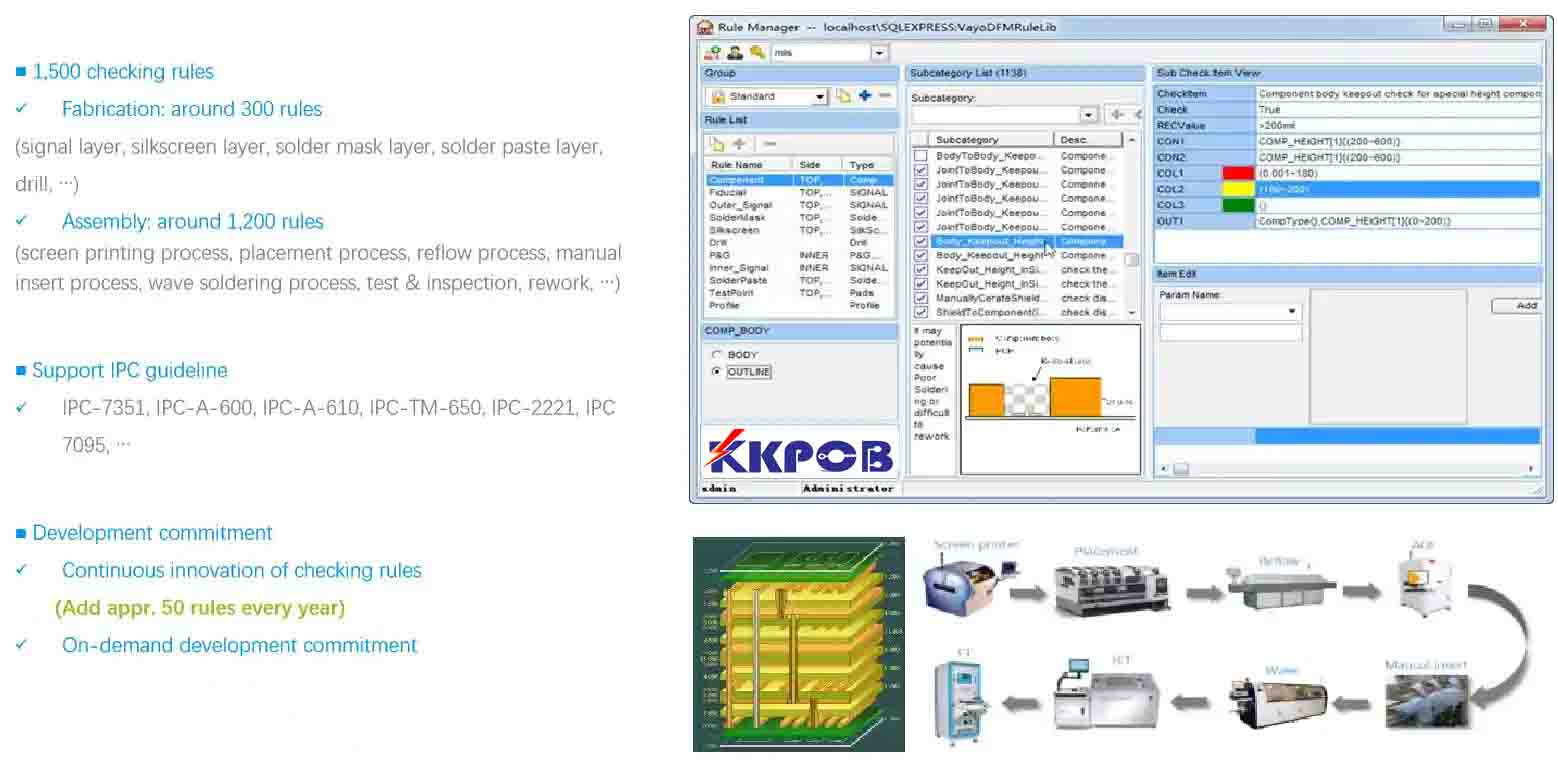

Automatic Analysis: 1,500+ Checking Rules

Automatic Analysis: Unveil Problems

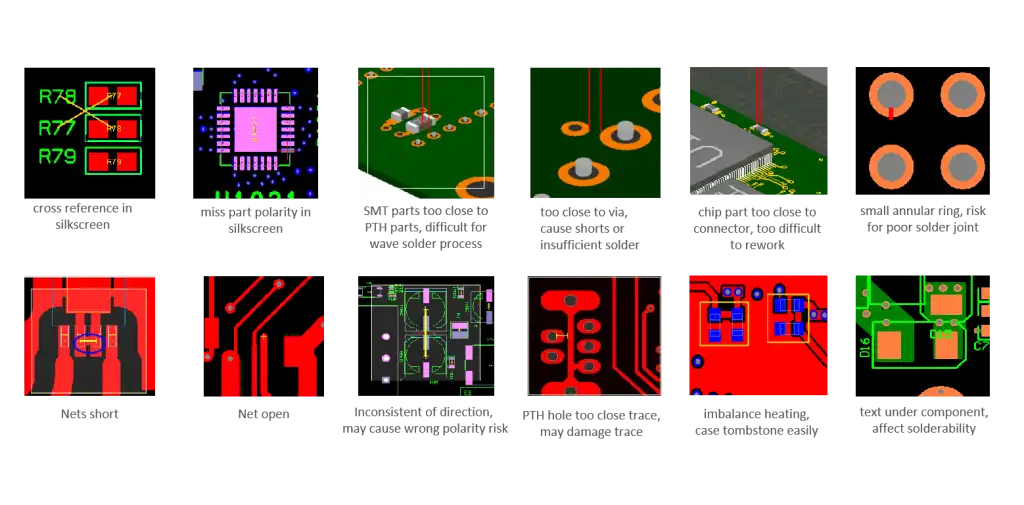

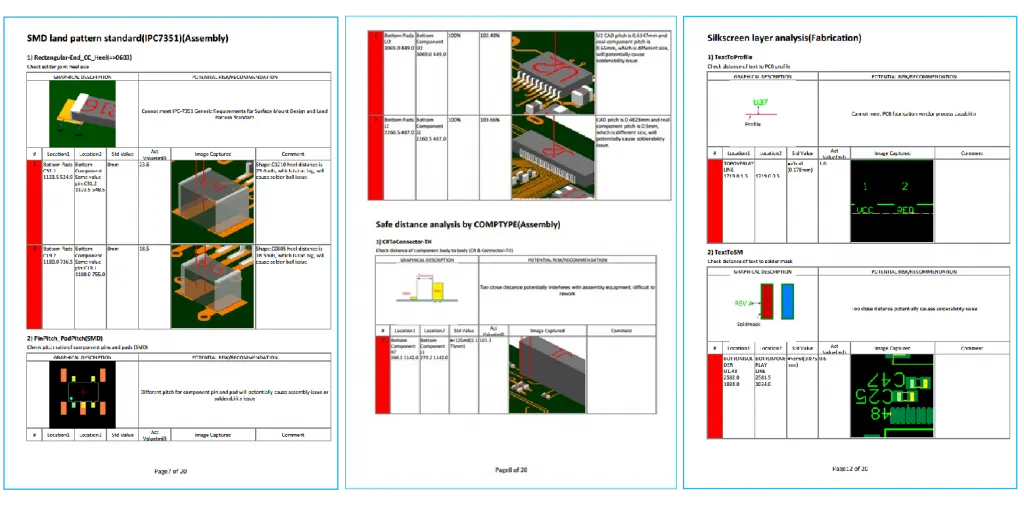

Automatic Analysis: Sample Issues

