// Industries We ServeKKPCB – Your One-Stop Full-Cycle PCB & PCBA Partner

one-stop provider of PCB manufacturing and assembly solutions

INDUSTRIAL CONTROL

KKPCB provides high-quality PCB and PCBA solutions for industrial control systems, including automation equipment, monitoring devices, and process control electronics.

INTERNET OF THINGS (IOT)

KKPCB provides PCB and PCBA solutions for smart agriculture IoT devices, including sensors, monitoring equipment, and automated control systems.

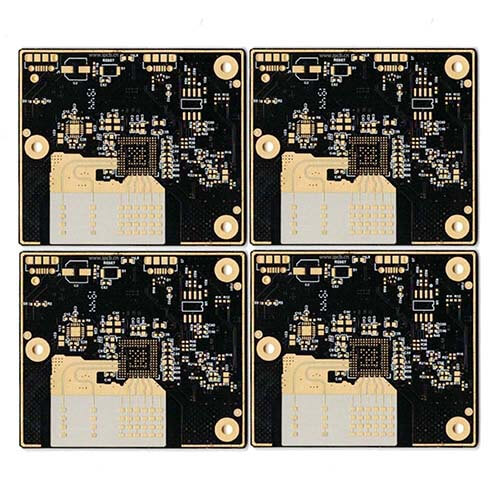

// PRODUCT SHOWCASEPCB Manufacturing and PCB Assembly

INDUSTRY SOLUTIONS – FREQUENTLY ASKED QUESTIONS (FAQ)

Automotive, telecommunications, industrial control, IoT, smart home, medical electronics, new energy, smart agriculture, aerospace, and consumer electronics.

Yes, we specialize in high-layer (up to 72 layers), high-frequency, HDI, flex-rigid, and ATE test PCBs for demanding applications.

Yes, including PCB design, prototyping, component sourcing, manufacturing, assembly, testing, and final shipment.

FR4, high-frequency materials, Rogers, Megtron, flex-rigid, HDI, BGA, QFN, micro-via, laser-drilled vias, and more.

All products undergo strict quality control and comply with IATF16949, ISO9001, UL, RoHS, and REACH standards.

Yes, we handle prototypes, small batch, and medium-volume production with flexible solutions.

Yes, we assemble BGA, Micro-BGA, QFN, and other leadless package components.

Yes, we assemble BGA, Micro-BGA, QFN, and other leadless package components.

- PCB manufacturing

- PCB Assembly

- PCB Design

At KKPCB, we maintain a comprehensive inventory of PCB materials to meet diverse customer requirements, including KB, Shengyi, Iteq, Nanya, Rogers, Isola, Arlon, Taconic, Ventec, Dupont, Tellon, Panasonic, Berquist, and more.

Our expert team specializes in high-quality PCB manufacturing, covering a wide range of boards such as multilayer PCBs, rigid PCBs, flexible PCBs, rigid-flex PCBs, thin and ultra-thin PCBs, high-frequency PCBs, and ATE test boards. Leveraging advanced equipment and industry-leading processes, KKPCB delivers custom PCB solutions with consistent quality, on-time delivery, and competitive pricing for clients worldwide.

We are committed to strict quality control, conducting thorough inspections at every stage of production to ensure that all PCBs meet IATF16949, ISO9001, UL, RoHS, and REACH standards. Our dedication to excellence has earned KKPCB a trusted reputation among global customers, making us a reliable partner for high-precision and high-performance PCB manufacturing projects.

KKPCB is equipped with state-of-the-art manufacturing equipment and advanced technologies, including 8 fully automated high-speed SMT lines, 4 DIP insertion lines, 2 ICT/FCT testing lines, and 4 box-build assembly lines.

We are certified to ISO9001, ISO13485 for medical quality management, UL, and IATF16949 for automotive quality management, and we follow the IPC-A-610E Class II standard for electronic inspection.

Our dedicated team includes over 300 engineers and production specialists, along with an experienced component sourcing team, ensuring high-quality PCBA products. Whether you require custom, small-batch, or lead-free PCB assembly, KKPCB guarantees reliable results and complete customer satisfaction.

From initial product concept to detailed PCB design and full-scale manufacturing, KKPCB delivers comprehensive product development solutions for clients worldwide. We combine industry expertise, advanced design tools, and proven engineering practices to provide highly reliable and cost-effective solutions that meet the most demanding technical requirements.

Our PCB design capabilities cover multilayer, high-frequency, HDI, flex, and rigid-flex boards, ensuring every design is optimized for performance and manufacturability. We rigorously apply DFM (Design for Manufacturing) principles, and our designs adhere to IPC-2221 standards, while PCB assembly complies with IPC-A-610 standards. This ensures your products are not only high-performing but also fully manufacturable, on-time, and within budget.

With KKPCB, you gain a trusted partner who supports your project through every stage—from concept, schematic, and layout to prototyping, assembly, and testing—delivering designs that exceed expectations across industries.