Unique 3D Report: Automatic Generation

Unique 3D Report: Communication Boost

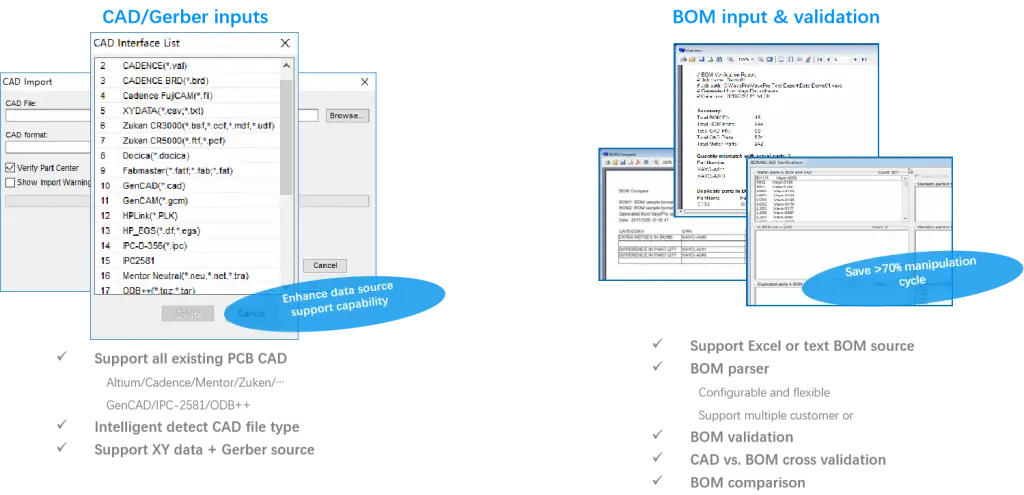

Other Features: Support CAD/Gerber/BOM Data Source

Other Features: Support CAD/Gerber/BOM Data Source

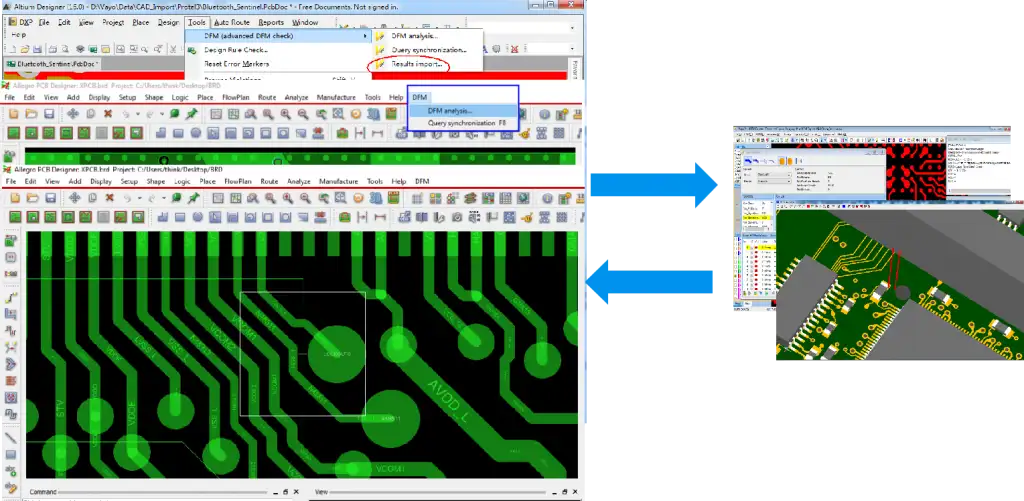

Other Features: Integrated To EDA Tools (Cadence, Altium)

Other Features: Seamless Transfer To MCAD

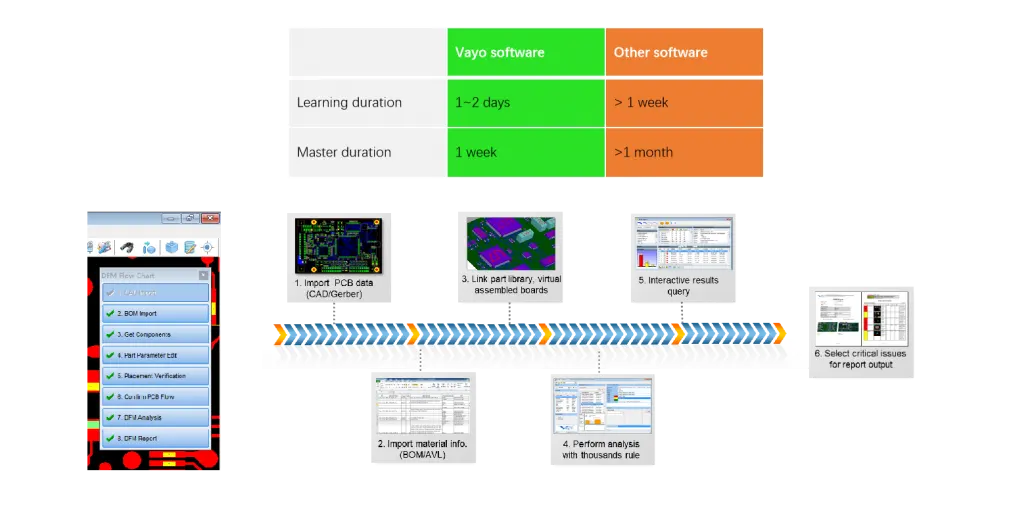

Easy To Use, Less Learning & Master Curve